Device and method for carrying out pipeline acidifying during beverage production

A technology for acid regulation and pipelines, applied in mixing methods, chemical instruments and methods, mixers with rotary stirring devices, etc. problems, to achieve the effect of simple equipment structure, low equipment requirements, and low requirements for daily use and maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

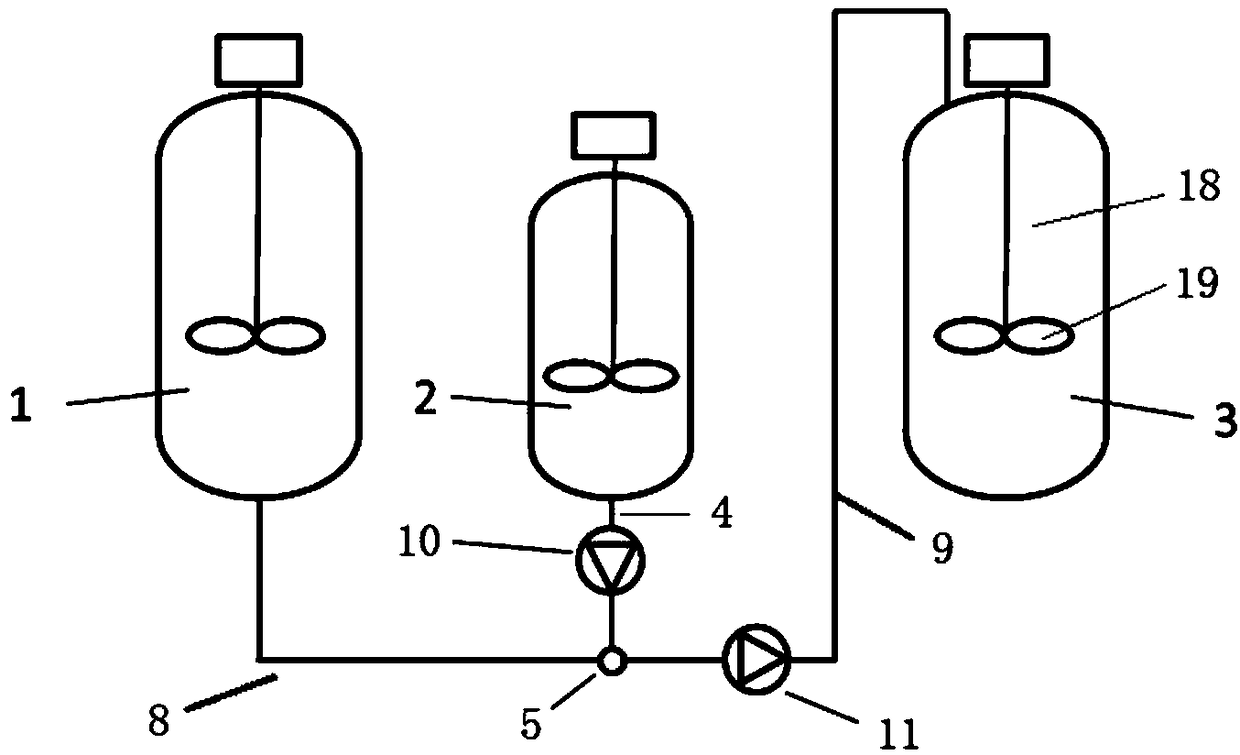

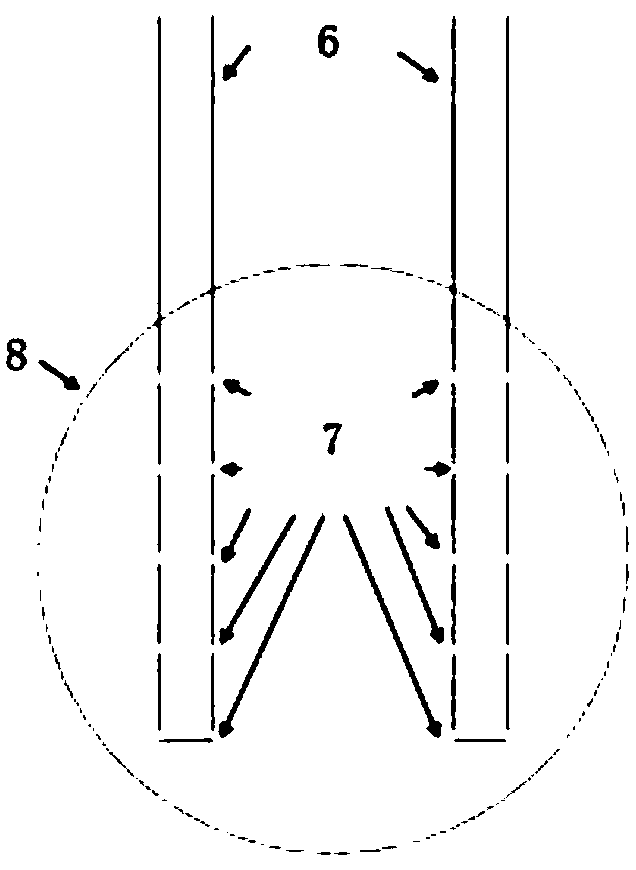

[0032] like figure 1 As shown, a pipeline acid adjustment device in beverage production, including acid feed liquid tank 1 (5000L, equipped with high-speed shear stirring), acid liquid tank 2 (300L, equipped with low-speed stirring) and acid adjustment feed liquid Tank 3 (10000L, equipped with low-speed stirring), the acid liquid tank to be added and the acid liquid tank are provided with a discharge valve 24, and the acid liquid tank is connected with the acid adding nozzle 5 made of stainless steel through the acid liquid discharge path 4, such as image 3 As shown, the acid-adding nozzle is composed of two shunt pipes 6, and the pipe wall of the shunt pipe is provided with a shunt hole 7. One end of the acid-adding nozzle is connected to the acid liquid discharge pipeline, and the other end is inserted into the acid feed liquid to be added. In the discharge pipeline 8, after the acid liquid discharge pipeline merges with the acid feed liquid discharge pipeline to be added, ...

Embodiment 2

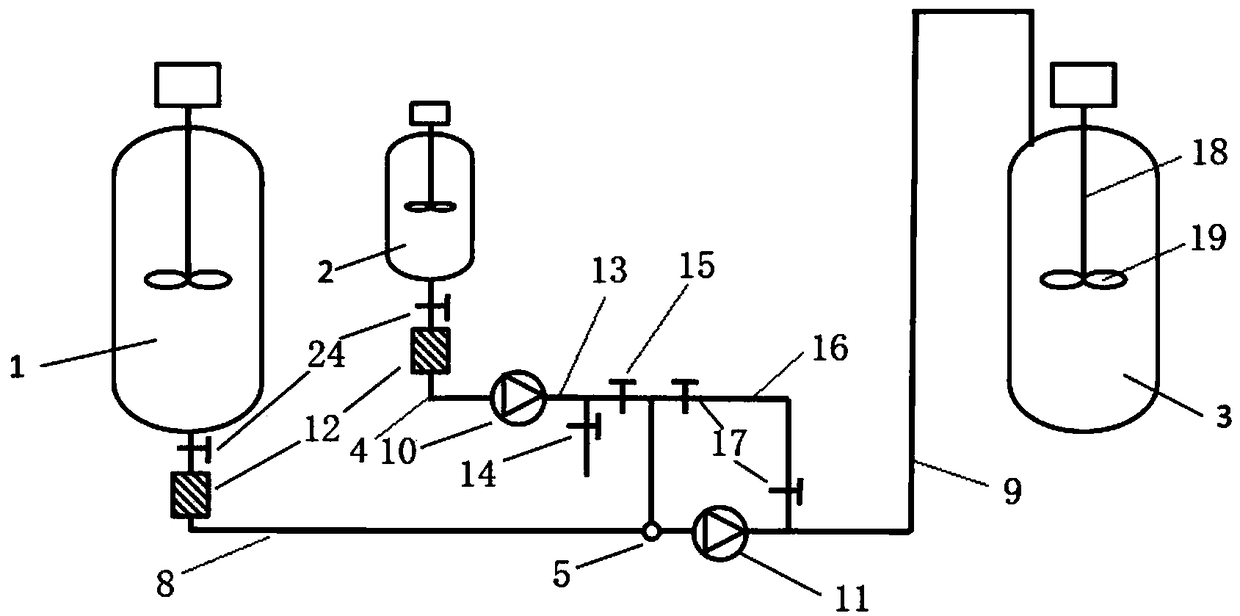

