Method for improving wettability of brazing filler metal based on surface modification of carbon-carbon composite

A carbon-carbon composite material and wettability technology, which is used in the field of improving the wettability of solder based on surface modification of carbon-carbon composite materials, and can solve problems such as reducing the joint connection performance and reliability, connecting interface cracks, and restricting applications. , to achieve the effect of improving joint connection performance, reducing residual stress and improving spreading

Inactive Publication Date: 2018-12-04

TIANJIN UNIV

View PDF4 Cites 2 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

However, due to the large difference in physical properties (thermal expansion coefficient and elastic modulus, etc.) between metal and carbon-carbon composite materials, the joint after metallurgical bonding will form a large residual stress during the cooling process, especially for the straight interface structure. It is very easy to produce cracks due to residual stress, which will greatly reduce the connection performance and reliability of the joint, and limit its application with metal connectors

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

[0022] The technical solutions of the present invention will be described in detail below in conjunction with specific embodiments.

[0023] The (three-dimensional) carbon-carbon composite material was purchased from Hunan Boyun New Material Co., Ltd., and its specific properties are shown in the following table:

[0024]

[0025]

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

Login to View More

Abstract

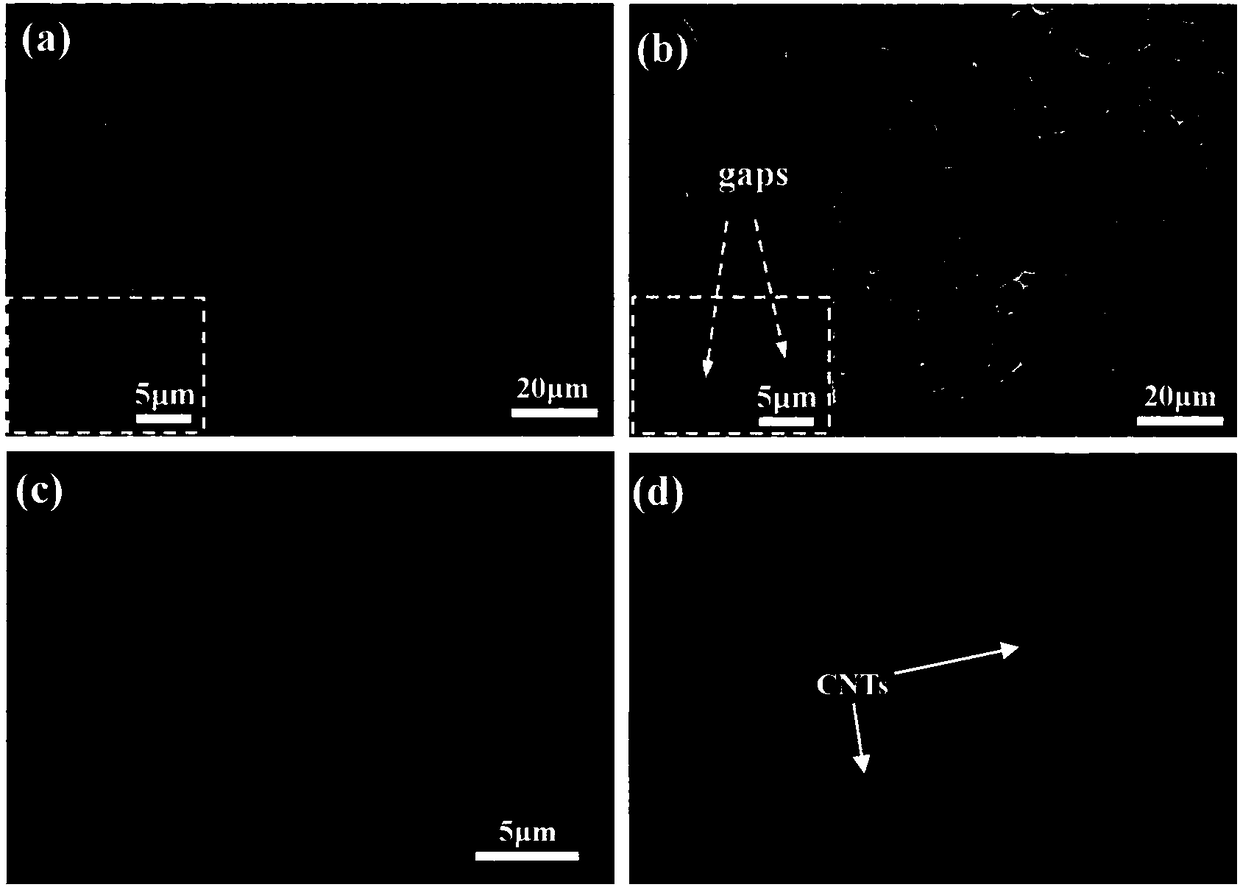

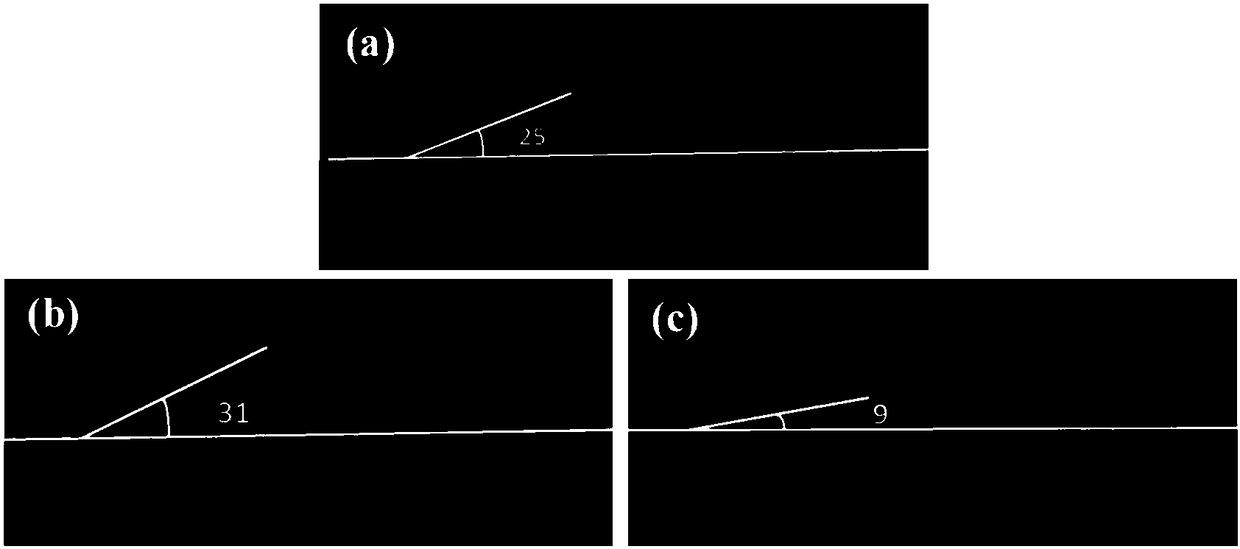

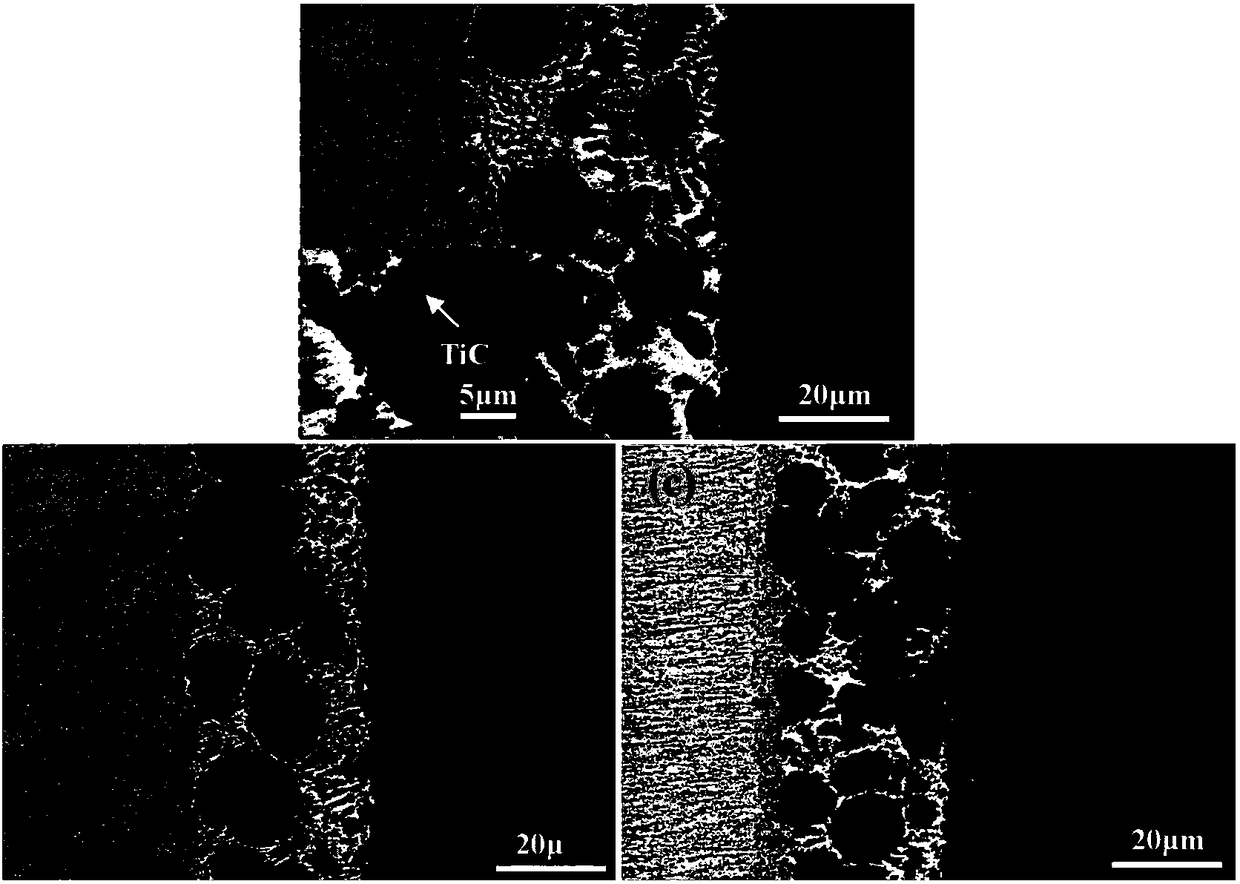

The invention discloses a method for improving the wettability of brazing filler metal based on surface modification of a carbon-carbon composite. Carbon nanotubes grow in situ in a hole formed afteroxidation pretreatment of the carbon-carbon composite and are used as a bridge to promote liquid brazing filler metal to be wetted and spread in a brazing process and improve the capacity of filling the hole. The carbon nanotubes grow on the surface of the carbon-carbon composite by selecting a chemical vapor deposition method, and the carbon-carbon composite is brazed or brazed together with metal by selecting the brazing filler metal capable of wetting the carbon-carbon composite after the carbon-carbon composite is subjected to surface modification. By using the method, the surface of the carbon-carbon composite which is not brazed is subjected to high-temperature oxidation, and CNTs grow on the surface of the carbon-carbon composite which is not brazed, an infiltration interface structure is formed between a brazinrg seam and the carbon-carbon composite, and the spreading and filling capacity of the liquid brazing filler metal is improved, so that the reaction of the brazing fillermetal and the carbon-carbon composite is more sufficient, and the method has important significance in reducing residual stresses in joints and improving the connection performance of the joints.

Description

technical field [0001] The invention relates to a method for improving the brazing connection performance of itself or metal by modifying the connection surface of carbon-carbon composite materials during the brazing process. More specifically, it relates to a high-temperature oxidation treatment on the surface of carbon-carbon composites to form an impregnated interface in the brazed joint to increase the connection area and form a pinning effect, and to form a high-temperature oxidation treatment of carbon-carbon by chemical vapor deposition. A method of growing carbon nanotubes (CNTs) on the surface of composite materials to improve the wettability of liquid solder to the surface of composite materials. At the same time, CNTs react in situ during the brazing process to form compounds with low thermal expansion coefficients in the interface connection area, which further relieves residual stress and improves joint connection performance. Background technique [0002] Carb...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C04B37/02C04B41/85

CPCC04B37/026C04B41/009C04B41/5001C04B41/85C04B2237/125C04B2237/126C04B2237/127C04B2237/385C04B2237/403C04B2237/55C04B35/83C04B41/4531C04B41/5346

Inventor 杨振文王春雷王颖林佳美韩英王东坡

Owner TIANJIN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com