Processing method for bamboo and rattan

A processing method, bamboo and rattan technology, applied in wood processing equipment, wood heating, manufacturing tools, etc., can solve the problems of poor hand feeling, hand injury, poor quality, etc., and achieve good sterilization effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

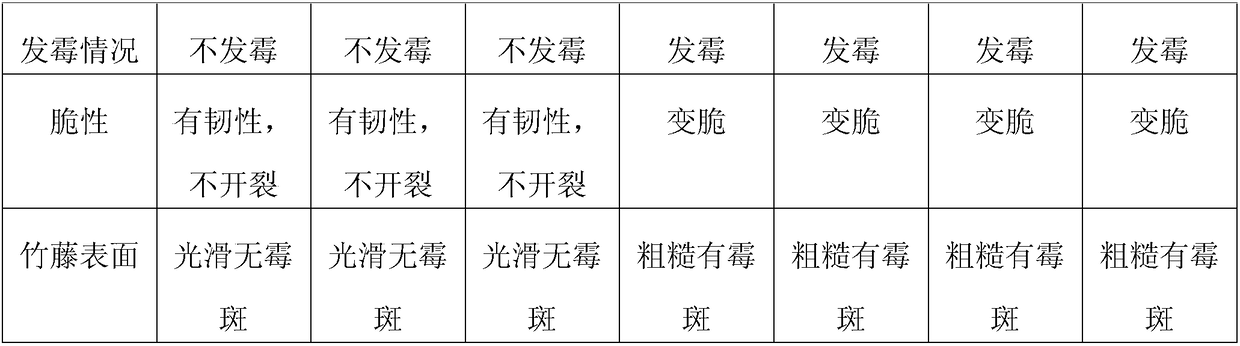

Embodiment 1

[0022] A processing method of bamboo and rattan, comprising the steps of:

[0023] (1) Shaping: Split the bamboo within 2 days after cutting, and make strip-shaped bamboo rattans of different lengths and thicknesses according to needs;

[0024] (2) drying: drying the bamboo and rattan to a moisture content of 5%;

[0025] (3) coating film; taking out bamboo and rattan soaking matter in bamboo and rattan protective agent after 5min; described bamboo and rattan protective agent is made up of the following raw materials of mass parts: 20 parts of bamboo pulp, 8 parts of chitosan, dibutyl maleate - 1 part of vinyl acetate, 100 parts of deionized water, 5 parts of silica airgel, 0.5 part of tea residue wood vinegar;

[0026] (4) Drying: The bamboo and rattan after the coating is dried into a film within 1 min by microwave drying, and the microwave power density of the microwave drying is 0.20mW / cm 2 .

[0027] Wherein, the tea dregs and wood vinegar are prepared by the following...

Embodiment 2

[0031] A processing method of bamboo and rattan, comprising the steps of:

[0032] (1) Shaping: Split the bamboo within 1d after cutting, and make strip-shaped bamboo rattans of different lengths and thicknesses according to needs;

[0033] (2) drying: drying the bamboo and rattan to a moisture content of 10%;

[0034] (3) coating film; taking out bamboo and rattan immersion in bamboo and rattan protective agent after 1min; described bamboo and rattan protective agent is made up of the following raw materials of mass parts: 40 parts of bamboo pulp, 5 parts of chitosan, dibutyl maleate - 5 parts of vinyl acetate, 80 parts of deionized water, 10 parts of silica airgel, 0.1 part of tea residue wood vinegar;

[0035] (4) Drying: the bamboo and rattan after coating are dried into a film within 5 minutes by microwave drying, and the microwave power density of the microwave drying is 0.1mW / cm 2 .

[0036] Wherein, the tea residue wood vinegar is prepared by the following method: p...

Embodiment 3

[0040] A processing method of bamboo and rattan, comprising the steps of:

[0041] (1) Shaping: Split the bamboo within 2 days after cutting, and make strip-shaped bamboo rattans of different lengths and thicknesses according to needs;

[0042] (2) drying: the bamboo rattan is dried to a moisture content of 8%;

[0043] (3) Coating film; Bamboo and rattan immersion is taken out after 3min in bamboo and rattan protective agent; Described bamboo and rattan protective agent is made up of the following raw materials of mass parts: 30 parts of bamboo pulp, 7 parts of chitosan, dibutyl maleate - 3 parts of vinyl acetate, 90 parts of deionized water, 8 parts of silica airgel, 0.3 part of tea residue wood vinegar;

[0044] (4) Drying: the bamboo and rattan after coating are dried into a film within 3 minutes by microwave drying, and the microwave power density of the microwave drying is 0.20mW / cm 2 .

[0045] Wherein, the tea residue wood vinegar is prepared by the following method: ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com