Production method of thermal-sensitive stencil base paper

A production method and technology for base paper, applied in special paper, paper, papermaking, etc., can solve the problems of reducing paper thickness, low production efficiency, and fiber diameter, etc., so as to improve paper porosity, increase the number of suitable printing sheets, and improve ink absorption. effect of ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

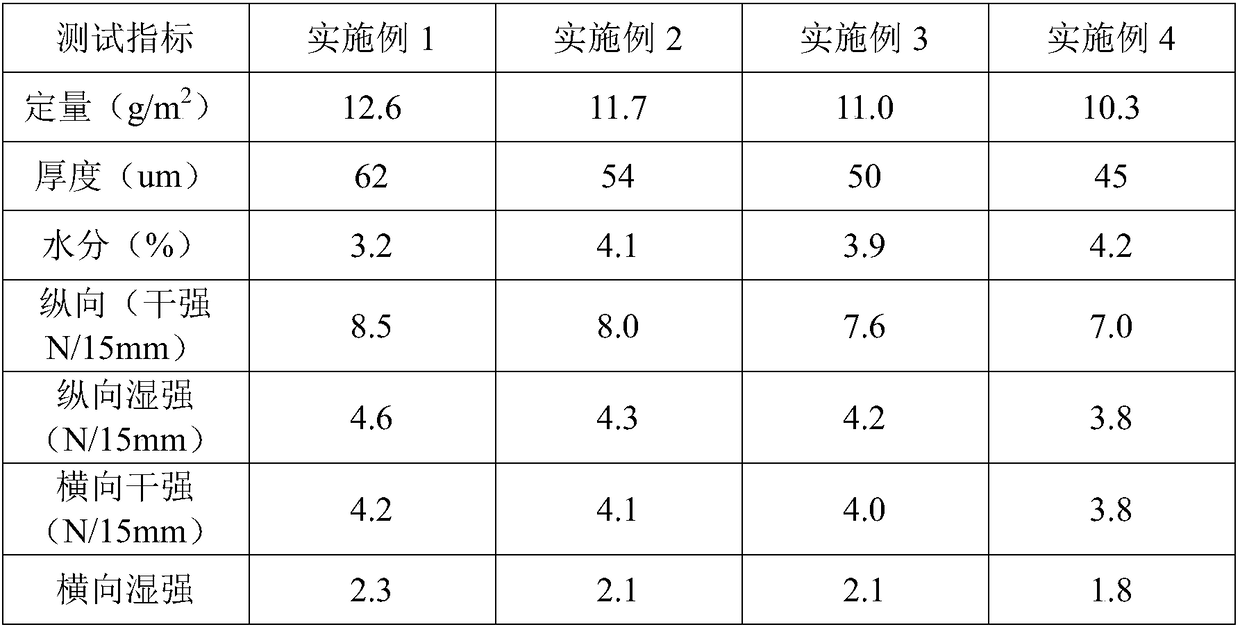

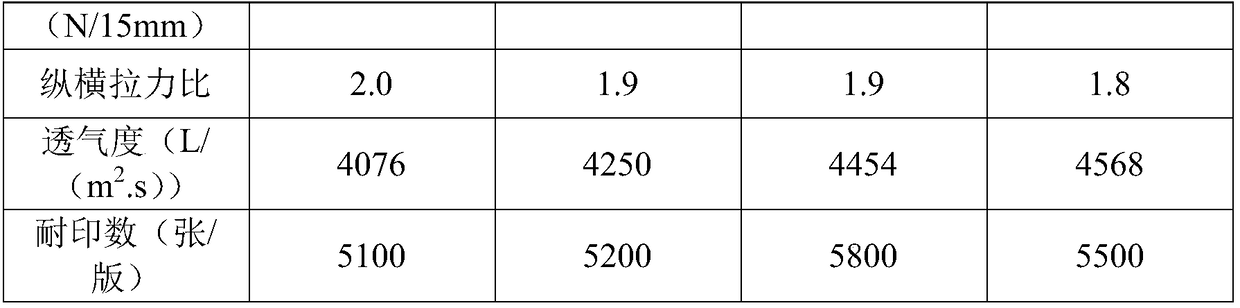

Examples

Embodiment 1

[0038] (1) Mix the linear structure PET fiber and the T-type PET fiber according to the ratio of mass ratio 9:1 until the beating degree is 7°SR for later use, and the Beimu paddle is beating until the beating degree is 42°SR, and the wet weight is 10g for later use;

[0039] (2) Mix 70% mixed PET fiber and 30% Beimu wood pulp in the pulp mixing tank, add dispersant and enter the pulp forming tank for standby.

[0040] 2. Paper flow and wet paper web forming

[0041] (1) After the slurry in the slurry tank is diluted by the slurry pump, it passes through the desander to remove heavy impurities, and after the second dilution, it uses the pressure screen to remove coarse impurities. The purified slurry uses two pipelines to enter the double channel respectively. Headbox; control the slurry volume ratio of the two pipelines to be 1:0.8, and the flow velocity ratio to be 1:1.01.

[0042] (2) The double-channel headbox slurry is mixed after passing through the bleaching sheet, deh...

Embodiment 2

[0049] 1. Slurry preparation

[0050] (1) Mix linear structure PET fiber and T-type PET fiber according to the ratio of mass ratio 8:2 and beat until the degree of beating is 10 ° SR for later use, and Beimu paddle is beaten until the degree of beating is 47 ° SR, and the wet weight is 8g for later use;

[0051] (2) Mix 65% mixed PET fiber and 35% Beimu wood pulp in the pulp mixing tank, add dispersant and enter the pulp forming tank for standby.

[0052] 2. Paper flow and wet paper web forming

[0053] (1) After the slurry in the slurry tank is diluted by the slurry pump, it passes through the desander to remove heavy impurities, and after the second dilution, it uses the pressure screen to remove coarse impurities. The purified slurry uses two pipelines to enter the double channel respectively. Headbox; control the slurry volume ratio of the two pipelines to be 1:1.2, and the flow velocity ratio to be 1:1.03.

[0054] (2) The double-channel headbox slurry is mixed after pa...

Embodiment 3

[0061] 1. Slurry preparation

[0062] (1) The linear structure PET fiber and the T-type PET fiber are mixed according to the ratio of mass ratio 7:3 until the beating degree is 8°SR for later use, and the Beimu paddle is beaten until the beating degree is 45°SR, and the wet weight is 8.8g for later use;

[0063] (2) Mix 60% mixed PET fiber and 40% Beimu wood pulp in the pulp mixing tank, add dispersant and enter the pulp forming tank for standby.

[0064] 2. Paper flow and wet paper web forming

[0065] (1) After the slurry in the slurry tank is diluted by the slurry pump, it passes through the desander to remove heavy impurities, and after the second dilution, it uses the pressure screen to remove coarse impurities. The purified slurry uses two pipelines to enter the double channel respectively. Headbox; control the slurry volume ratio of the two pipelines to be 1:1, and the flow velocity ratio to be 1:1.03. .

[0066] (2) The double-channel headbox slurry is mixed after p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com