Exhaust system for industrial waste gas purification equipment

A purification device and technology for industrial waste gas, applied in gas treatment, chemical instruments and methods, use of liquid separation agents, etc., can solve the problems of variable nature, low level, and complex composition of industrial waste gas, so as to achieve efficient recycling and improve purification. effect of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0033] Specific embodiment one:

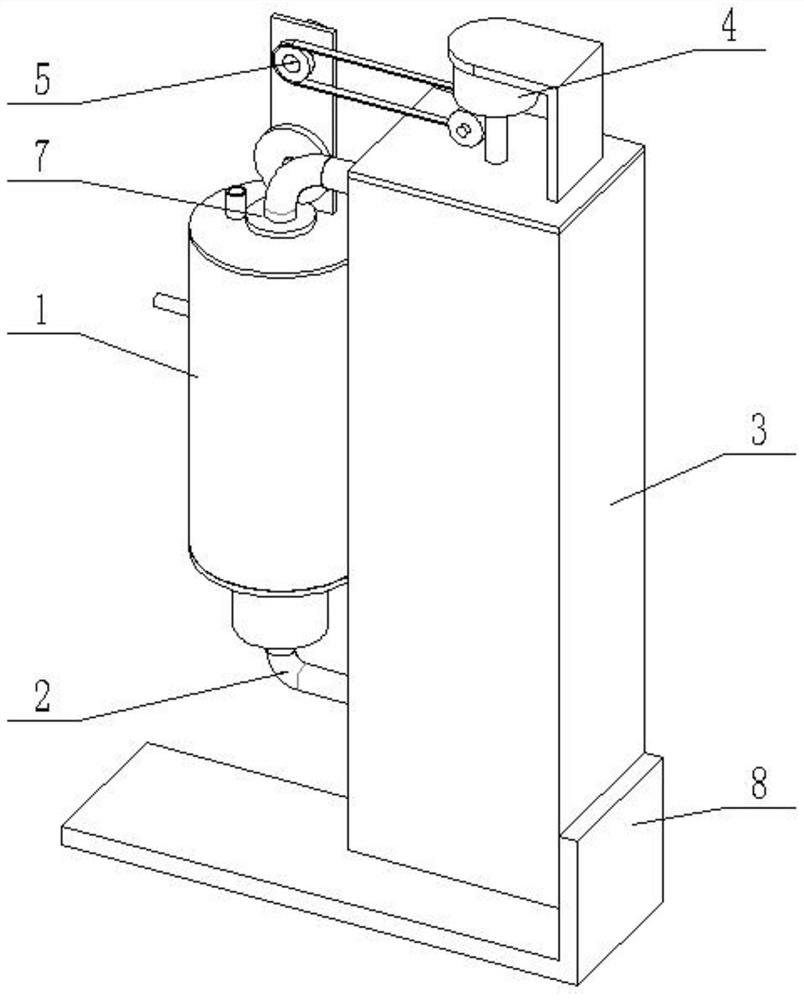

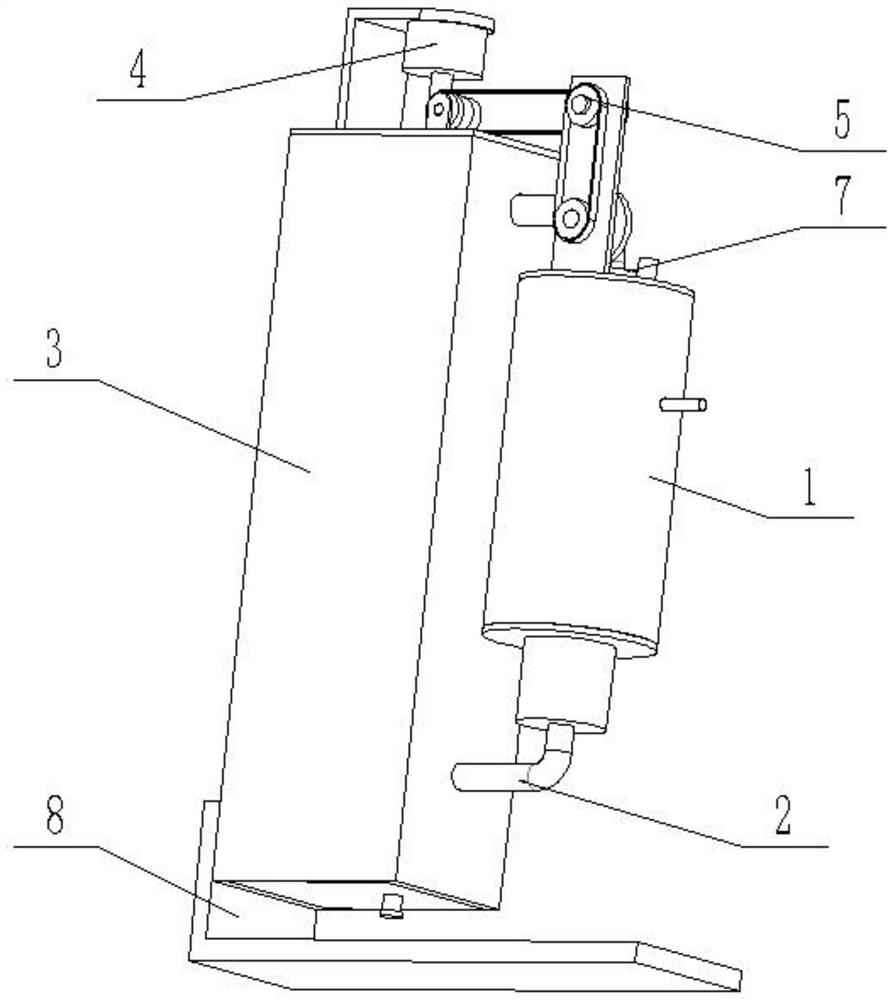

[0034] Such as Figure 1-15 As shown, the exhaust system for an industrial waste gas purification device includes a spray box 1, a circulating pipe 2, a circulating water tank 3, a circulating controller 4, a transmission wheel 5, a water return 6, a spray 7 and a support seat 8. The lower end of the spray box 1 is connected to and connected to the circulating pipe 2, and the lower end of the circulating pipe 2 is inserted into the lower end of the circulating water tank 3; the upper end of the circulating water tank 3 is connected to and connected to the upper end of the sprayer 7, and the lower end of the sprayer 7 is inserted To the inside of the spray box 1; the circulation controller 4 is fixedly connected to the circulating water tank 3, and the circulation controller 4 is connected to the sprayer 7 through the transmission wheel 5; the circulating water tank 3 is fixedly connected to the support base 8; The circulation controller 4 is dri...

Example Embodiment

[0035] Specific implementation manner two:

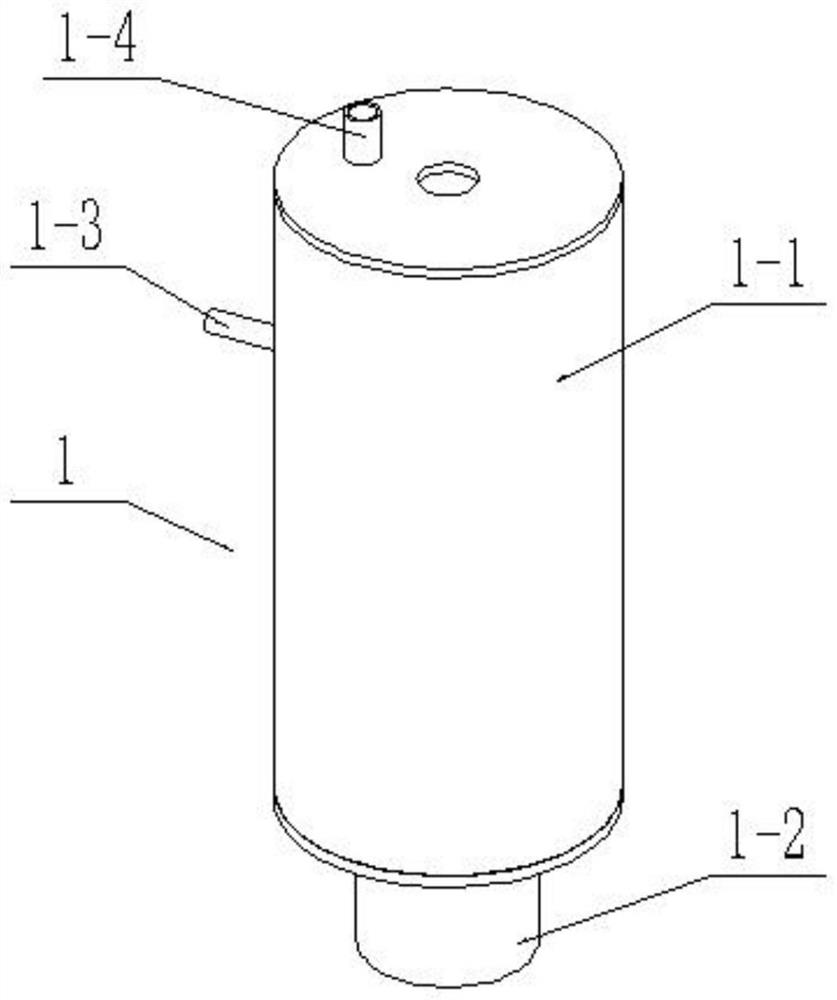

