Induction heating leveling integral structure

A technology of induction heating and overall structure, applied in induction heating, induction heating control, metal processing equipment, etc., can solve problems such as stability of leveling effect, poor consistency, poor safety of acetylene and liquefied petroleum gas, toxic gas and smoke pollution, etc. , to achieve the effect of easy promotion, wide operation range and stable heating process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The following examples can enable those skilled in the art to understand the present invention more comprehensively, but the present invention is not limited to the scope of the described examples.

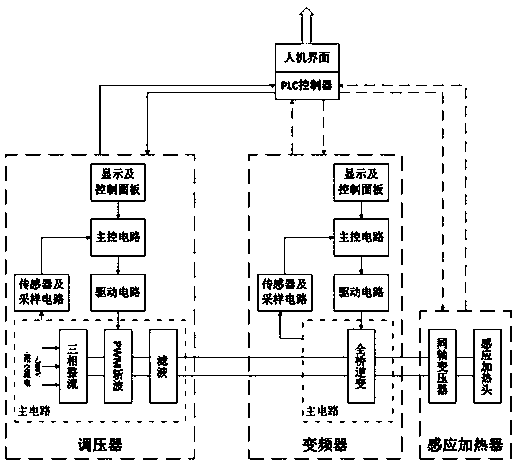

[0038] Such as Figure 1 to Figure 11 The overall structure of induction heating leveling shown includes a control system 1 , a water cooling system 2 and an execution system 3 .

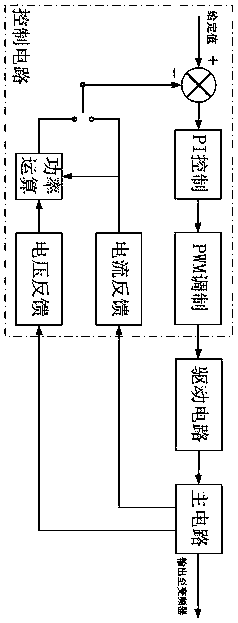

[0039] Control system 1 comprises main circuit 11, drive circuit 12 and control circuit 13, described main circuit 11, drive circuit 12 and control circuit 13 constitute a complete closed-loop control system, and described control circuit 13 passes the feedback collected by main circuit 11 After calculation and processing of the quantity and the given quantity set by the user, a driving signal is generated and input to the driving circuit 12, and the driving circuit 12 generates a driving pulse to control the opening and closing of the main circuit 11.

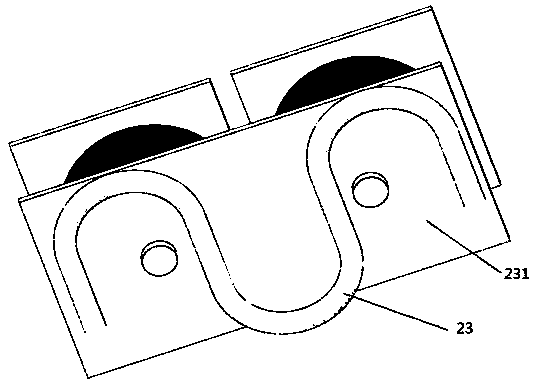

[0040]The water cooling system 2 includes...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com