Treatment device and method for degradation-resistant organic wastewater

A technology for organic wastewater treatment and refractory degradation, which is applied in mixers with rotary stirring devices, chemical instruments and methods, and dissolution. quality, increase mixing efficiency, and improve the effect of degradation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

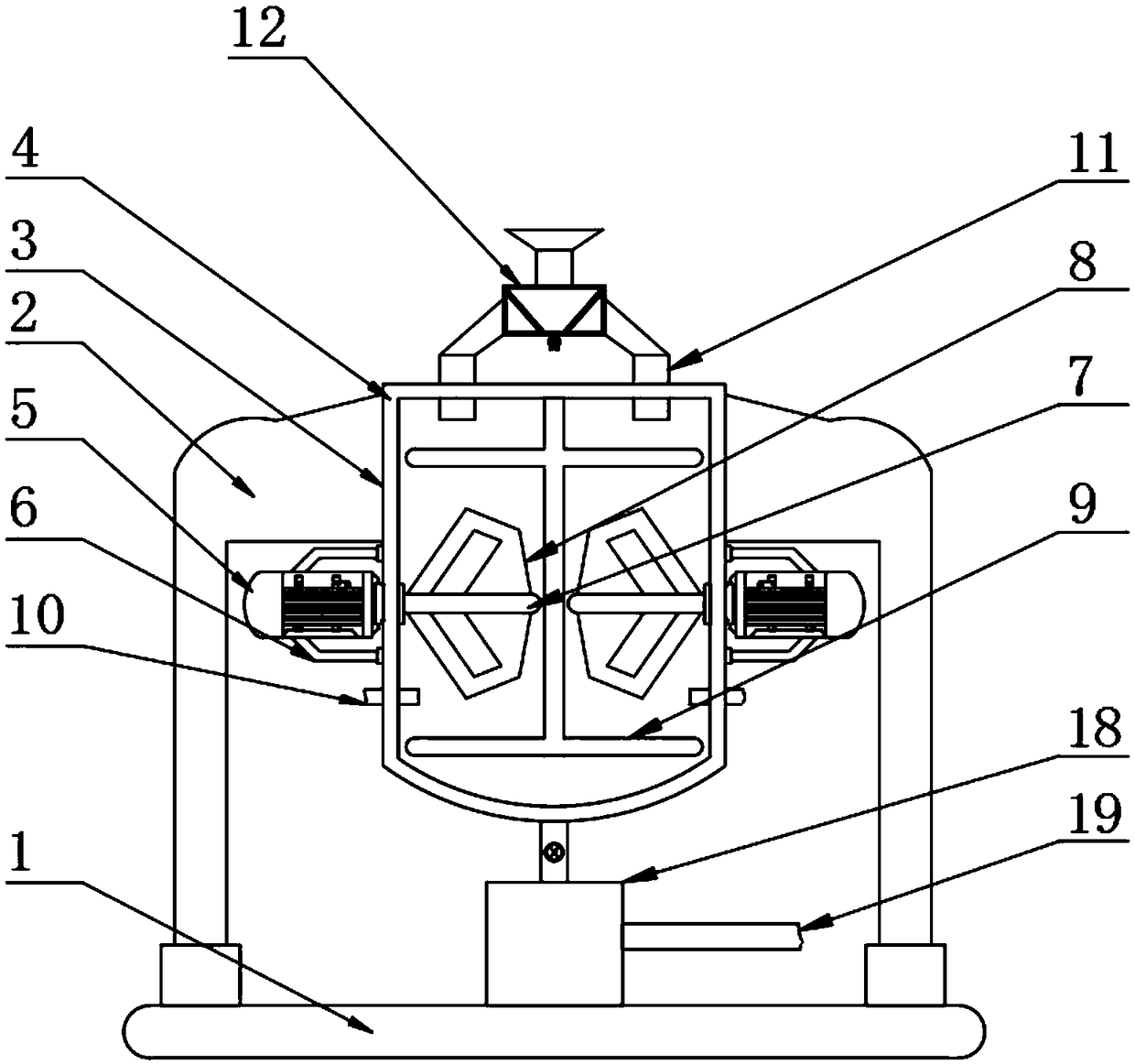

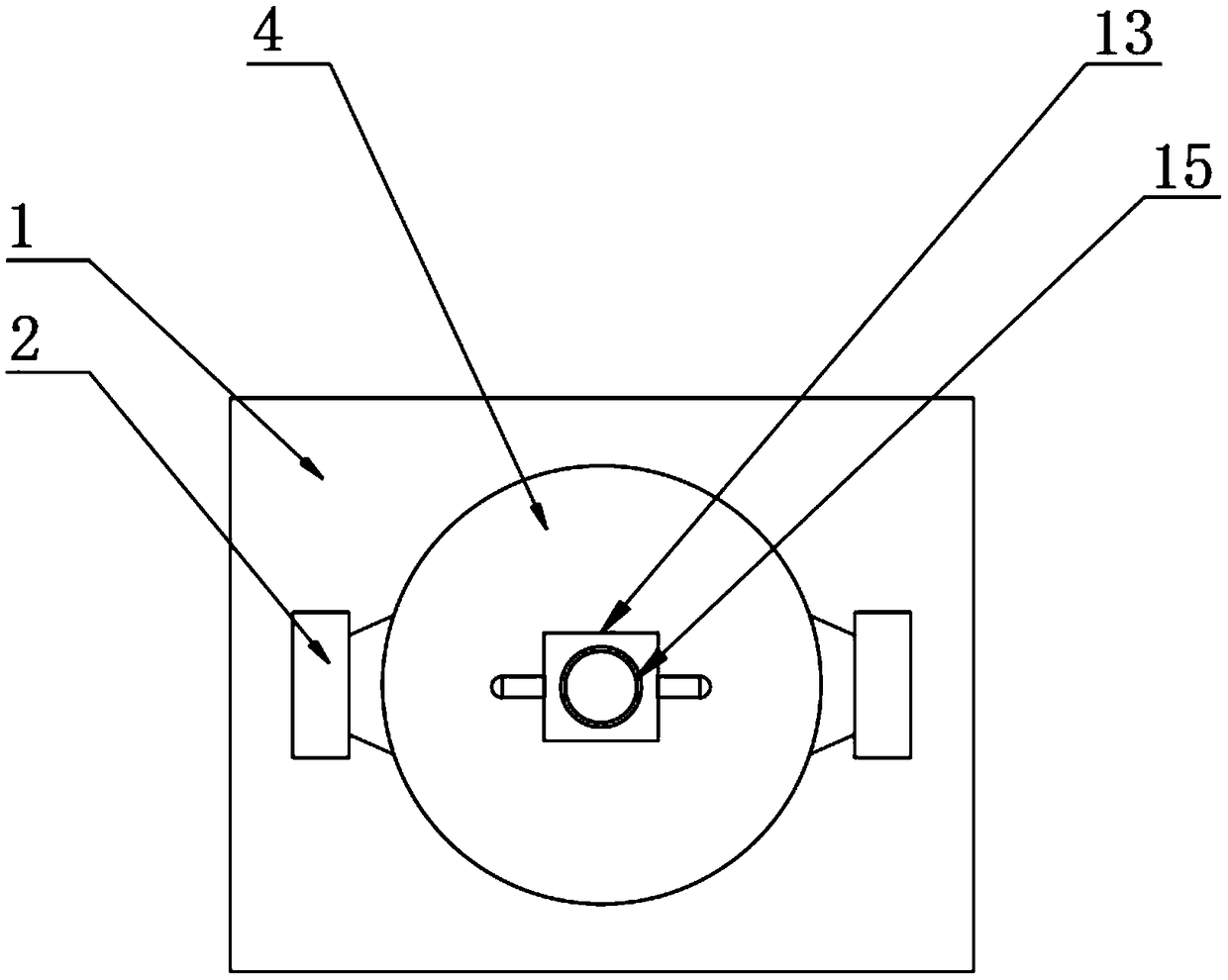

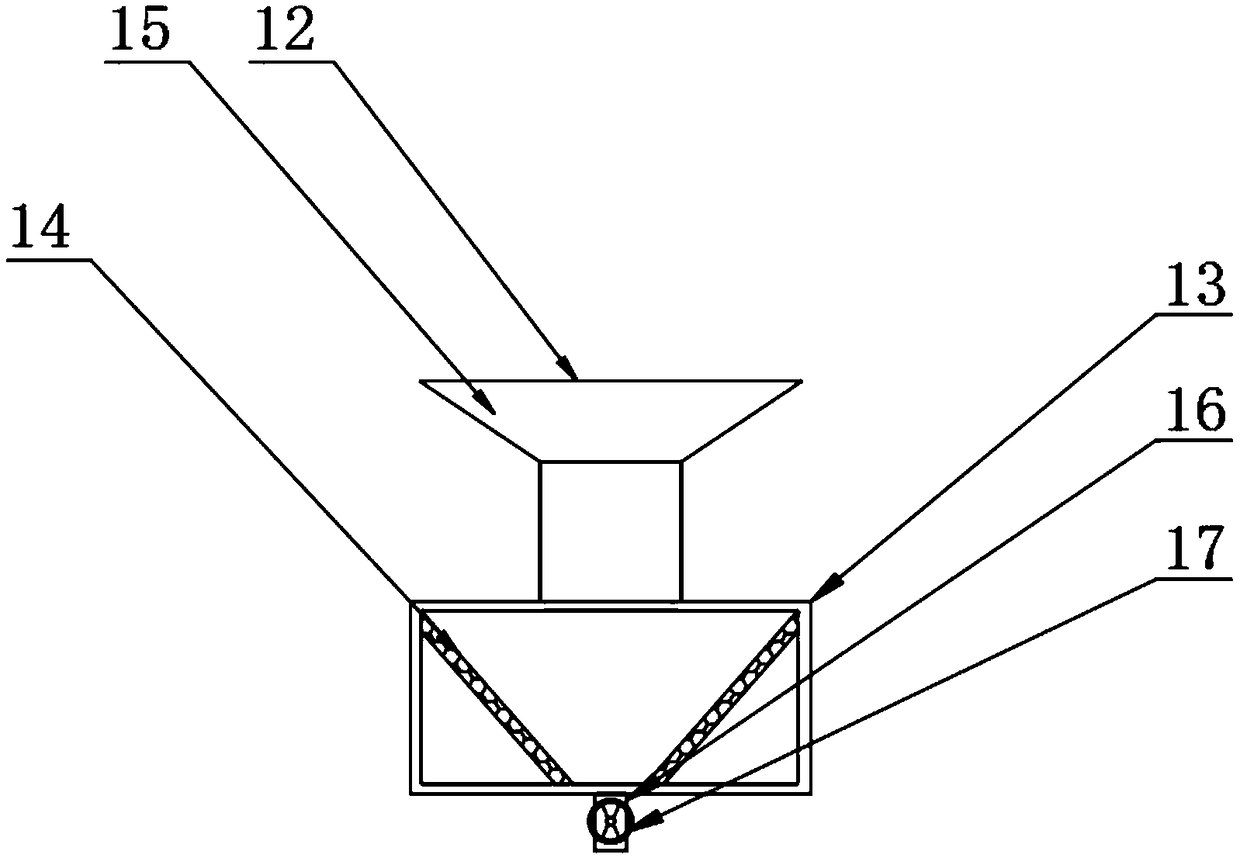

[0028] The present invention provides such Figure 1-3 A refractory organic wastewater treatment device shown includes a base 1, a support rod 2 is provided on the top of the base 1, a heating device 3 is provided on one side of the support rod 2, and the heating device 3 includes a heating box 4, Both sides of the heating box 4 are provided