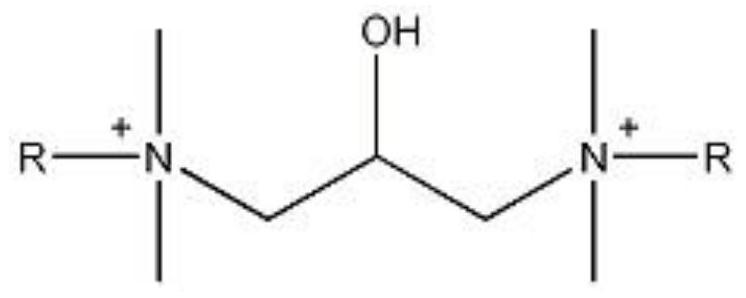

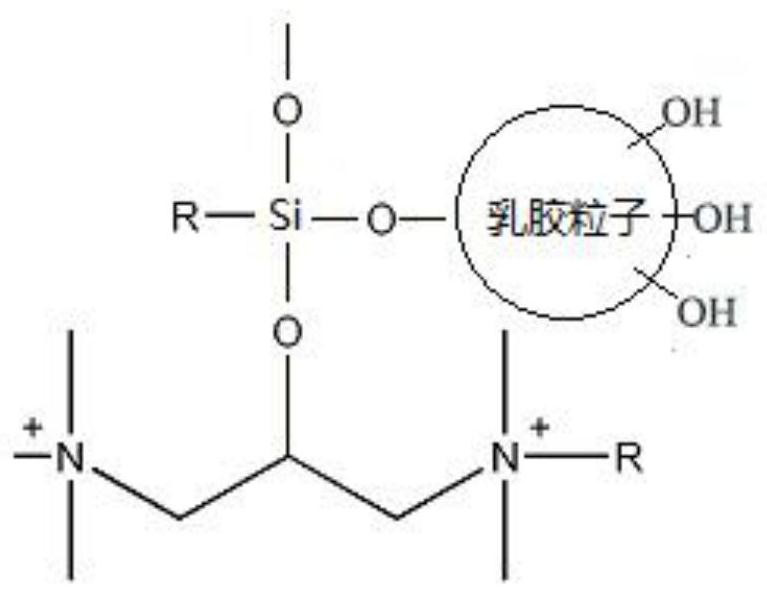

A kind of preparation method of self-extinction matte emulsion with gemini structure

A self-extinction, emulsion technology, applied in the field of exterior wall building materials and coatings, can solve the problems of settlement, low gloss, limited addition, etc., and achieve the effect of broad application prospects, high stability and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] (1) Weigh 20.6g of dodecyl tertiary amine and 10g of hydrochloric acid to fully mix, then add 25g of ethanol and 20.6g of dodecyl tertiary amine, after stirring evenly, drop 5g of epichlorohydrin in 1h, after titration, at 60 Continue to stir and react at ℃ for 6h to obtain a mixed liquid containing hydroxyl gemini surfactant.

[0021] (2) Weigh 190g of water and add it to (1), use the AMP-95 adjustment system to adjust the pH of the system to 8-10, add 30g of methyltrimethoxysilane, stir well, add 700g of hydroxyacrylic acid emulsion, and continue at room temperature The reaction was stirred for 1 hour, and after the reaction was completed, a self-dulling matte emulsion was obtained.

Embodiment 2

[0023] (1) Weigh 32.4g hexadecyl tertiary amine and 12g hydrochloric acid and fully mix, then add 35g ethylene glycol and 32.4g dodecyl tertiary amine, after stirring evenly, drop 5g epichlorohydrin in 1h, after titration, in The reaction was continued at 65°C for 6 hours to obtain a mixed liquid containing hydroxyl gemini surfactants.

[0024] (2) Weigh 150g of water and add it to (1), use the AMP-95 adjustment system to adjust the pH of the system to 8-10, add 45g of phenyltrimethoxysilane, stir well, add 700g of hydroxyacrylic acid emulsion, and continue at room temperature The reaction was stirred for 1 hour, and after the reaction was completed, a self-dulling matte emulsion was obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com