An Assembled Vertical Shield Ring Foundation Pile and Its Construction Method

A prefabricated and vertical technology, applied in infrastructure engineering, sheet pile walls, buildings, etc., can solve the problem of a large number of steel bar joints, and achieve the effect of improving construction quality, reducing waterproof construction, and reducing construction costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The circumferential reinforced concrete prefabricated segments (1) are connected by high-strength straight bolts (2), and the vertical reinforced concrete prefabricated segments (1) are connected by high-strength curved bolts (3). The standard module (12) is provided with tenons and grooves up and down, which is convenient for assembling with the prefabricated concrete segments at the upper and lower parts. The lower part of the pile bottom module (10) is an angled steel blade foot (11), which is convenient for cutting soil and sinking. The pile bottom module has a prefabricated pile wall groove (15), and a reinforced concrete bottom plate (16) is inserted into the groove to ensure that the bottom plate is well combined with the main body of the pile.

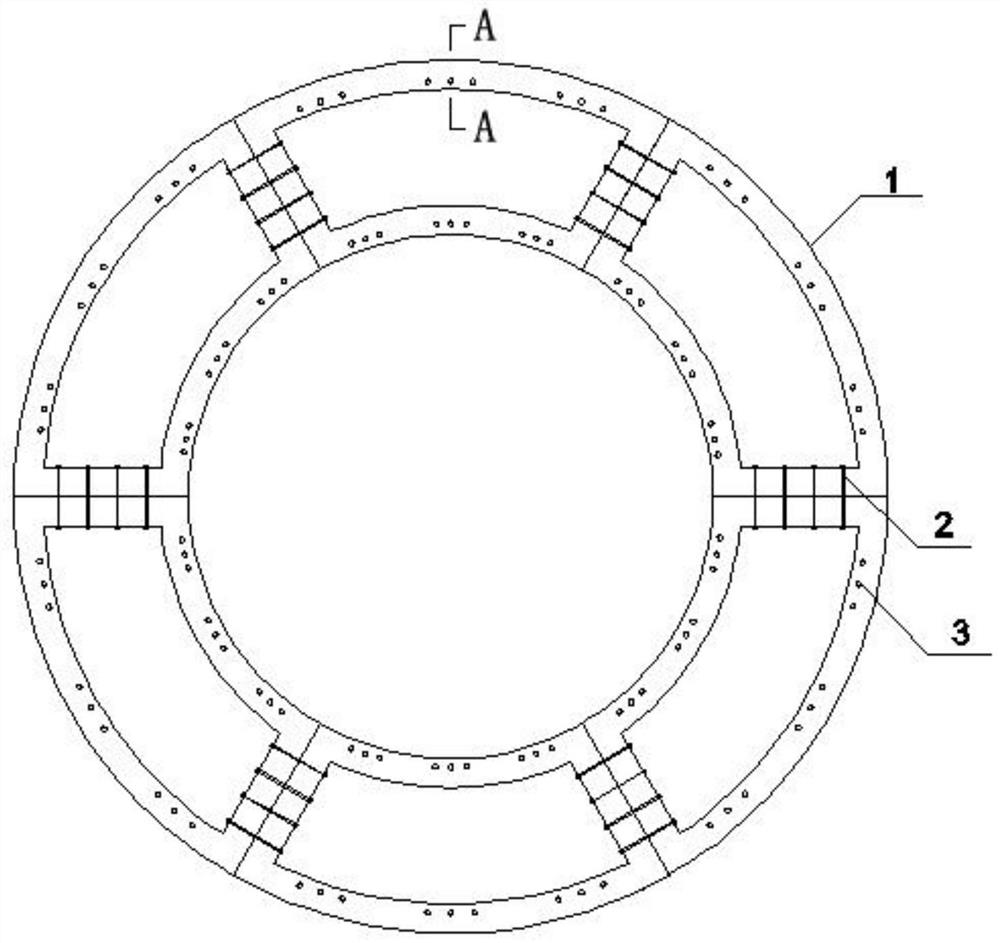

[0031] Such as figure 1 Shown is the top view of the assembled vertical shield ring foundation pile.

