Energy gradient utilization multi-energy complementary heat supply system and heat supply method

A heat supply system and energy technology, applied in multi-energy complementary heat supply systems and heat supply fields, can solve the problems of increasing the amount of supplementary heat from high-quality heat sources, incomplete matching, and increased use of high-quality heat degradation, so as to benefit the power grid Peak shaving, reducing the average temperature difference between cold and heat sources, and improving the performance of heat pumps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

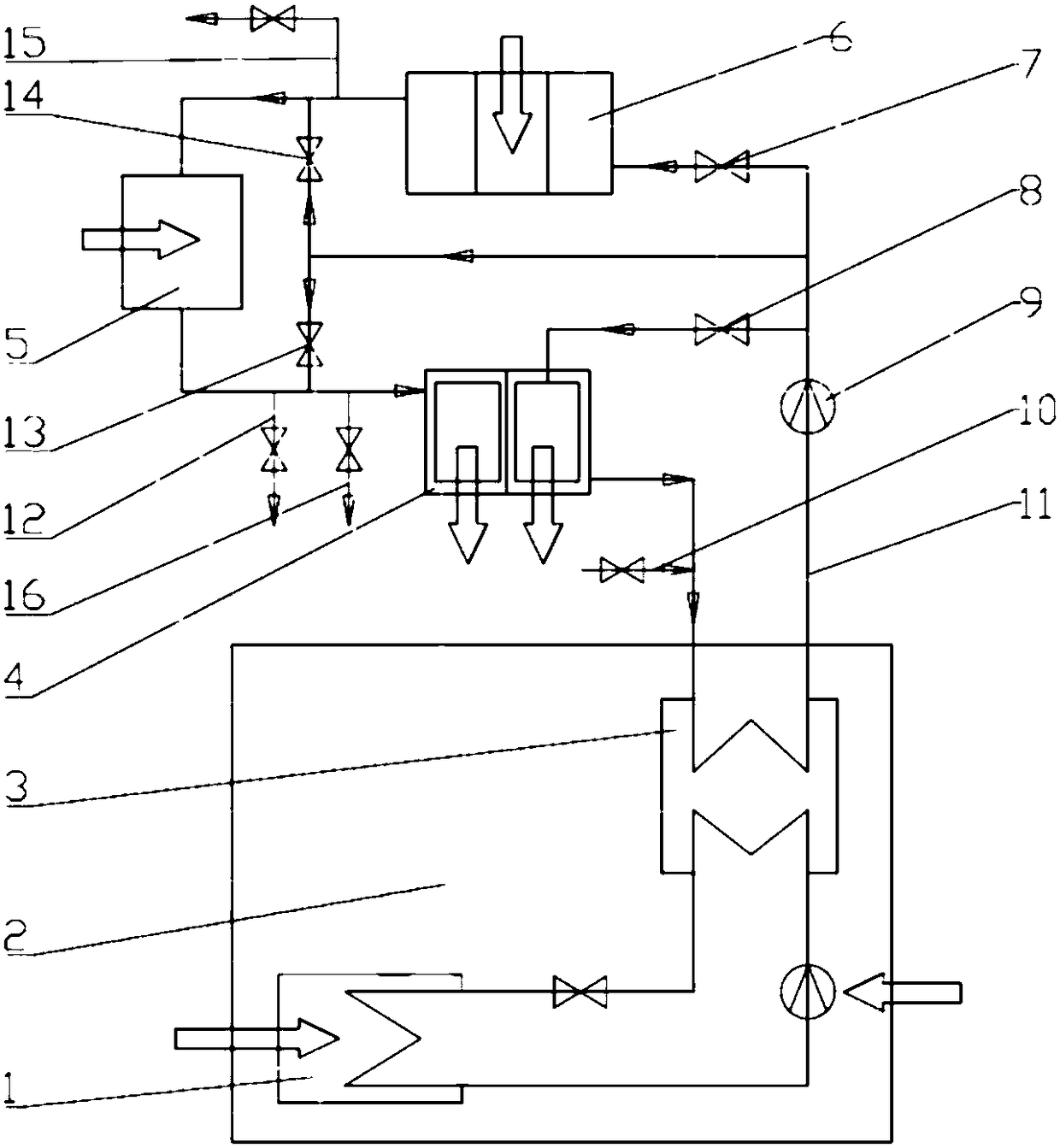

[0046] Such as figure 1 As shown, a multi-energy complementary heating system utilizing cascade energy, the heating system includes a heat pump 2, a low-temperature heater 6, a high-temperature heater 5, a heat user 4, a circulation pump 9 and a circulation pipeline 11;

[0047] The heat pump 2 includes a heat pump evaporator 1 and a heat pump condenser 3; the low-temperature side inlet and outlet of the heat pump condenser 3 are connected to a circulation pipeline 11; the circulation pipeline 11 is sequentially provided with a circulation pump 9, Low temperature heater 6, high temperature heater 5 and heat user 4.

[0048] The heating system is provided with a heater bypass pipeline, one end of the heater bypass pipeline is connected between the heat user 4 and the high-temperature heater 5 on the circulation pipeline 11, and the other end is connected to the circulation pipe Between the low-temperature heater 6 and the circulating pump 9 on the pipeline 11, a rear diverter ...

Embodiment 2

[0062] The heating method based on embodiment 1 system comprises the following steps:

[0063] High-quality energy drives the heat pump 2 to perform a thermodynamic cycle. The heat pump evaporator 1 absorbs heat from the lowest temperature heat source, and then heats up through the heat pump circulation system, so that the absorbed heat and the high-quality energy input by the heat pump enter the heat pump together with the working fluid of the heat pump circulation system On the high temperature side of the condenser 3, in the heat pump condenser 3, the working fluid of the heat pump circulation system transfers the heat to the circulating medium (such as circulating water) from the circulation line 11 on the low temperature side of the heat pump condenser 3;

[0064] The circulating medium on the low-temperature side of the heat pump condenser 3 is driven by the circulating pump 9, heated by the low-temperature heat source through the low-temperature heater 6, and then enters...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com