Fabric printing and dyeing pre-wetting device and method

A fabric, printing and dyeing pool technology, applied in the field of fabric or fabric printing and dyeing, can solve the problems of decreased dye concentration, affecting printing and dyeing quality, poor pre-wetting effect, etc., to achieve the effect of eliminating wrinkles and improving printing and dyeing quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

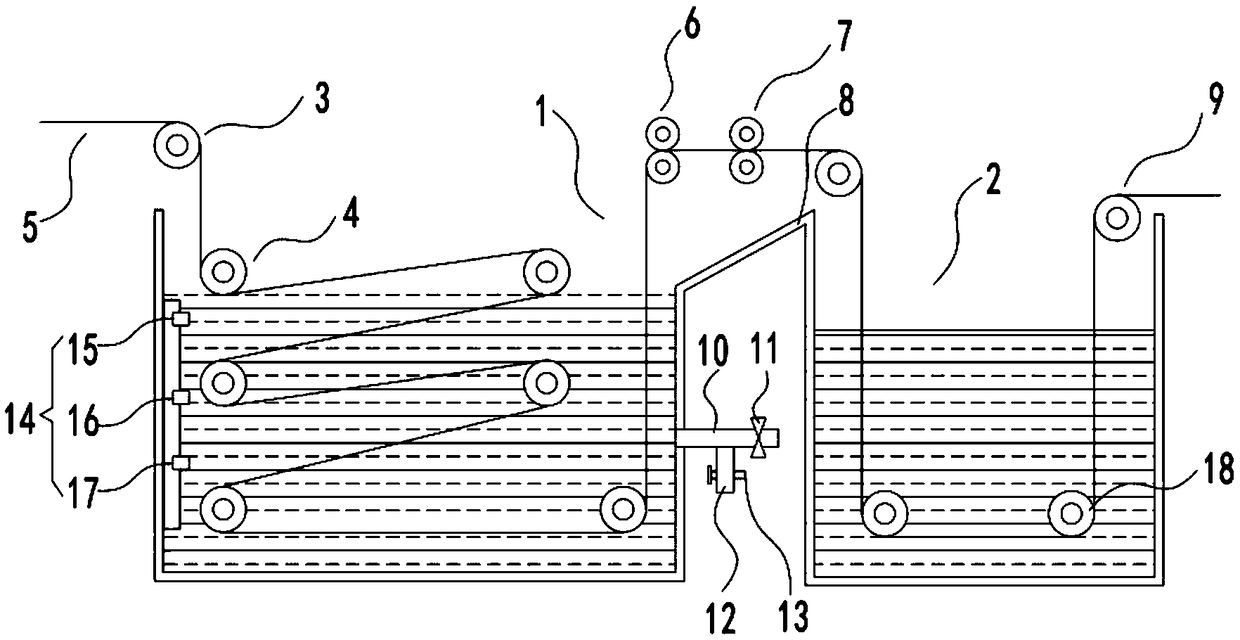

[0024] See figure 1 In the embodiment of the present invention, a fabric printing and dyeing pre-wetting device includes a prepreg tank 1, a printing and dyeing tank 2, and a feeding guide roller 3 and a discharging guide roller 9 for guiding the movement of the cloth 5. The prepreg tank 1 and the dyeing tank 2 are respectively installed with a soaking guide roller group 4 and a printing and dyeing guide roller group 18, the fabric 5 passes through the feed guide roller 3 and is wound around the soaking guide roller group 4 and then enters the dyeing tank 2 and bypasses the dyeing tank The printing and dyeing guide roller set 18 in 2 is then output by the discharging guide roller 9. Of course, in this embodiment, there are also a discharging roller for discharging and a receiving roller for receiving, in order to make the technical solution more Concise, this technical solution does not illustrate it. Generally speaking, its working principle is as follows: the cloth 5 output fr...