[0036] Such as Figure 1-15 As shown, the spray box 1 includes an upper box body 1-1, a lower box body 1-2, a right-angle intake pipe 1-3, an exhaust pipe 1-4, a lifting water storage tank 1-5, and a spring rod 1-6 , Tension spring 1-7, drainage inner pipe 1-8, drainage outer pipe 1-9 and movable pipe cover 1-10; the lower end of the upper box body 1-1 is fixedly connected with the lower box body 1-2; The top surface of the upper box body 1-1 is fixedly connected and connected to the exhaust pipe 1-4, and the upper end of the outer side of the upper box body 1-1 is fixedly connected and connected to the right-angle intake pipe 1-3 and the lower end of the right-angle intake pipe 1-3 The nozzle is inserted into the lower end inside the upper box body 1-1, and the lower end nozzle of the right-angle air intake pipe 1-3 is arranged on the inner side of the lifting water storage tank 1-5; the lifting water storage tank 1-5 is connected to...

Example Embodiment

[0037] Specific implementation manner three:

[0038] Such as Figure 1-15 As shown, the circulating pipe 2 includes a curved water delivery pipe 2-1, a preliminary filter cartridge 2-2, an outer gear ring 2-3, a trash pipe 2-4, and a pipe cover 2-5; the curved water delivery pipe 2- One end of 1 is fixedly connected and connected to the middle of the bottom end of the lower tank 1-2; the middle end of the curved water pipe 2-1 is sealed and fixedly connected to the outer surface of the circulating water tank 3, and the other end of the curved water pipe 2-1 passes The seated bearing is connected to the middle of the top end of the preliminary filter cartridge 2-2, and the outer surface of the preliminary filter cartridge 2-2 is fixedly connected with the outer gear ring 2-3; the middle of the bottom end of the preliminary filter cartridge 2-2 is fixedly connected to remove impurities Tube 2-4; the bottom end of the trash pipe 2-4 is connected to the pipe cover 2-5 through a thr...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap