An electronic load and working process of a wire electric discharge cutting pulse power supply

A technology of electronic load and electric spark wire, applied in the field of high-frequency pulse power supply, can solve the problems of lack of pulse power supply load, etc., and achieve the effect of improving response speed and flexibility, small conduction resistance, and high control precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The solution of the present invention will be further described in detail below in conjunction with the accompanying drawings.

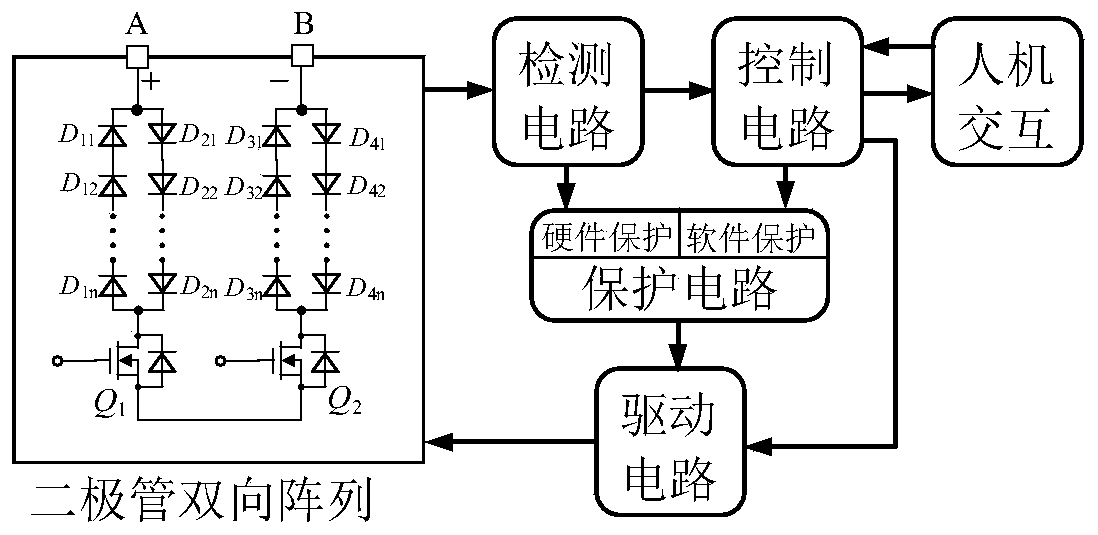

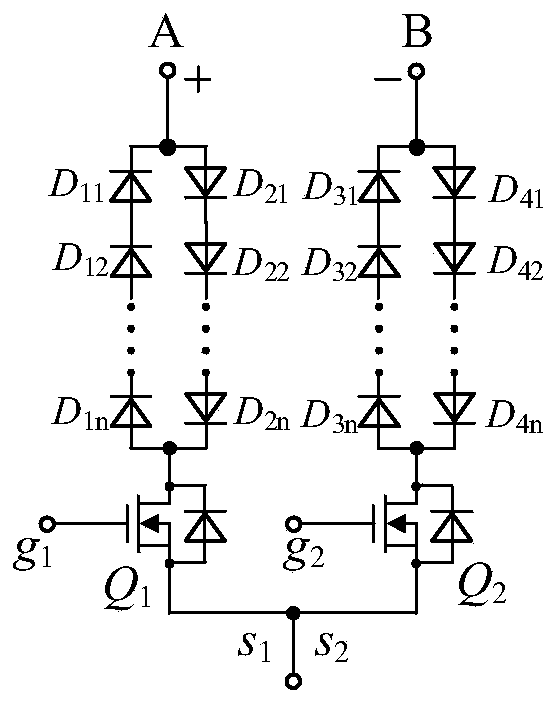

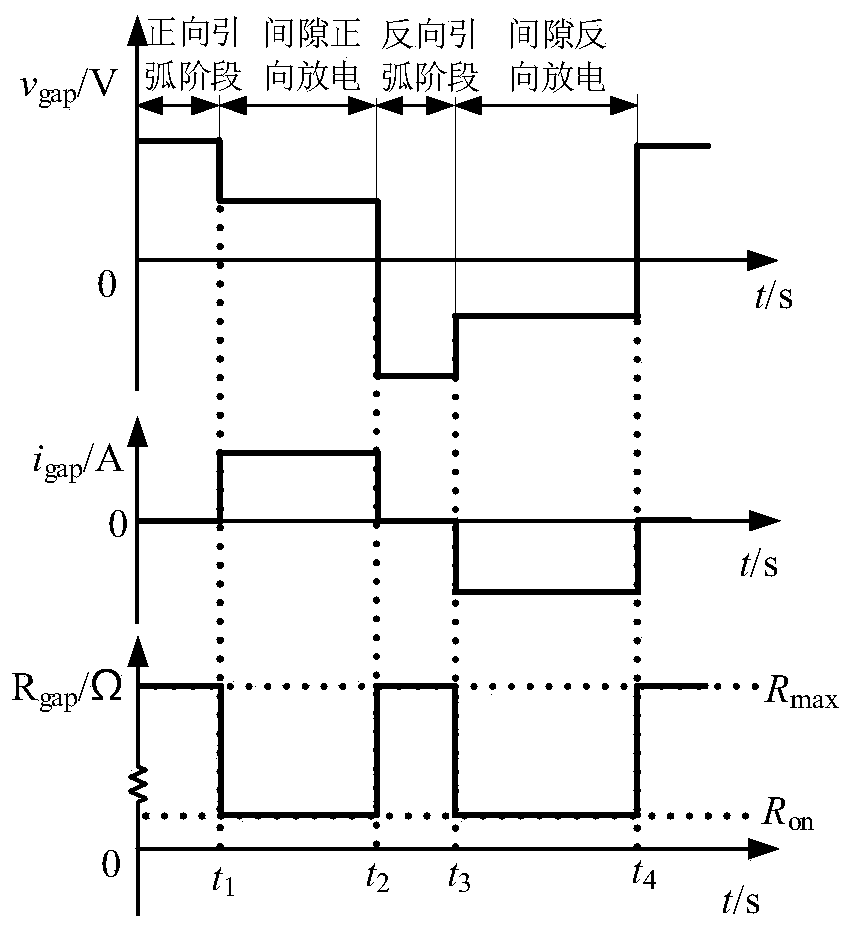

[0020] like figure 1 The electronic load of the wire electric discharge cutting pulse power supply includes a diode bidirectional array, a detection circuit, a control circuit, a protection circuit, a human-computer interaction module and a driving circuit, wherein the diode bidirectional array includes a first diode series branch, a second Two diode series branches, a third diode series branch and a fourth diode series branch, the first diode series branch and the second diode series branch are connected in antiparallel to form a first A parallel branch, the third diode series branch and the fourth diode series branch are connected in reverse parallel to form a second parallel branch, and a connection point of the first parallel branch passes through two MOSFETs connected in series A switch tube or an IGBT is connected to a connection point ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com