with servo motors 5, the outside of the servo motor 5 is provided with a support frame 6, the support frame 6 is fixedly connected with the heating box 4, and a rotating shaft 7 is provided on one side of the servo motor 5, One side of the rotating shaft 7 is provided with a stirring paddle 8, and the inside of the heating box 4 is provided with a heating rod 9. , through the heating device 3, the waste water enters the inside of the heating box 4, the decomposition liquid is transported to the waste water through the liquid inlet pipe 10, the heater and the servo motor 5 are turned on, and the two servo motors 5 drive the stirring paddle ...

Embodiment 2

[0038] A method for treating refractory organic wastewater, comprising the refractory organic wastewater treatment device, further comprising the following steps:

[0039] S1: waste water enters into the heating box 4;

[0040] S2: transport the decomposition liquid to the waste water through the liquid inlet pipe 10;

[0041] S3: Turn on the heater and the servo motor 5, the two servo motors 5 drive the stirring paddle 8 to rotate through the rotating shaft 7, and the heating rod 9 whose cross-sectional shape is set as an I shape heats the waste water, and the waste water is fully heated;

[0042] S4: Before the waste water is degraded, it first enters the filter box 13, and the filter plate 14 filters the impurities;

[0043] S5: Then open the hand valve 17, the generated impurities leak out through the slag discharge pipe 16, and initially filter the waste water;

[0044] S6: The waste water is further filtered through the purifier 18 at the bottom of the heating box 4 . ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com