Embodiment 2

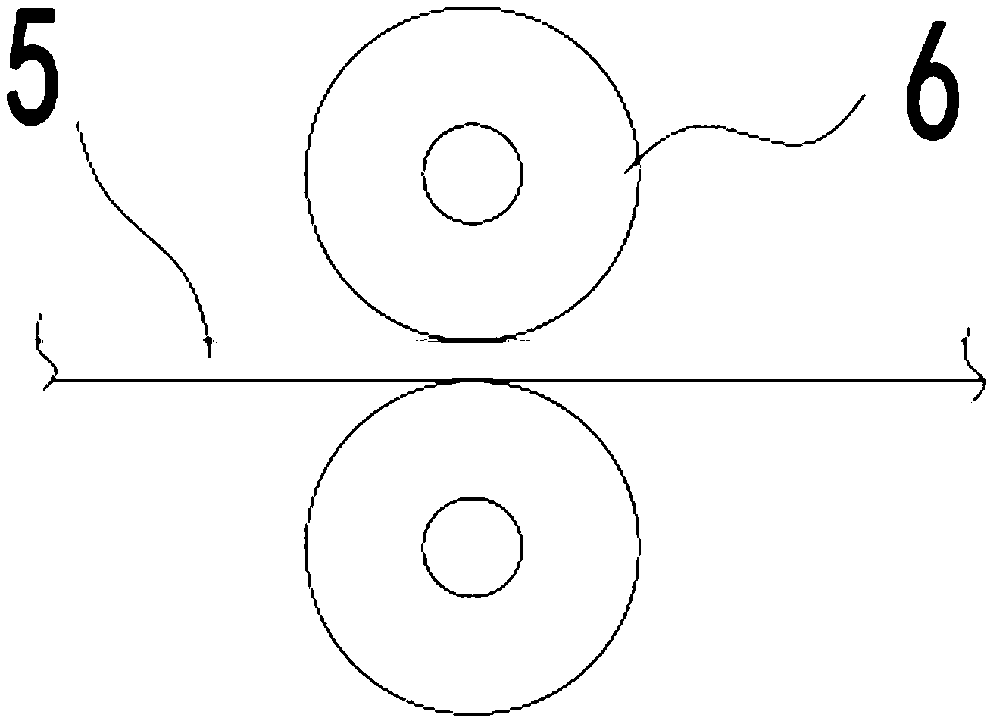

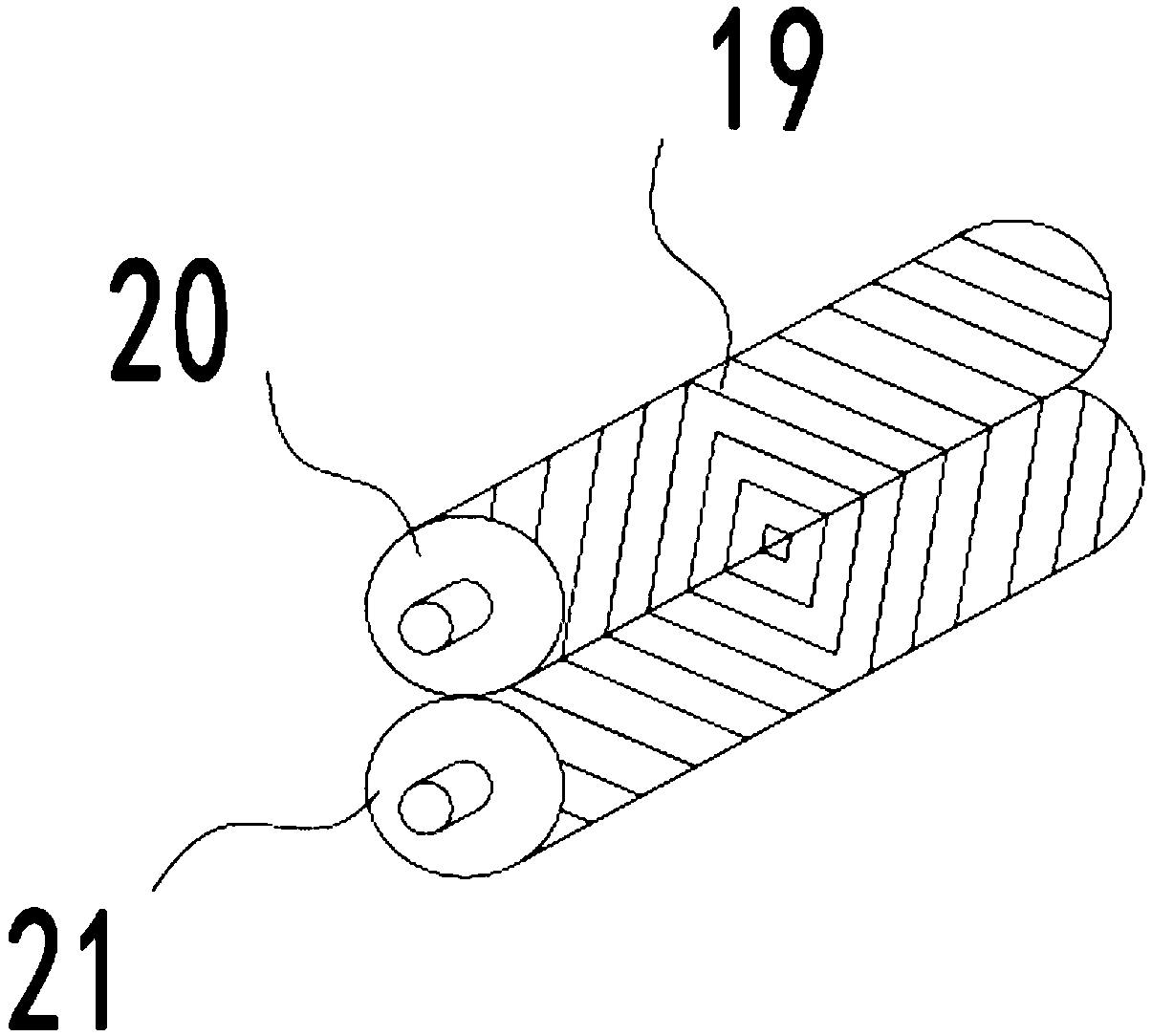

[0027] See figure 2 with 3 In this embodiment, the squeeze roller 6 and the smoothing roller 7 in the embodiment 1 are explained, and the details are as follows:

[0028] The squeeze roller 6 is composed of a pair of relatively rotating rollers. The cloth 5 passes between the rollers. The gap between the rollers is smaller than the thickness of the cloth 5. When working, the water in the cloth 5 can be squeezed out. , And drip on the diversion slope 8, and finally return to the prepreg tank 1.

[0029] The smoothing roller 7 includes a relatively rotating roller body 20 and a roller body 21. The cloth 5 passes between the roller body 20 and the roller body 21. The surfaces of the roller body 20 and the roller body 21 are both provided. There are multiple diagonal lines 19, which spread from the middle of roller body one 20 and roller body two 21 to both ends. The wrinkles on the surface of the cloth 5 can be stretched to both sides by the outward spreading diagonal lines 19 to ens...

Embodiment 3

[0031] See figure 1 with 4 In order to enrich the functions of the prepreg tank 1 and make the prepreg operation more convenient, a liquid level sensor 14 for detecting the liquid level is installed in the prepreg tank 1. The liquid level sensor 14 is composed of high-level sensors 15, which are distributed up and down. The middle position sensor 16 and the low position sensor 17 are composed. The high position sensor 15, the middle position sensor 16 and the low position sensor 17 are all connected to the central control host. One side of the prepreg tank 1 is also connected with a water inlet pipe 10, which is connected to an external storage The water mechanism is connected. The inlet pipe 10 is equipped with an inlet pipe solenoid valve 11 controlled by the central control host. When the water level in the prepreg pool 1 is lower than the low level sensor 17, the low level sensor 17 sends a signal to the central control host, and the central control host receives After the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com