Method for preparing molybdenum carbide by gaseous reduction of molybdenum oxide

A technology of molybdenum carbide and molybdenum oxide, which is applied in the field of gaseous reduction of molybdenum oxide to prepare molybdenum carbide and gaseous reduction of molybdenum oxide to prepare ultra-fine molybdenum carbide, which can solve the problems of high cost and many impurities in the product

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

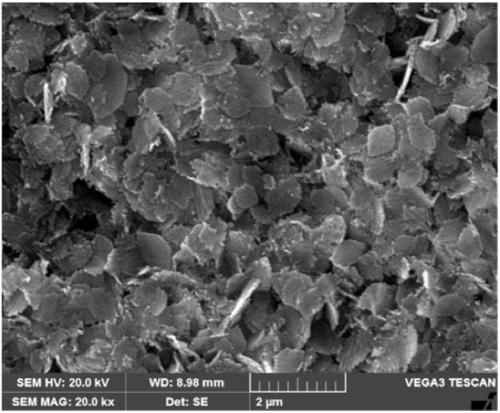

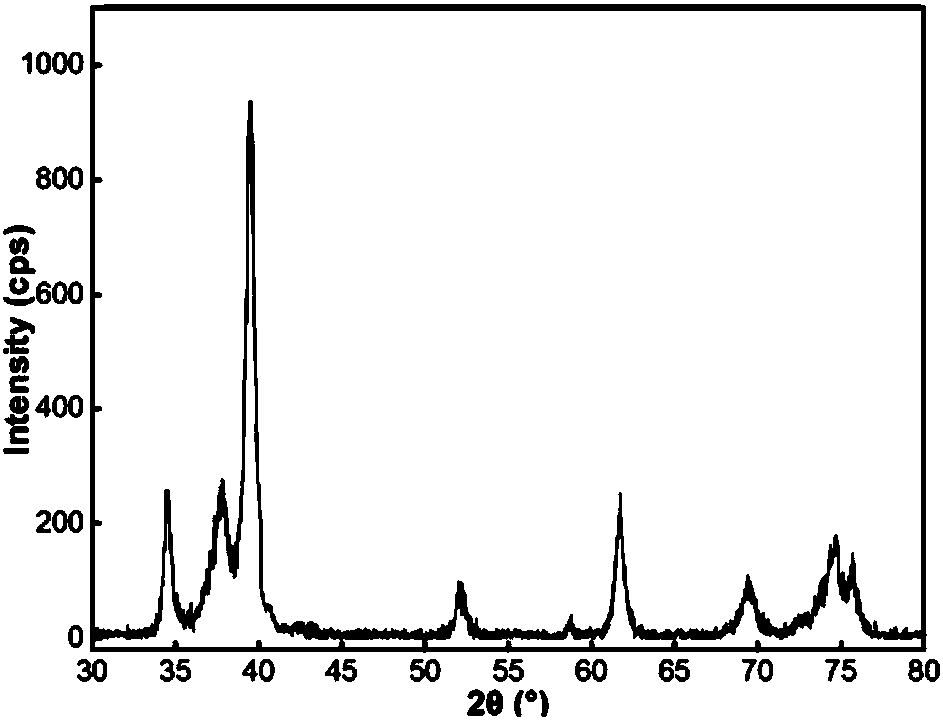

[0028] Using pure molybdenum trioxide (≥99.9%) powder as raw material, the steam generation temperature is controlled at 950°C, the reduction temperature is controlled at 1050°C, the molybdenum trioxide vapor is mixed with methane through nitrogen transport, and the molar ratio of reducing gas to volatile molybdenum trioxide is 3.5 , the mixed gas flows in the high temperature section for about 12s, and the solid product is obtained and cooled to room temperature under the protection of nitrogen. SEM detection shows that the product is a uniform nanosheet with a side length of 300-600nm and a thickness of 30-60nm, which is approximately hexagonal; XRD pattern shows that the product is pure molybdenum carbide, free carbon and uncarburized molybdenum oxide.

Embodiment 2

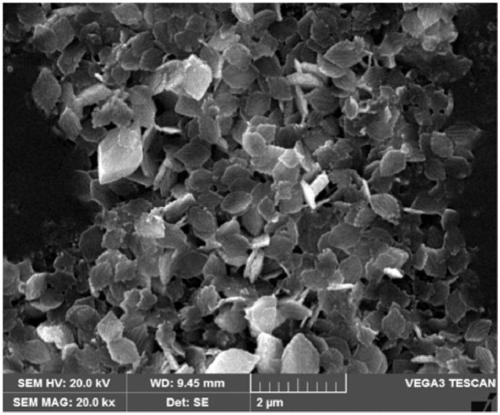

[0030] Using pure molybdenum trioxide (≥99.9%) powder as raw material, the steam generation temperature is controlled at 950°C, the reduction temperature is controlled at 1050°C, the molybdenum trioxide vapor is mixed with methane through nitrogen transport, and the molar ratio of reducing gas to volatile molybdenum trioxide is 3.5 , the flow time of the mixed gas in the high temperature section was extended to about 18s, and the solid product was obtained and cooled to room temperature under the protection of nitrogen. SEM inspection shows that most of the products are approximately hexagonal flakes with a side length of 300-600nm and a thickness of 50-150nm, but a small amount of coarse-grained layered molybdenum carbide also appears.

Embodiment 3

[0032] Using high-grade molybdenum calcined sand (60.47wt%) as raw material, the steam generation temperature is controlled at 1000°C, the reduction temperature is controlled at 1050°C, the molybdenum trioxide vapor is mixed with methane through nitrogen transport, and the molar ratio of reducing gas to volatile molybdenum trioxide is 3.5, the mixed gas flows in the high temperature section for about 12s, and the solid product is cooled to room temperature under the protection of nitrogen. SEM detection shows that the product is a uniform sheet with a side length of 300-600nm and a thickness of 50-150nm, which is approximately hexagonal; XRD pattern shows that the product is pure molybdenum carbide without free carbon and uncarburized molybdenum oxide.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com