Electromagnetic suspension power generation train system

An electromagnetic levitation and train technology, applied in sliding/floating railway systems, electric vehicles, tunnel systems, etc., can solve the problems of low input-output ratio, large electrical dependence, large electromagnetic radiation, etc. Ensuring safety and comfort, reducing impact and friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

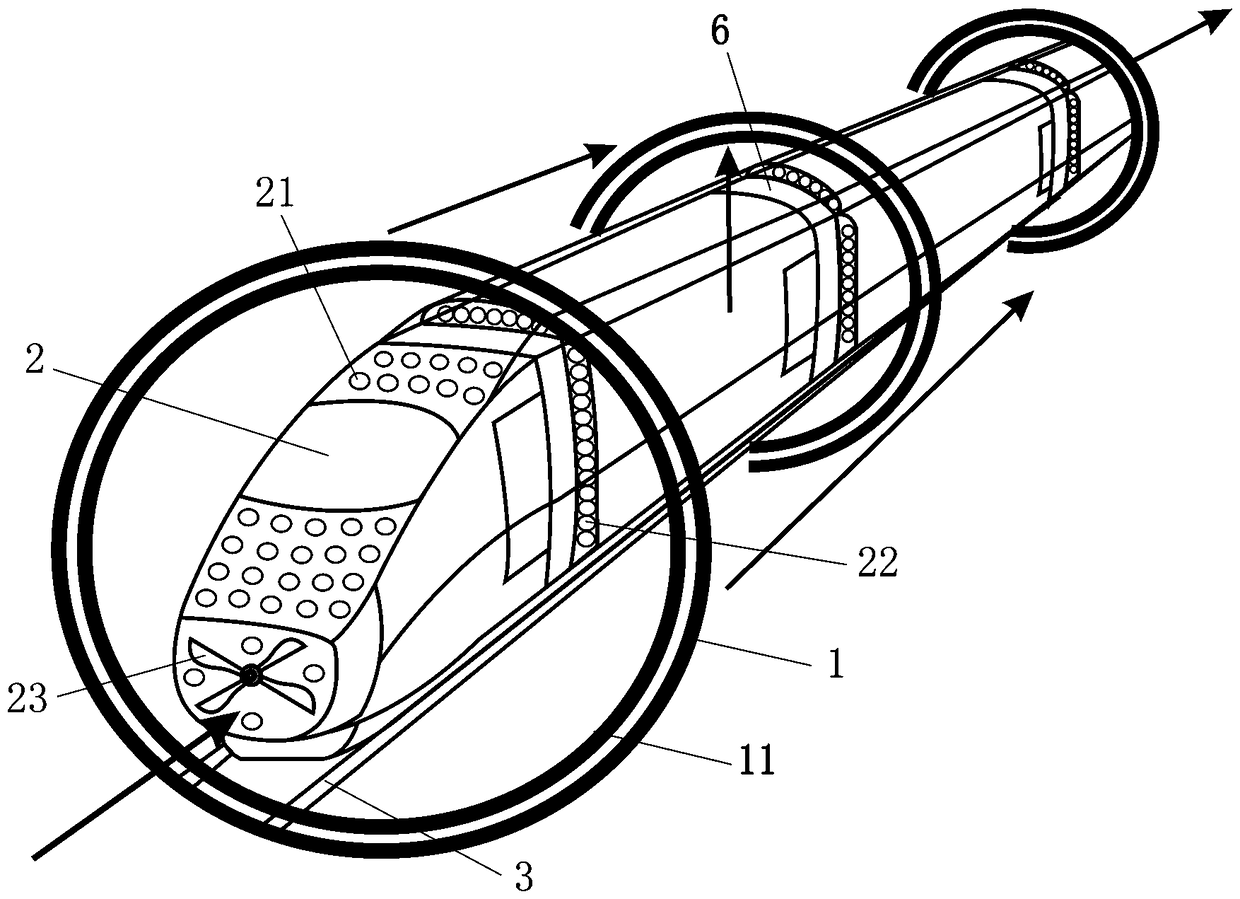

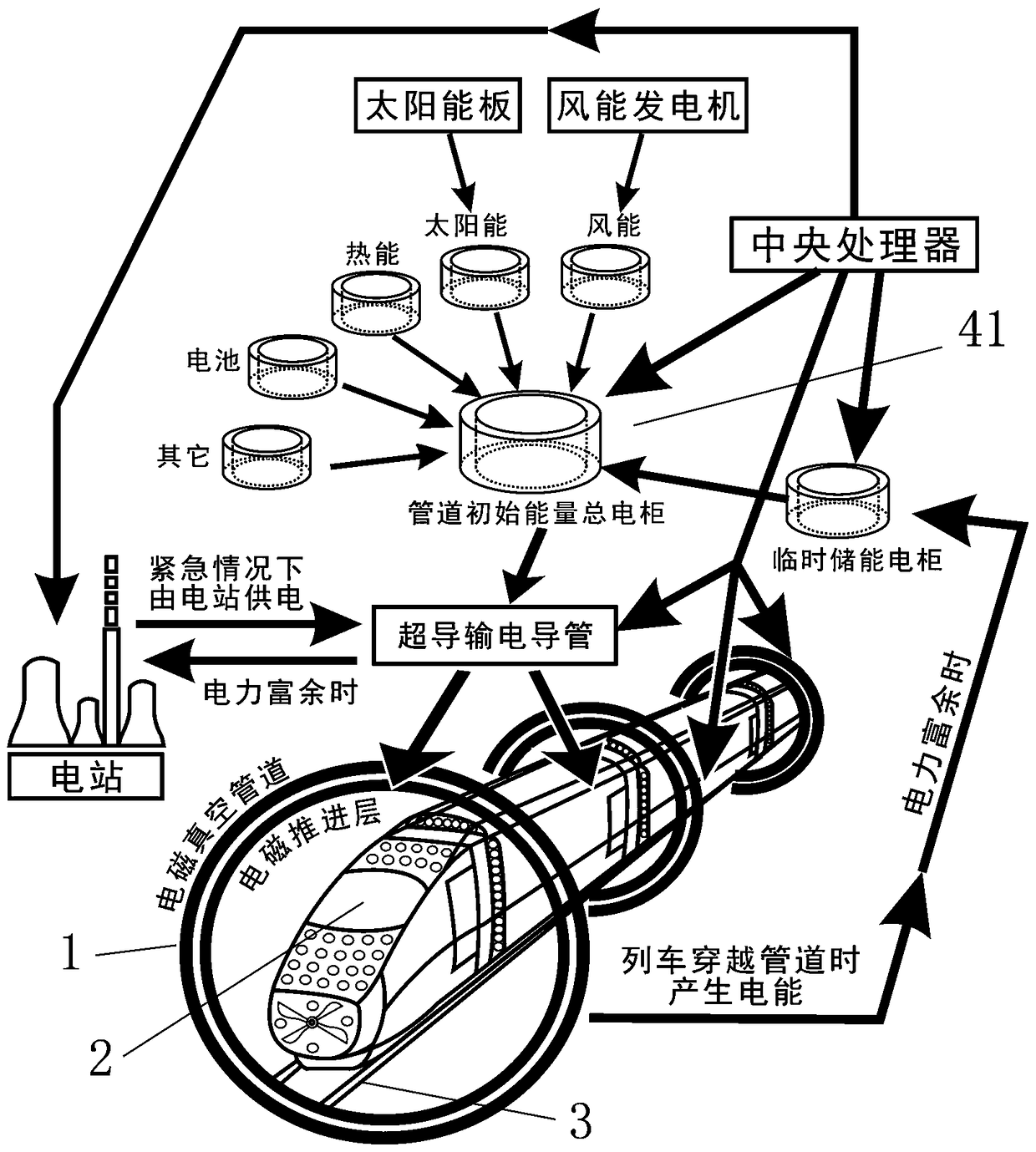

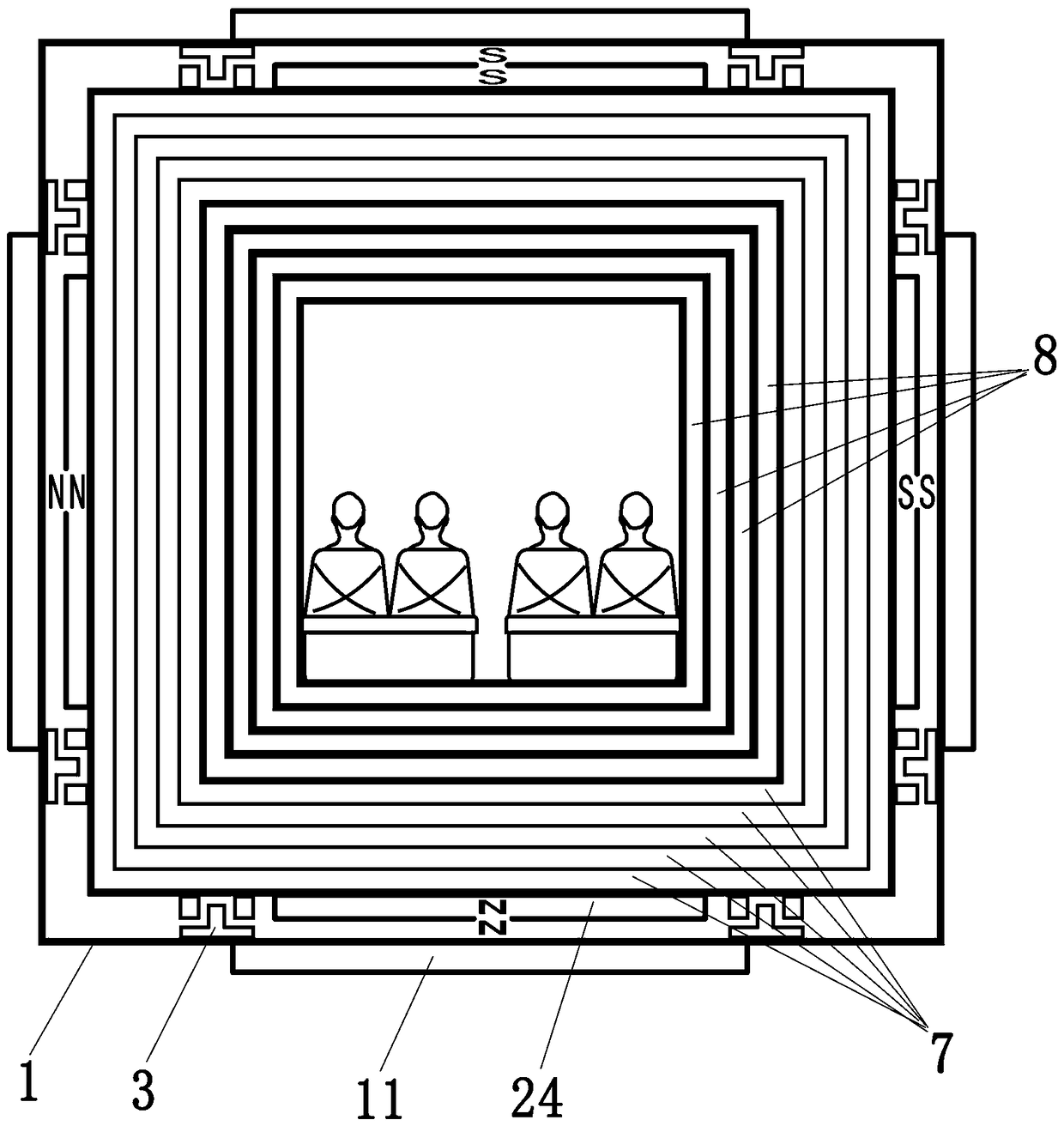

[0034] Such as figure 1 As shown, the electromagnetic levitation power generation train system proposed by the present invention includes: a pipeline 1 , a train 2 inside the pipeline 1 , and a plurality of tracks 3 arranged between the pipeline 1 and the train 2 . Each track 3 includes two rails installed on the inner wall of the pipeline 1, and an outer suspension electromagnet is arranged between the two rails. The body of the train 2 is provided with rails running along the track 3. The rails include two Wheel rails, an inner suspension electromagnet opposite to the outer suspension electromagnet is arranged between the two wheel rails. Such as figure 2 Shown is a schematic diagram of the train power supply relationship in the present invention. The solar and wind energy devices along the railway, as well as the electric energy generated when the train passes through the electromagnetic vacuum pipeline, can supply power for the train 2, and the surplus electric energy c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com