Non-standard automatic machining drilling device

A drilling device, non-standard technology, applied in boring/drilling, metal processing equipment, drilling/drilling equipment and other directions, can solve the problems of cooling, waste collection and reuse, etc., to improve the utilization rate and use longevity, the effect of avoiding damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

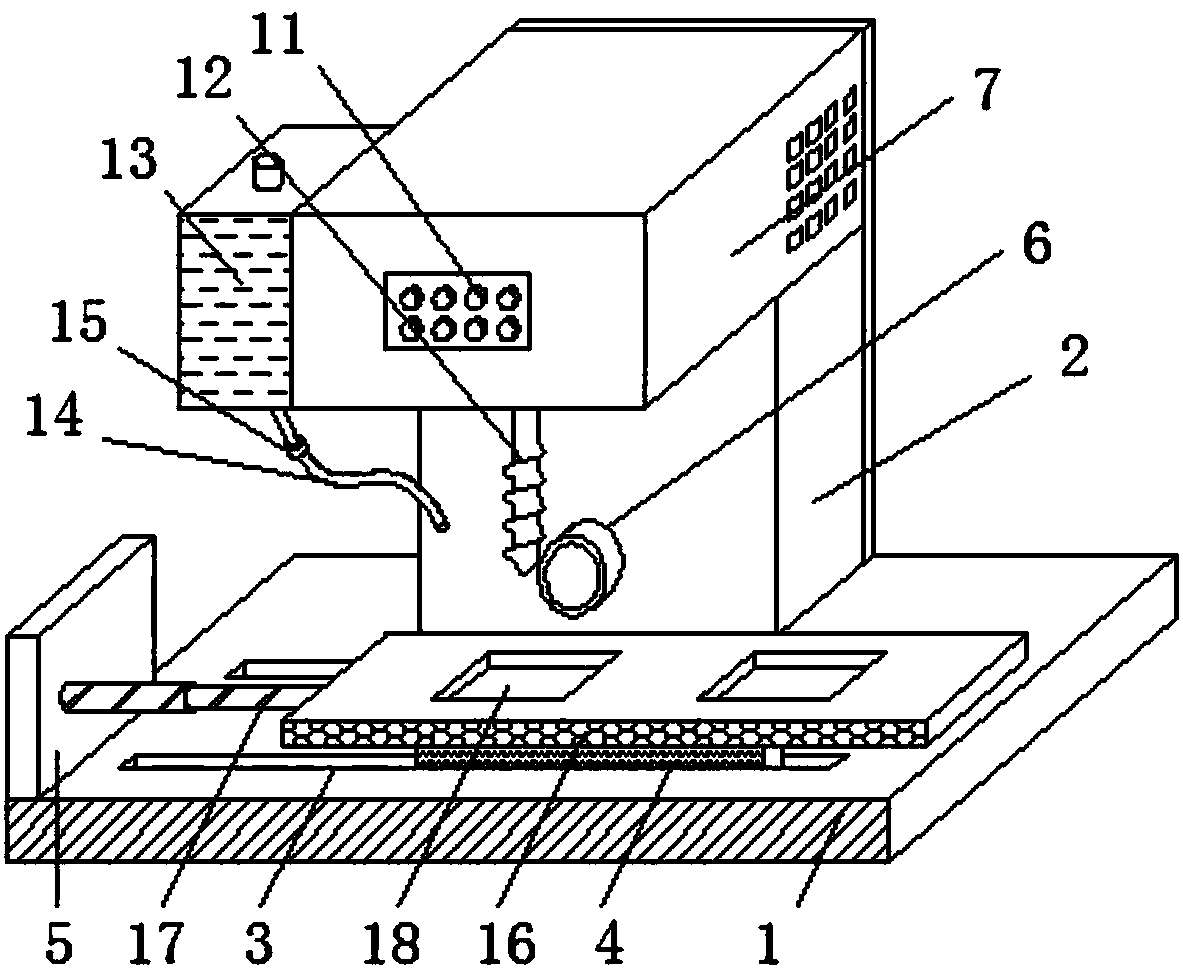

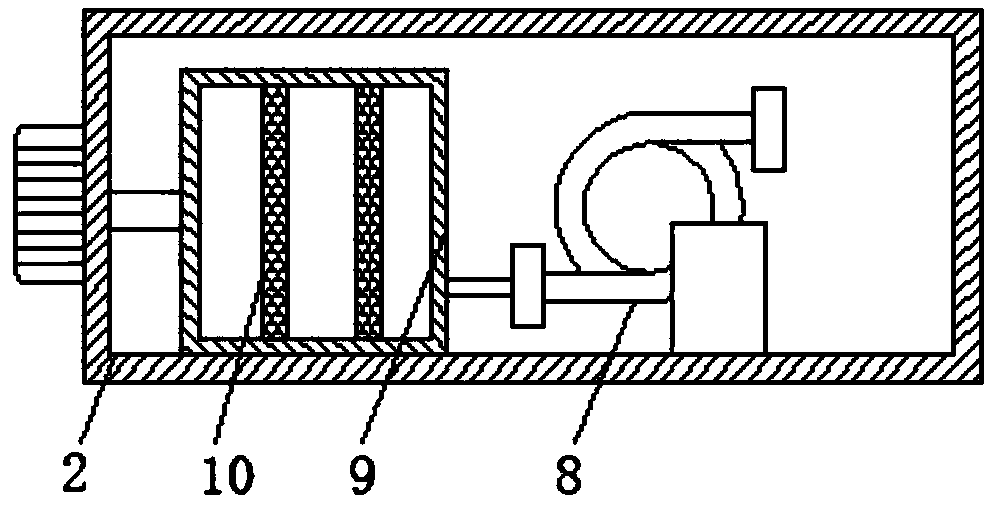

[0019] Example: refer to Figure 1-2 , the present invention provides a technical solution, a drilling device for non-standard automatic processing, including a base 1, the upper surface of the base 1 is fixedly installed with a vertical plate 2, and the upper surface of the base 1 is close to the position in front of the vertical plate 2. The slide rail 3, and the upper surface of the base 1 corresponds to the inside of the slide rail 3 with a slider 4 installed, the upper surface of the base 1 near the side of the slide rail 3 is installed with a fixed plate 5, and the front surface of the vertical plate 2 is provided with a dust collector Pipe 6, and a motor box 7 is installed above the vertical plate 2, a fan 8 is installed inside the vertical plate 2, a dust filter box 9 is installed on one side of the fan 8, a filter screen 10 is installed inside the dust filter box 9, and a motor box 7 The front surface of the motor box 7 is provided with a control switch 11, and the lo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com