[0043] like figure 2 As shown, a pipeline acid adjustment device in beverage production, including acid feed liquid tank 1 (5000L, equipped with high-speed shear stirring), acid liquid tank 2 (300L, equipped with low-speed stirring) and acid adjustment feed liquid Tank 3 (10000L, equipped with low-speed stirring), the acid liquid tank is connected to the acid-feeding nozzle 5 made of stainless steel through the acid liquid discharge pipeline 4, such as image 3 As shown, the structure of the acid-adding nozzle is the same as in Embodiment 1. The acid liquid discharge pipeline and the acid liquid discharge pipeline to be added are provided with a filter 12, and the acid liquid discharge pipeline is provided with an acid liquid pipeline cleaning bypass 13 with a blowdown valve 14 and a blowdown auxiliary valve 15, And acid nozzle cleaning bypass with bypass valve. Stirring device such as Figure 4 As shown, it includes a stirring shaft 18 and a stirring portion 19, the stirr...

Embodiment 3

[0054] The difference between Example 3 and Example 2 is that the concentration of the acid solution is changed so that the flow ratio between the acid feed solution and the acid solution is controlled at a weight flow ratio of 60:1, and the rest of the process is identical.

[0055] Comparative example Direct pouring of acid to produce acid milk drink

[0056] The raw material formula of the acidic milk drink of this comparative example is the same as that of Example 1, the acid solution tank 2 is canceled, another small tank is taken to dissolve the acid solution, and it is directly poured into the preparation tank of the acid feed liquid to be added for acid adjustment. The specific operations are as follows:

[0057] (1) Ingredients: add an appropriate amount of pure water to the acid material liquid tank to be added, start stirring, and add sweetener, edible colloid, milk powder, emulsifier, salt, etc. to it in turn to obtain a mixture that is uniformly mixed and has no vi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com