A seaweed seedling raising shell washing machine

A washing machine and shell washing technology, which is applied in the field of seaweed nursery shell washing machine, to save time, solve the problem of random placement of shells, and reduce the cost of employment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

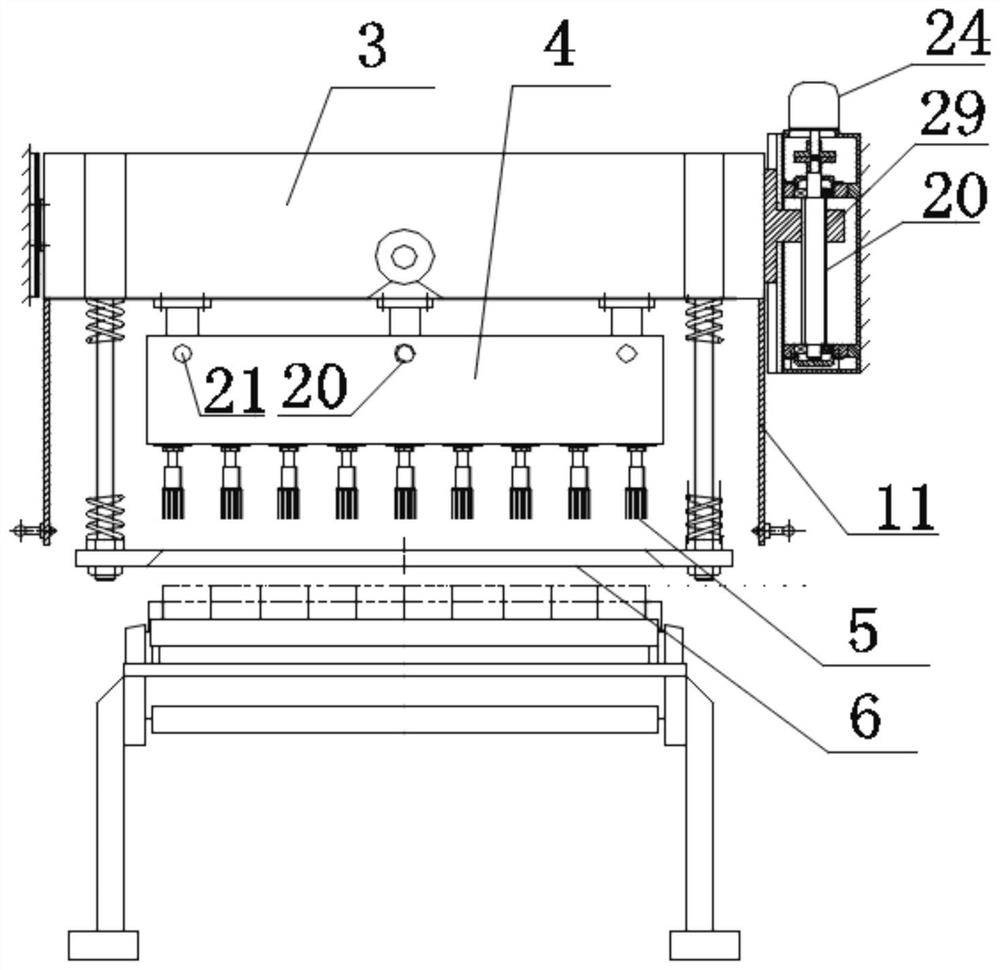

[0048] Put the inner side of the shells upwards and arrange them in a square plastic basket in sequence. The height of the basket is basically the same as the average height of the shells (a little higher or lower will not affect the washing), and the hollow structure. In this way, the scattered shells are placed in a frame in the pool. The advantage is that the washing of a single shell becomes the washing of the whole basket of shells, and the shells only need to be arranged once during the entire seedling cultivation period, unlike the traditional method. Shells have to be rearranged every time they are washed.

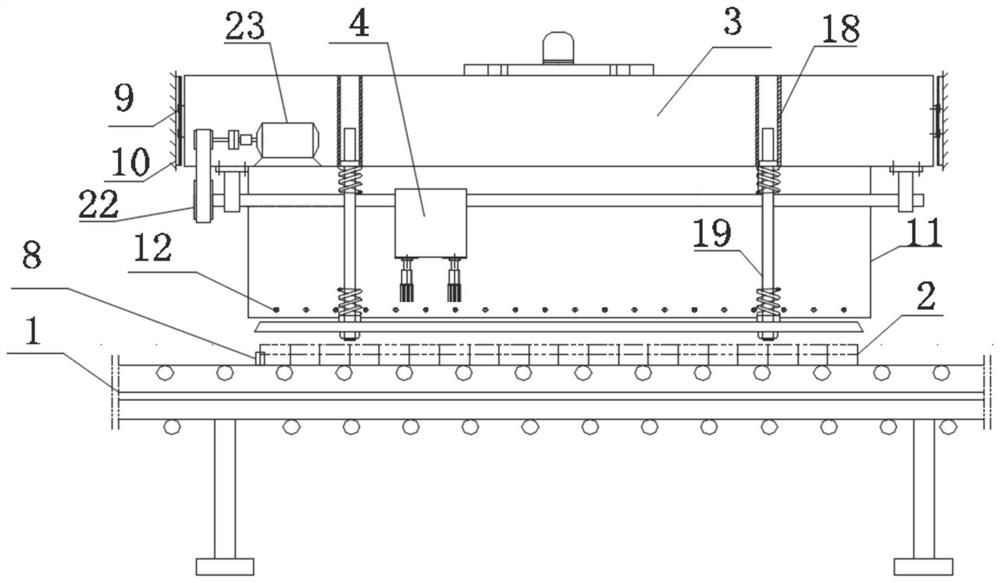

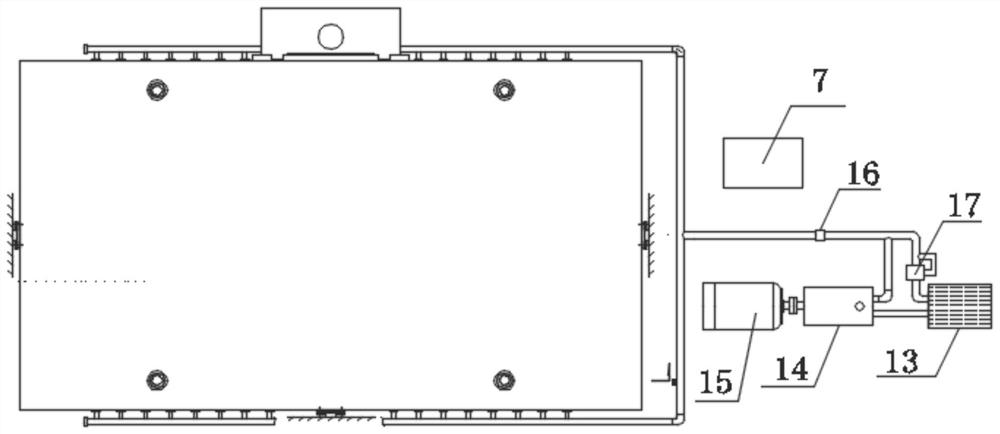

[0049] Put the shells in the plastic basket 2 on the conveyor belt of the conveyor 1. After the square plastic basket 2 reaches the working position, the photoelectric sensor 8 generates a signal, and the electric control device 7 controls the motor of the conveyor 1 to stop rotating, and then the conveyor belt stops. movement, while the electric control device 7 s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com