High nitrogen type volatile solvent colloid gunpowder

A technology of volatile solvents and colloids, which is applied in the field of colloidal gunpowder with high nitrogen volatile solvents, can solve the problems of low safety, poor moisture resistance, and low moisture absorption rate, and achieve the effects of prolonging storage time, improving moisture resistance, and high safety performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

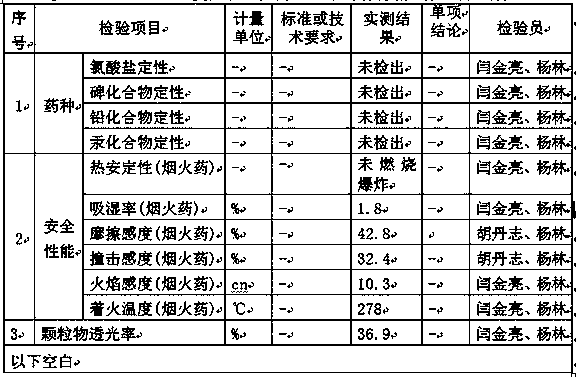

Image

Examples

Embodiment 1

[0023] Take 60 parts by weight of ammonium perchlorate, 10 parts by weight of nitroguanidine, 30 parts by weight of ammonium dichromate, 50 parts by weight of nitrated starch, 40 parts by weight of NC, 1 part by weight of diphenylamine, 1 part by weight of camphor oil, and 1 part by weight of water. Parts by weight. The above-mentioned components are mixed and processed according to the preparation process to obtain the present invention.

Embodiment 2

[0025] Take 30 parts by weight of ammonium perchlorate, 20 parts by weight of nitroguanidine, 60 parts by weight of ammonium dichromate, 80 parts by weight of nitrated starch, 70 parts by weight of NC, 1.5 parts by weight of diphenylamine, 1.5 parts by weight of camphor oil, and 1.5 parts by weight of water. Parts by weight. The above-mentioned components are mixed and processed according to the preparation process to obtain the present invention.

[0026] Among the above components, nitroguanidine CH 4 N 4 O 2 It is a strong oxidant, also a high-nitrogen substance, with a nitrogen content of 53.8%. It has the characteristics of not dissolving moisture in the air, not absorbing moisture, and decomposing and exploding at high temperature. It has higher stability after being added to the compatibility of firework agents. Increasing the energy of the pharmaceutical composition is a usable component of the high-energy mixture. At the same time, it can also be used as a smokeless red...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Flash point | aaaaa | aaaaa |

| Melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com