Soluble dietary fiber, lactating sow feed as well as preparation method and application of lactating sow feed

A technology of dietary fiber and lactating sows, applied in the field of pig feed, can solve the problems of low proportion of fermentable fiber, restricting the development of pig industry, and mycotoxin pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

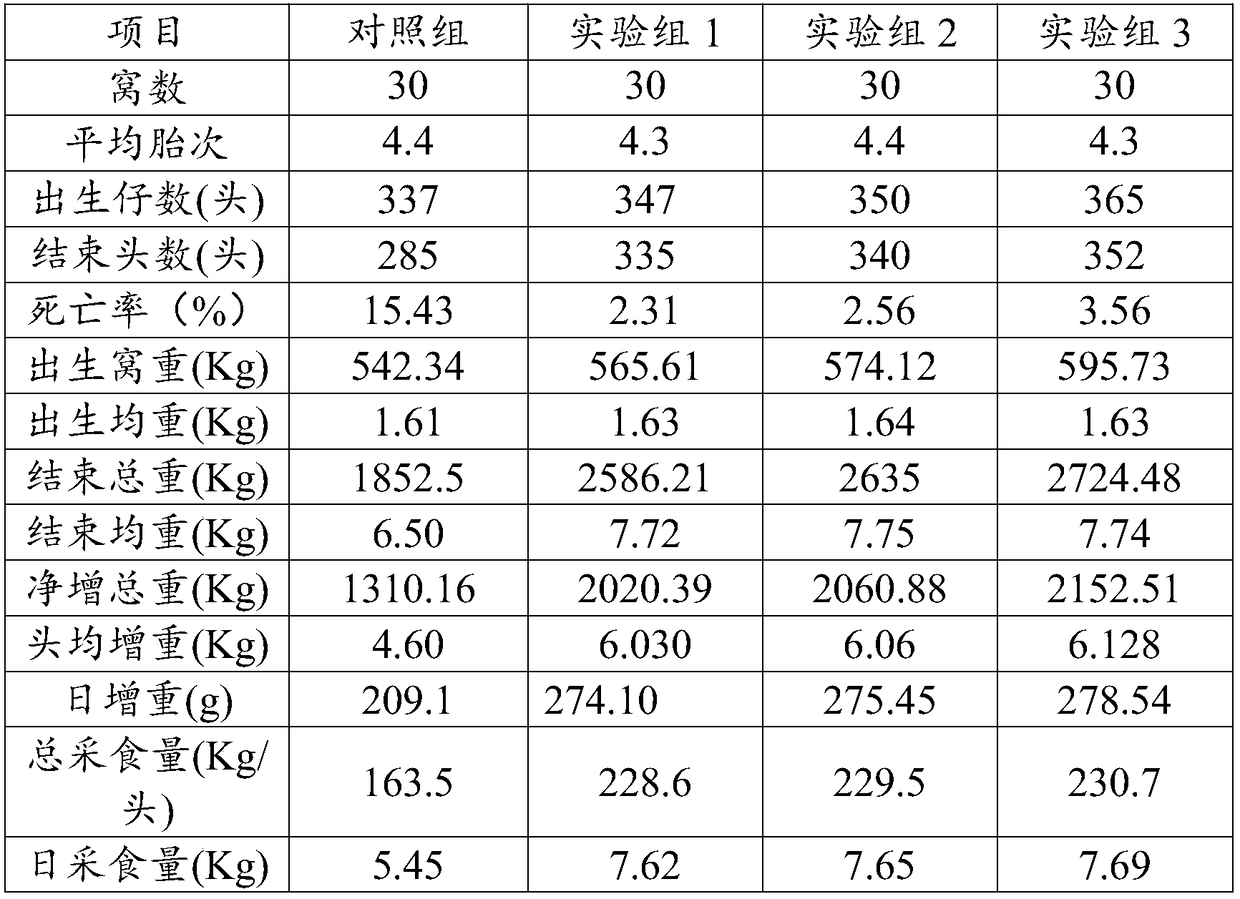

Examples

Embodiment 1

[0047] Weigh 100Kg of alfalfa powder, 20Kg of corn flour and 16Kg of water and stir at a speed of 1000r / min for 10min, then puff the mixture at 180°C to obtain 114Kg of puffed alfalfa. Mix puffed alfalfa with 342Kg water, stir at 2000r / min for 3min, add 684g amylase and 912g pectinase, and perform enzymolysis at 70°C for 3h to obtain the first enzymolysis solution. 456 g of cellulase and 45.6 g of protease were added to the first enzymatic hydrolysis solution, and the enzymatic hydrolysis was carried out at 40° C. for 10 hours to obtain the second enzymatic hydrolysis solution. The second enzymolysis solution is separated from solid and liquid, and the filtrate and filter residue are collected respectively, and the obtained filtrate is soluble dietary fiber. The soluble dietary fiber is evaporated and concentrated at 50° C., and the mass of solids in the concentrated solution obtained after concentration is preferably 60% of the total mass of the concentrated solution. Weigh ...

Embodiment 2

[0049] Weigh 100Kg of alfalfa powder, 40Kg of corn flour and 8Kg of water and stir at a speed of 2000r / min for 3min, then puff the mixture at 150°C to obtain 135Kg of puffed alfalfa. Mix puffed alfalfa with 675Kg water, stir at 1000r / min for 10min, add 540g amylase and 81g pectinase, and perform enzymolysis at 60°C for 5h to obtain the first enzymolysis solution. 810 g of cellulase and 40.5 g of protease were added to the first enzymolysis solution, and the enzymolysis was carried out at 50° C. for 5 hours to obtain the second enzymolysis solution. The second enzymolysis solution is separated from solid and liquid, and the filtrate and filter residue are collected respectively, and the obtained filtrate is soluble dietary fiber. The soluble dietary fiber is evaporated and concentrated at 60° C., and the mass of solids in the concentrated solution obtained after concentration is preferably 70% of the total mass of the concentrated solution.

[0050] Weigh 190Kg of soluble fibe...

Embodiment 3

[0052] Weigh 100Kg of alfalfa powder, 30Kg of corn flour and 12Kg of water and stir at a speed of 1500r / min for 5min, then puff the mixture at 170°C to obtain 124Kg of puffed alfalfa. Mix puffed alfalfa with 500Kg water, stir at 1500r / min for 5min, add 620g amylase and 62g pectinase, and perform enzymolysis at 65°C for 4h to obtain the first enzymolysis solution. Add 3.12Kg of cellulase and 50g of protease to the first enzymolysis solution, and perform enzymolysis at 45° C. for 8 hours to obtain the second enzymolysis solution. The second enzymolysis solution is separated from solid and liquid, and the filtrate and filter residue are collected respectively, and the obtained filtrate is soluble dietary fiber. The soluble dietary fiber is evaporated and concentrated at 55° C., and the mass of solids in the concentrated solution obtained after concentration is preferably 55% of the total mass of the concentrated solution.

[0053] Weigh 190Kg of soluble fiber concentrate, 88Kg o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com