Soluble dietary fiber, lactating sow feed, and preparation method and applications of lactating sow feed

A technology of dietary fiber and lactating sows, applied in the field of pig feed, can solve the problems of low fiber content, mycotoxin pollution, affecting fiber application, etc., and achieve the effect of high nutrition and increased feed intake

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

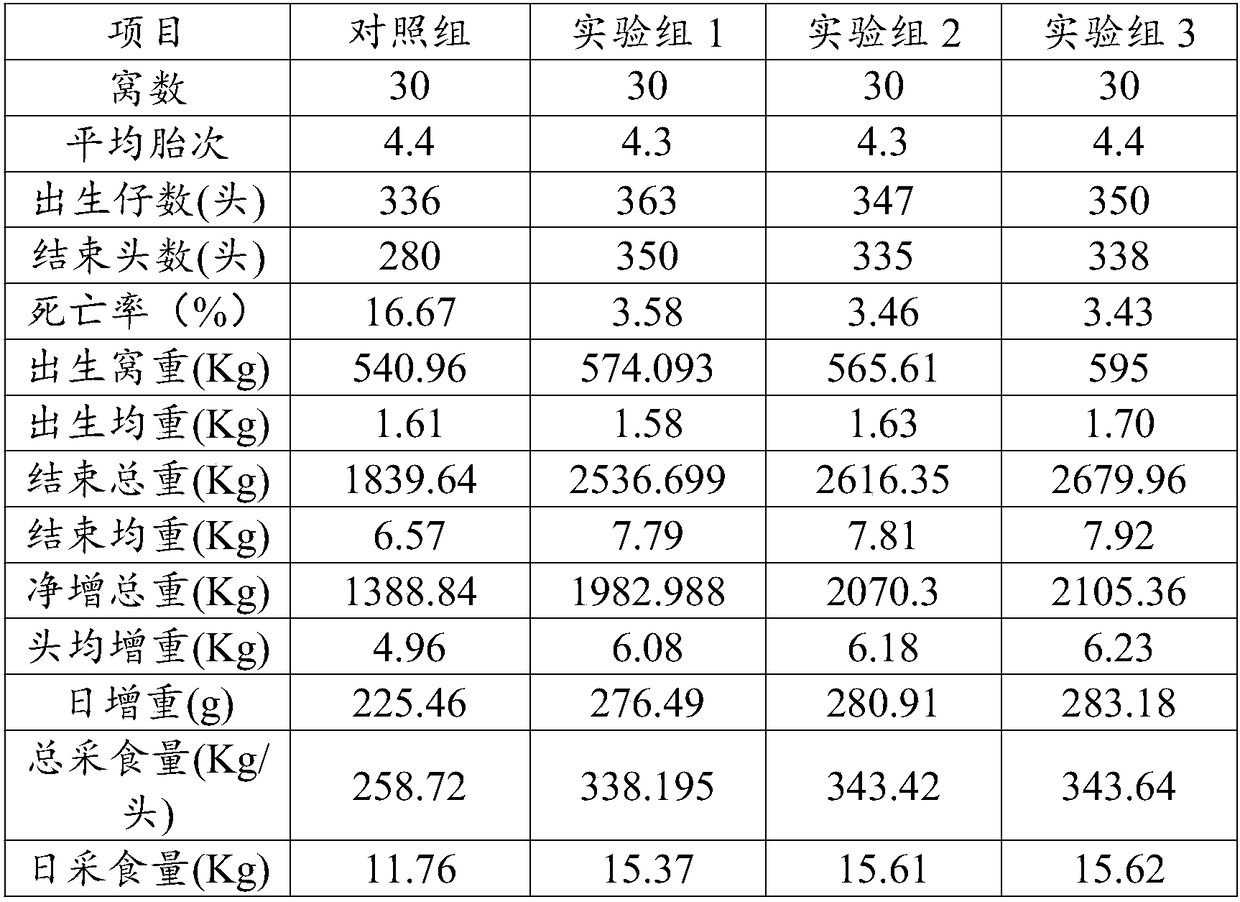

Examples

Embodiment 1

[0048] Take by weighing sweet potato vine powder 100Kg, glucose 3Kg, nutrient salt 0.5Kg, water 200Kg and lactic acid bacteria (the live bacteria concentration of lactic acid bacteria is 1.0 * 10 6 CFU / g) 10Kg was stirred at 2000r / min for 3min, and then the mixture was anaerobically fermented at 25°C for 24h to obtain a lactic acid bacteria fermentation broth. Mix the obtained lactic acid bacteria fermentation broth with citric acid (the mass ratio of sweet potato vine powder and citric acid is 20:1), obtain the citric acid mixed solution, adjust the pH value to 7, mix it with Aspergillus niger, and ferment it at 28°C for 72h to obtain Aspergillus niger fermentation broth. Mix the obtained Aspergillus niger fermentation liquid with cellulase, pectinase and protease in a mass ratio of 100:0.1:0.05:0.005, carry out enzymolysis at 35°C for 12 hours, filter, collect the filtrate and filter residue respectively, and obtain the filtrate For soluble dietary fiber.

[0049] Weigh 13...

Embodiment 2

[0051] Take sweet potato vine powder 100Kg, glucose 5Kg, nutrient salt 0.2Kg, water 400Kg and lactic acid bacteria (the live bacteria concentration of lactic acid bacteria is 1.0 * 10 9 CFU / g) 5Kg was stirred at 2000r / min for 3min, and the mixture was anaerobically fermented at 30°C for 18h to obtain a lactic acid bacteria fermentation broth. Mix the obtained lactic acid bacteria fermentation broth with citric acid (the mass ratio of sweet potato vine powder and citric acid is 100:1), obtain the citric acid mixed solution, adjust the pH value to 6, mix it with Aspergillus niger, and ferment it at 32°C for 36h to obtain Aspergillus niger fermentation broth. Mix the obtained Aspergillus niger fermentation liquid with cellulase, pectinase and protease in a mass ratio of 100:0.5:0.01:0.05, carry out enzymolysis at 50°C for 8 hours, filter, collect the filtrate and filter residue respectively, and obtain the filtrate For soluble dietary fiber.

[0052] Weigh 140Kg of soluble fibe...

Embodiment 3

[0054] Take sweet potato vine powder 100Kg, glucose 4Kg, nutrient salt 0.35Kg, water 300Kg and lactic acid bacteria (the live bacteria concentration of lactic acid bacteria is 1.0 * 10 8 CFU / g) 8Kg was stirred at a speed of 2000r / min for 3min, and the mixture was anaerobically fermented at 28°C for 20h to obtain a lactic acid bacteria fermentation broth. Mix the obtained lactic acid bacteria fermentation liquid with citric acid (the mass ratio of sweet potato vine powder and citric acid is 100:3), obtain the citric acid mixed liquid, adjust the pH value to 6.5, mix it with Aspergillus niger, and ferment it at 30°C for 55h to obtain Aspergillus niger fermentation broth. Mix the obtained Aspergillus niger fermentation broth with cellulase, pectinase and protease in a mass ratio of 100:0.3:0.03:0.03, carry out enzymolysis at 42°C for 10 hours, filter, collect the filtrate and filter residue respectively, and obtain the filtrate For soluble dietary fiber.

[0055] Weigh 135Kg of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com