Near-zero-emission softening water device and method

A near-zero emission and water softening technology, applied in the direction of ion exchange water/sewage treatment, ion exchange bed cleaning/flushing, etc., can solve the problem of excessive waste water and achieve the effect of reducing regeneration waste water

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

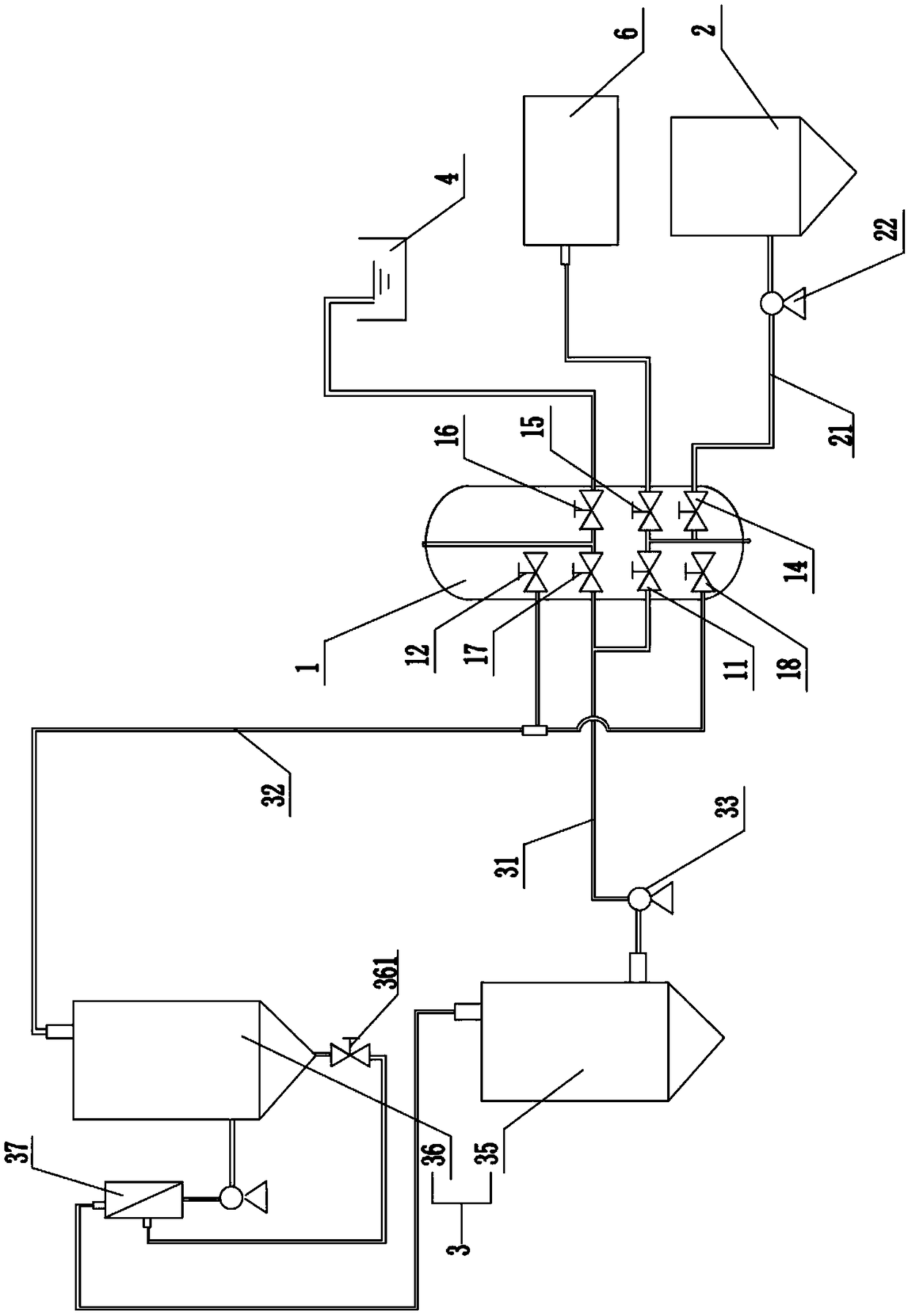

[0034] The present invention will be further described below in conjunction with accompanying drawing.

[0035] like figure 1 As shown, the present invention provides a near-zero discharge softened water equipment, including a resin tank 1 , a regenerant device 2 and a backwash unit 3 . Wherein, the resin tank 1 is filled with sodium ion exchange resin, and the sodium ion exchange resin absorbs calcium and magnesium ions in the water to soften the water. When preparing softened water, the sodium ion exchange resin is constantly exchanging calcium and magnesium cations, and gradually tends to be saturated. When the resin is saturated, it loses its ability to produce water. At this time, the sodium ion exchange resin needs to be regenerated.

[0036] The regenerant device 2 is connected with the resin tank 1 to regenerate the sodium ion exchange resin in the resin tank 1 . The regenerant device 2 includes a regenerant tank and a regenerant provided in the regenerant tank.

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com