White-mud base permeable brick and preparation method thereof

A technology of permeable bricks and white mud, applied in the field of building materials, can solve the problems of aging, emission of greenhouse gases, impact on performance, etc., and achieve the effect of high water permeability and resource saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

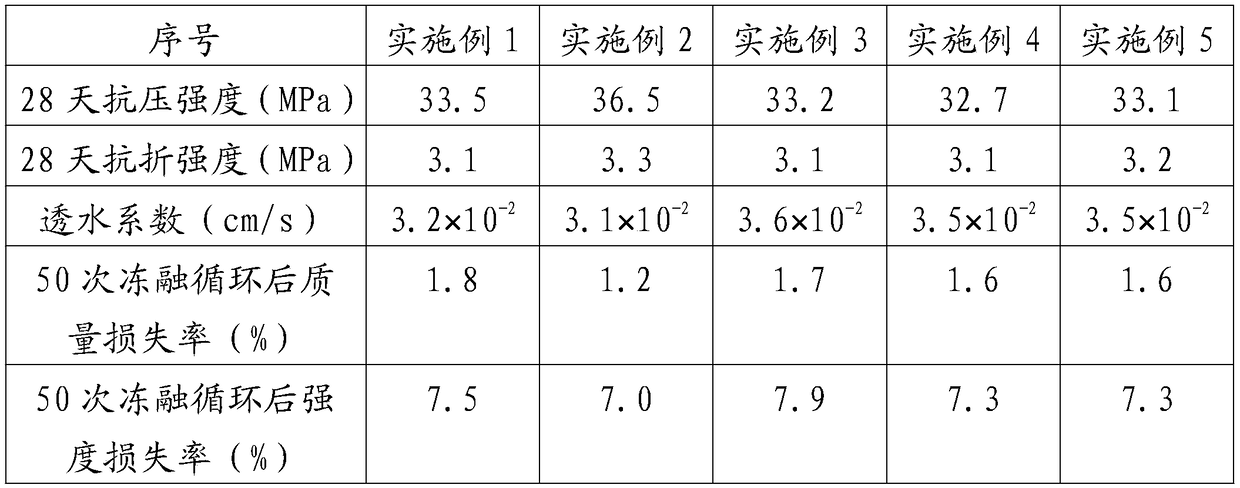

Examples

Embodiment 1

[0058] 1) Add basalt crushed stones of the following two particle sizes into a concrete mixer and mix for 1 minute to obtain aggregate A; one is basalt crushed stones with a mass of 121.6kg and a particle size of 2.5-4mm, and the other is Basalt gravel with a mass of 182.4kg and a particle size of 4.75-9.5mm;

[0059] Then, 33.8kg of lime mud, 13.5kg of cement, 3.4kg of fly ash, 10.1kg of slag, and 6.8kg of metakaolin were added to aggregate A and mixed for 2 minutes to obtain a solid mixture; 0.81kg of phosphoric acid Add it to 23.6kg of water and mix and stir for 2 minutes to obtain a liquid mixture, then add the liquid mixture to the solid mixture and stir for 3 minutes to obtain the base material for preparing white mud-based permeable bricks;

[0060] (2) Pour the base material obtained in step (1) into a mould, and reserve a height of 8-10mm, place the mold on a vibrating table to vibrate for 2-3 seconds, and vibrate to make a permeable brick base;

[0061] (3) Add rive...

Embodiment 2

[0066] 1) Add basalt crushed stones of the following two particle sizes into a concrete mixer and mix for 1 minute to obtain aggregate A; one is basalt crushed stones with a mass of 182.4 kg and a particle size of 2.36-4.75 mm, and the other It is basalt gravel with a mass of 121.6kg and a particle size of 5-8mm;

[0067] Then, the quality is 33.4kg of lime mud, 15.2kg of cement, 1.8kg of fly ash, 5.5kg of slag, 4.9kg of metakaolin into aggregate A and mixed for 2min to obtain a solid mixture; 0.9kg of Phosphoric acid was added to 18.2kg of water, mixed and stirred for 2 minutes to obtain a liquid mixture, and then the liquid mixture was added to the solid mixture and stirred for 3 minutes to obtain the base material for preparing white mud-based permeable bricks;

[0068] (2) Pour the base material obtained in step (1) into a mould, and reserve a height of 8-10mm, place the mold on a vibrating table to vibrate for 2-3 seconds, and vibrate to make a permeable brick base;

[0...

Embodiment 3

[0074] 1) Add the basalt gravel of the following two particle sizes into a concrete mixer and mix for 1 minute to obtain aggregate A; one is basalt gravel with a mass of 243.2kg and a particle size of 2.36-4mm, and the other is Basalt gravel with a mass of 60.8kg and a particle size of 4.75-9.5mm;

[0075] Then, the quality is 33.2kg of lime mud, 11.1kg of cement, 2.8kg of fly ash, 3.9kg of slag, 4.4kg of metakaolin into aggregate A and mixed for 2min to obtain a solid mixture; 0.7kg of Phosphoric acid was added to 13.9kg of water, mixed and stirred for 2 minutes to obtain a liquid mixture, and then the liquid mixture was added to the solid mixture and stirred for 3 minutes to obtain the base material for preparing white mud-based permeable bricks;

[0076](2) Pour the base material obtained in step (1) into a mould, and reserve a height of 8-10mm, place the mold on a vibrating table to vibrate for 2-3 seconds, and vibrate to make a permeable brick base;

[0077] (3) Add the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com