Recognition method for automatically detecting position of lifting lug

A recognition method and automatic detection technology, applied in image data processing, instrumentation, calculation, etc., can solve problems such as large amount of calculation, high cost, and difficulty in matching feature points, so as to improve work efficiency and reduce waste.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0050] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

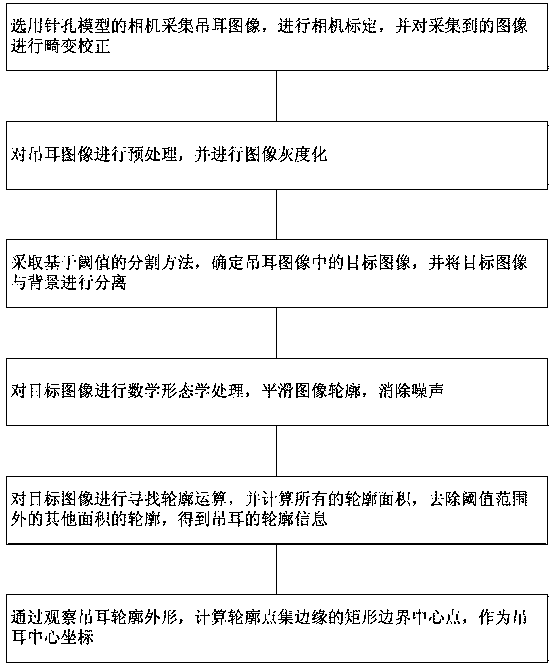

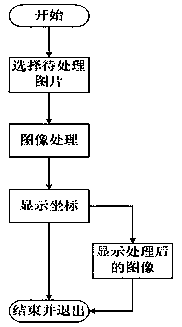

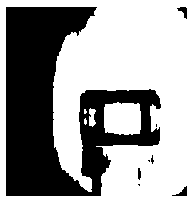

[0051] Such as figure 1 and figure 2 as shown, figure 1 It is a schematic flow chart of the identification method for automatically detecting the position of the lifting lug of the present invention, figure 2 It is a logical schematic diagram of the recognition method for automatically detecting the position of the lifting lug provided by the present invention. This method is identified by the following device for automatically identifying the hoisting position, which device includes (1) a cylinder with a diameter of 124 mm and a length of 62 mm for the pressure vessel; (2) a metal strip with a width of 10 mm for the lifting lug of the pressure vessel; (3) ) acA1300-60gm model camera produced by industrial camera BASLER; (4) computer.

[0052] Design the detection device for lifting lug position, including the design of hardware...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com