A tooling structure that can realize stable clamping of any axial-flow blade

A blade and tooling technology, applied in the field of axial flow impeller machinery blade processing and inspection, can solve the problems of reducing the progress of inspection, a large number of tooling, waste of resources and costs, and achieve efficient design, shorten inspection cycles, and reduce inspection costs. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below with reference to the accompanying drawings and examples.

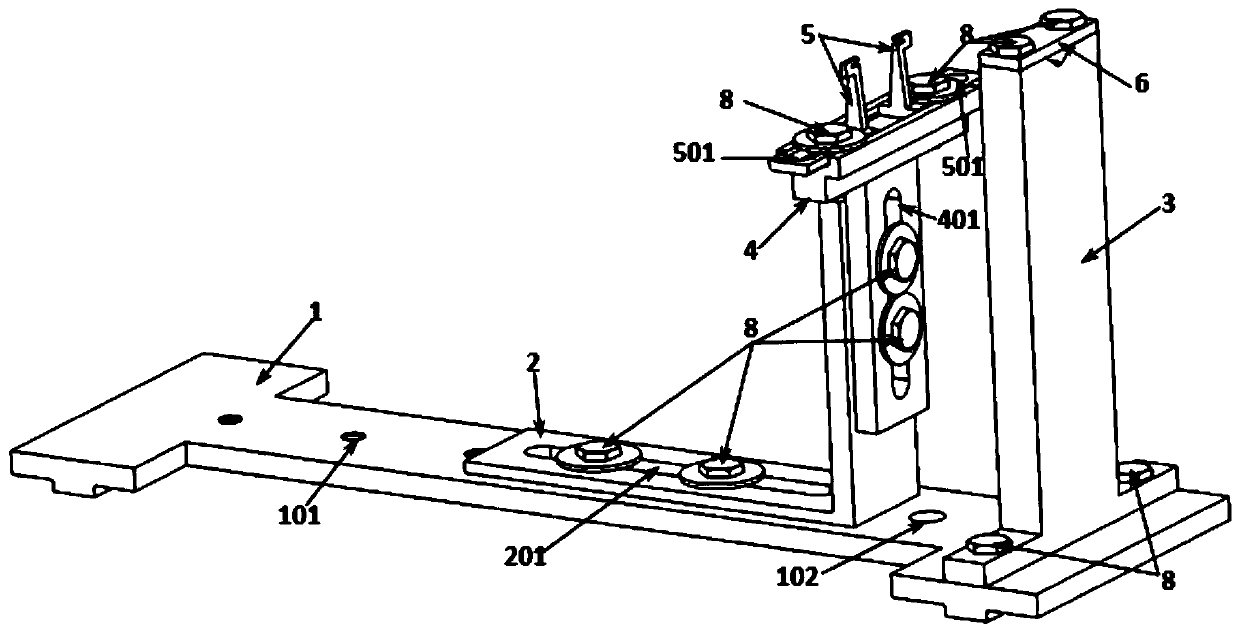

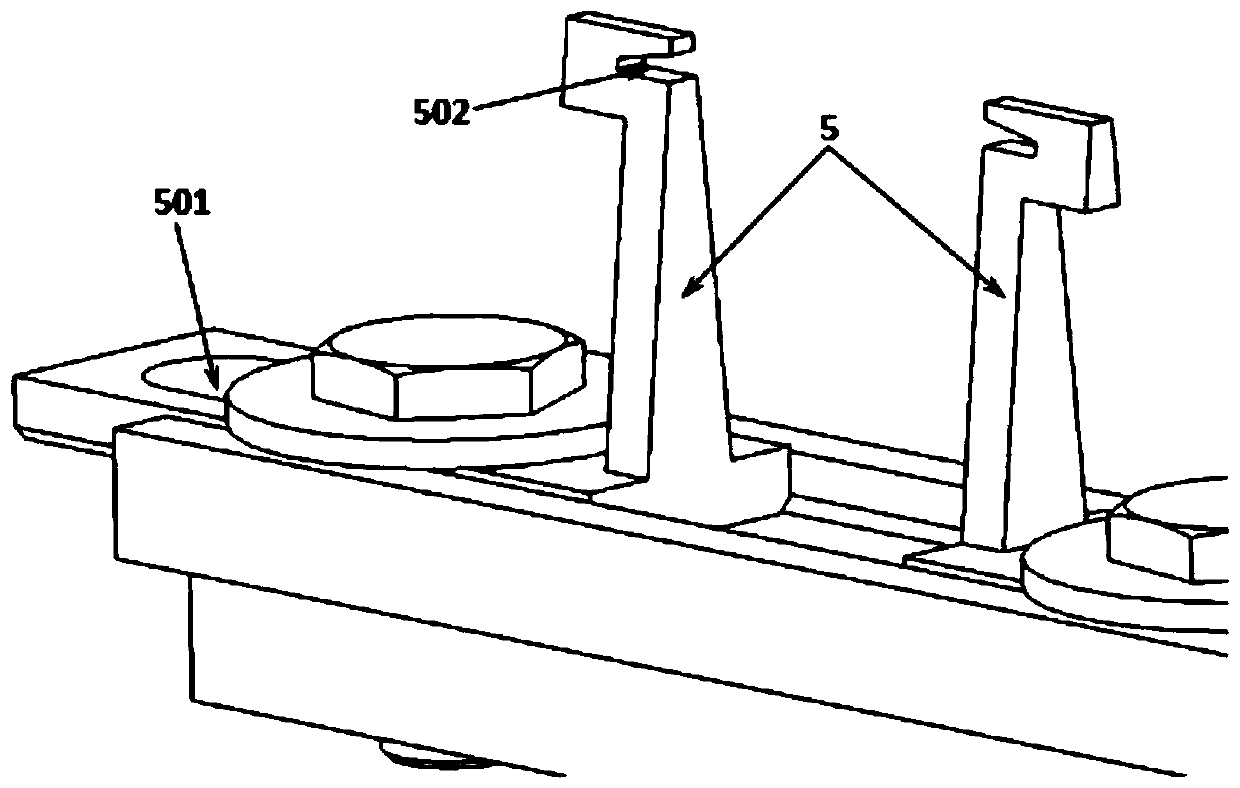

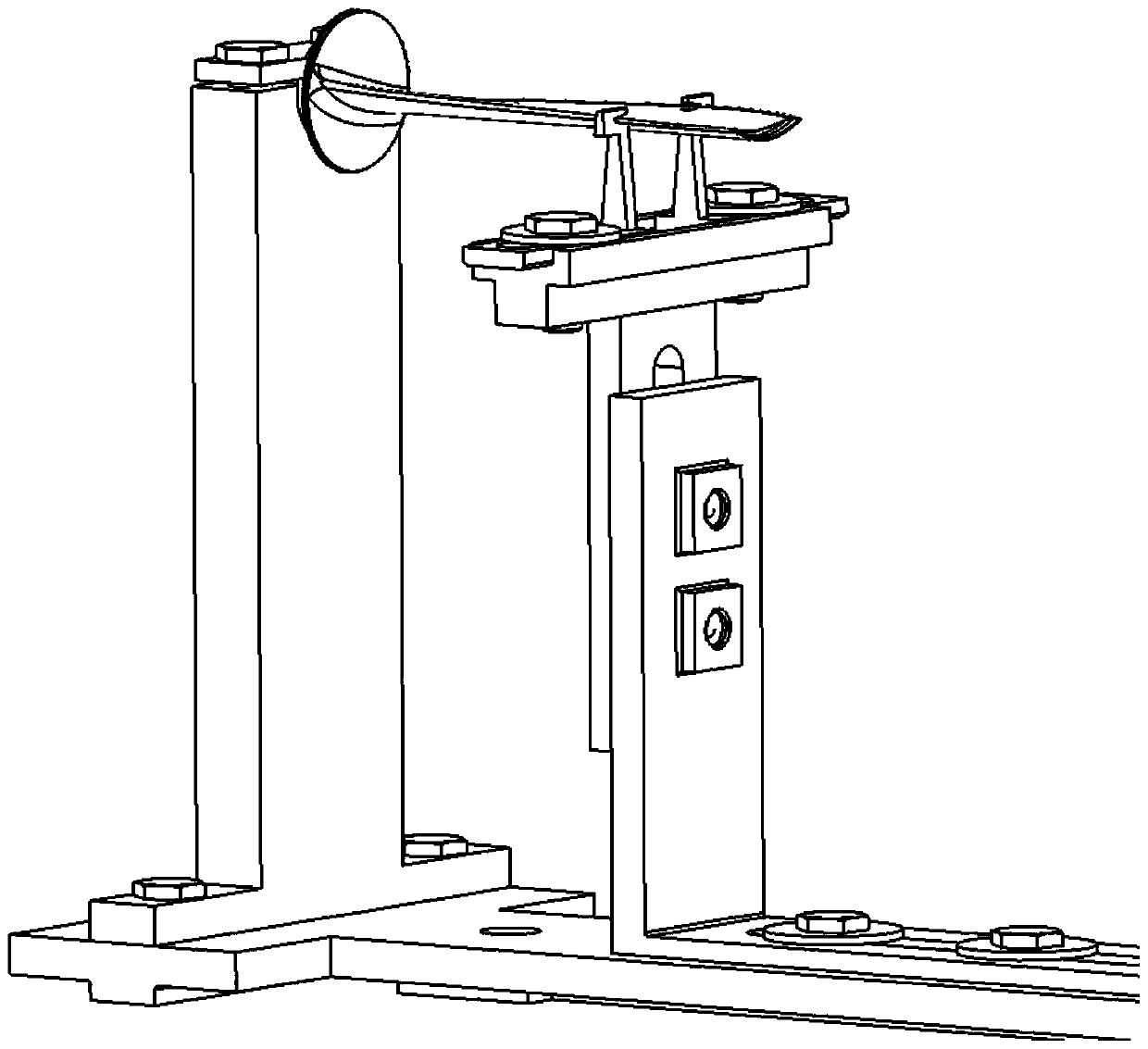

[0028] Such as figure 1 , 2 As shown, the tooling structure of the present invention that can realize the stable clamping of any axial-flow blade includes a base 1 and a movable bracket 2 and a fixed bracket 3 arranged on the base 1 . The base 1 is provided with a plurality of through holes 102, and the base 1 is fixed on the detection platform or the processing platform through the through holes 102 and the fasteners 8 arranged in the through holes 102, so as to ensure that the whole set of tooling will not be damaged during use. move. The bottom of the fixed bracket 3 is fixedly arranged on the base 1, and the top of the fixed bracket 3 is provided with a V-shaped groove designed and matched with a compression cover plate 6 to realize the fixing of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com