MgO-Al2O3-ZnO-based high-temperature high-emissivity filler and preparation method thereof

A high-emissivity, al2o3 technology, applied in the field of infrared radiation filler preparation, can solve the problems of low average emissivity, harmful heavy metals, low temperature resistance, etc., and achieves simple and easy preparation process, cheap raw materials, good thermal shock performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

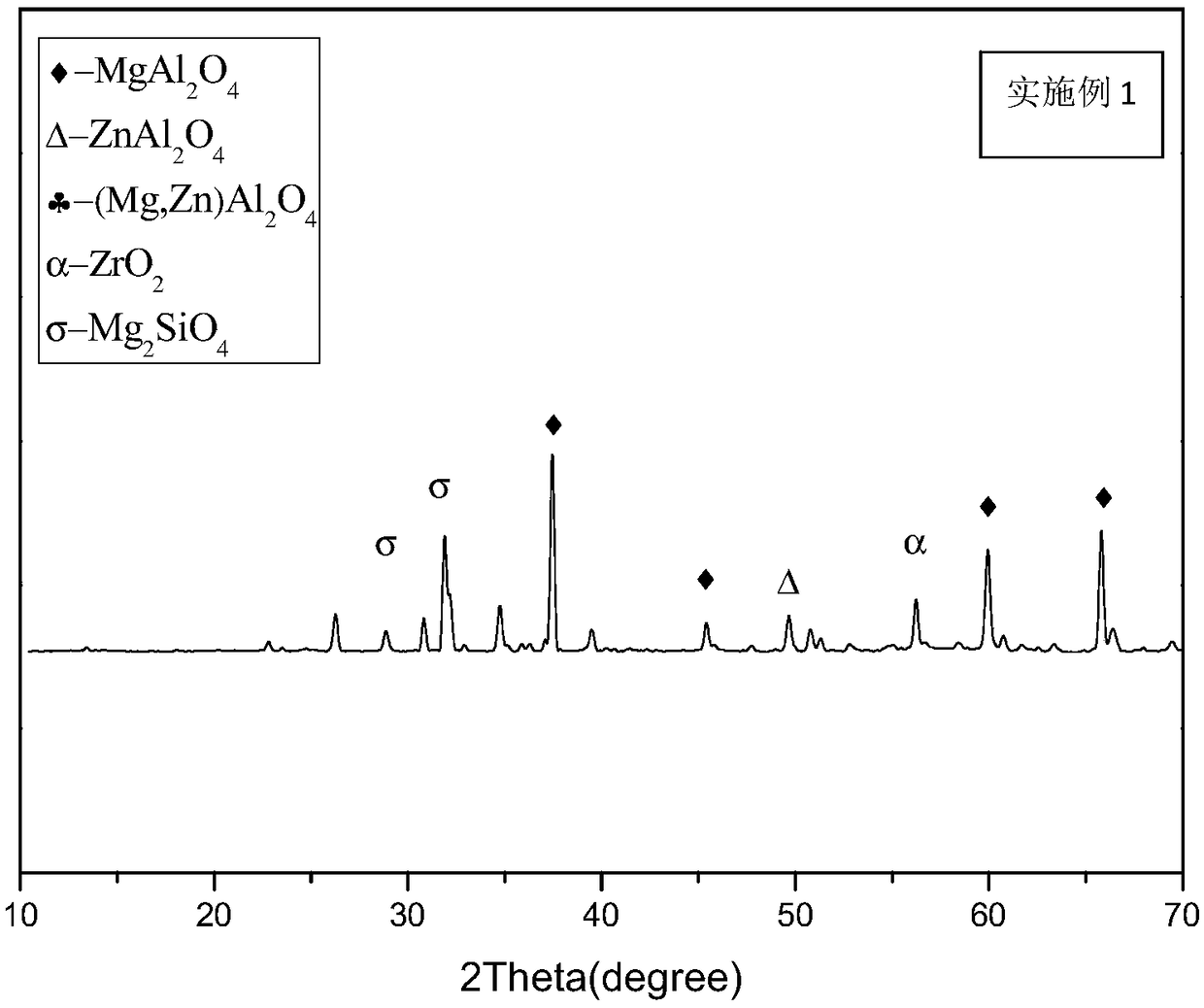

Embodiment 1

[0037] A high temperature resistant and high emissivity filler, in terms of mass percentage, containing SiC 10wt% and ZrO 2 10wt%, the rest is MgO, Al 2 O 3 And ZnO; among them, MgO, Al 2 O 3 The molar ratio with ZnO is 1:1:0.2.

[0038] The specific steps for preparing the high temperature resistant and high emissivity filler are as follows:

[0039] (1) Preparation of raw material mixed powder: According to the composition of filler powder (MgO, Al 2 O 3 The molar ratio of ZnO is 1:1:0.2, SiC and ZrO 2 Respectively account for 10wt% of the total mass of the powder), weigh the raw materials with an electronic balance, of which 1.1657g MgO and Al 2 O 3 2.9726g, ZnO 0.7431g, SiC 0.4882g and ZrO 2 0.4882g;

[0040] (2) Ball milling of raw material mixed powder: the weighed raw material is mixed powder, grinding ball (ZrO 2 Ball 9g) and deionized water (17g) are mixed according to the mass ratio of 1:1.5:3, put into the ball mill, and ball milled at 150r / min for 6h;

[0041] (3) Dryi...

Embodiment 2

[0047] A high temperature resistant and high emissivity filler, in terms of mass percentage, containing SiC 10wt% and ZrO 2 10wt%, the rest is MgO, Al 2 O 3 And ZnO; among them, MgO, Al 2 O 3 The molar ratio of ZnO is 1:1:0.8.

[0048] The specific steps for preparing the high temperature resistant and high emissivity filler are as follows:

[0049] (1) Preparation of raw material mixed powder: According to the composition of filler powder (MgO, Al 2 O 3 The molar ratio of ZnO is 1:1:0.8, SiC and ZrO 2 Respectively account for 10wt% of the total mass of the powder), weigh the raw materials with an electronic balance, of which 1.1657g MgO and Al 2 O 3 2.9726g, ZnO 2.9726g, SiC 2g and ZrO 2 2g;

[0050] (2) Ball milling of raw material mixed powder: the weighed raw material is mixed powder, grinding ball (ZrO 2 Ball 12g) and deionized water (48g) are mixed according to the mass ratio of 1:1:4, put into the ball mill, and ball milled at 200r / min for 6h;

[0051] (3) Drying of raw mat...

Embodiment 3

[0057] A high temperature resistant and high emissivity filler, in terms of mass percentage, containing 15wt% SiC and ZrO 2 15wt%, the rest is MgO, Al 2 O 3 And Fe 2 O 3 ; Among them, MgO, Al 2 O 3 The molar ratio of ZnO to ZnO is 1:1:1.

[0058] The specific steps for preparing the high temperature resistant and high emissivity filler are as follows:

[0059] (1) Preparation of raw material mixed powder: According to the composition of filler powder (MgO, Al 2 O 3 The molar ratio of ZnO is 1:1:1.3, SiC and ZrO 2 Respectively account for 15wt% of the total mass of the powder), weigh the raw materials with an electronic balance, of which 3.216g MgO and Al 2 O 3 4.1008g, ZnO8.6832g, SiC2g and ZrO 2 2g;

[0060] (2) Ball mill of raw material mixed powder: the weighed mixed powder, grinding ball (ZrO 2 Ball (40g) and deionized (80g) water are mixed according to the mass ratio of 1:2:4, put into the ball mill, and ball milled for 8h at a speed of 180r / min;

[0061] (3) Drying of raw ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com