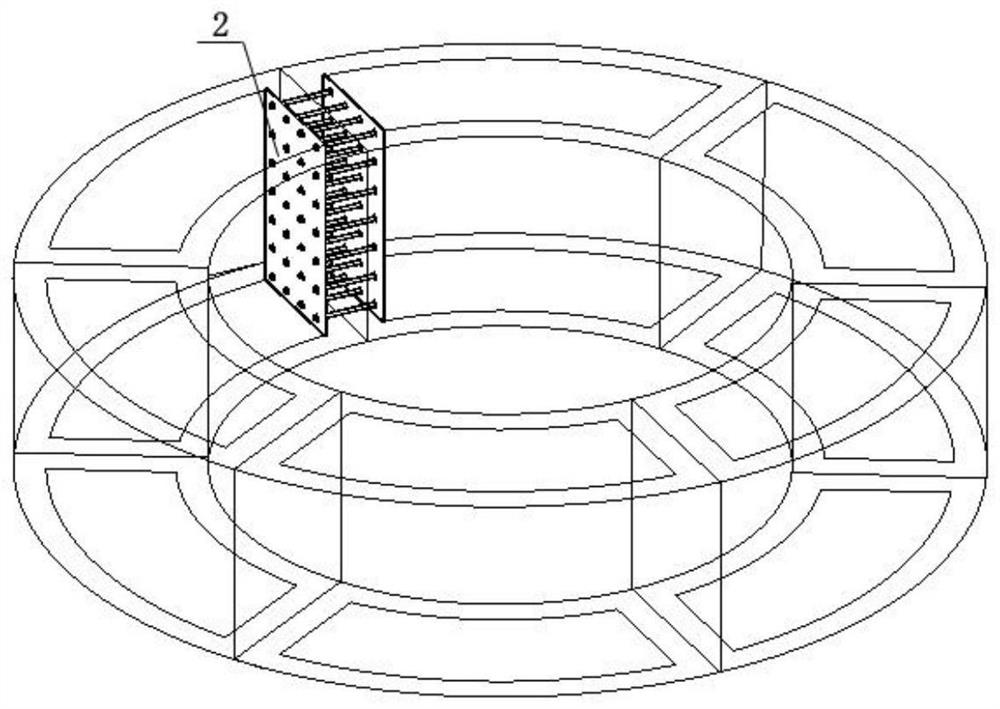

[0032] Such as figure 2 Shown is a perspective view of the hoop segment connection.

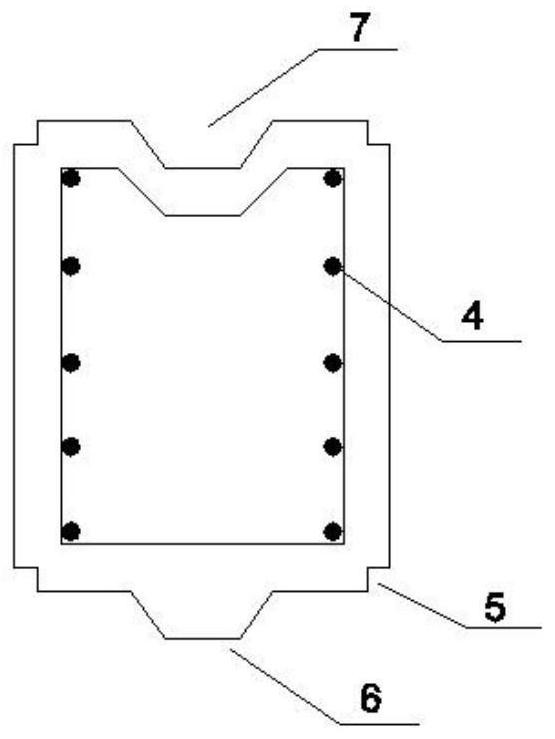

[0033] image 3 It is the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com