Stack type temporary storage machine capable of solving automatic assembly line blockage

An automatic assembly line and caching machine technology, which is applied in the stacking of objects, conveyors, and unstacking of objects, etc., can solve the problems of not meeting the production needs of large quantities and high efficiency, high manual labor intensity, and changing pallet warehouses, etc. Achieve the effect of mass automatic production, low labor intensity and reasonable structural design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

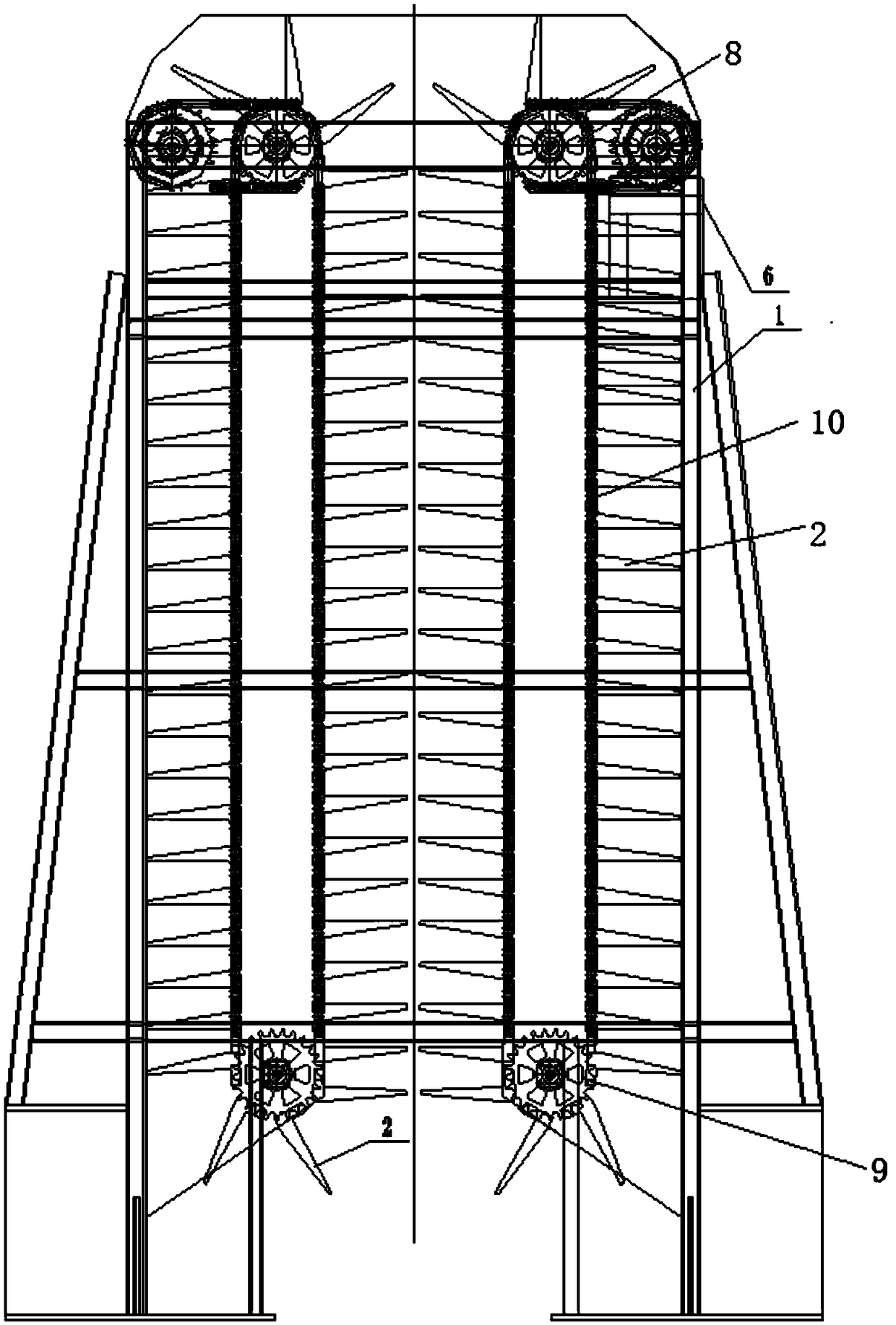

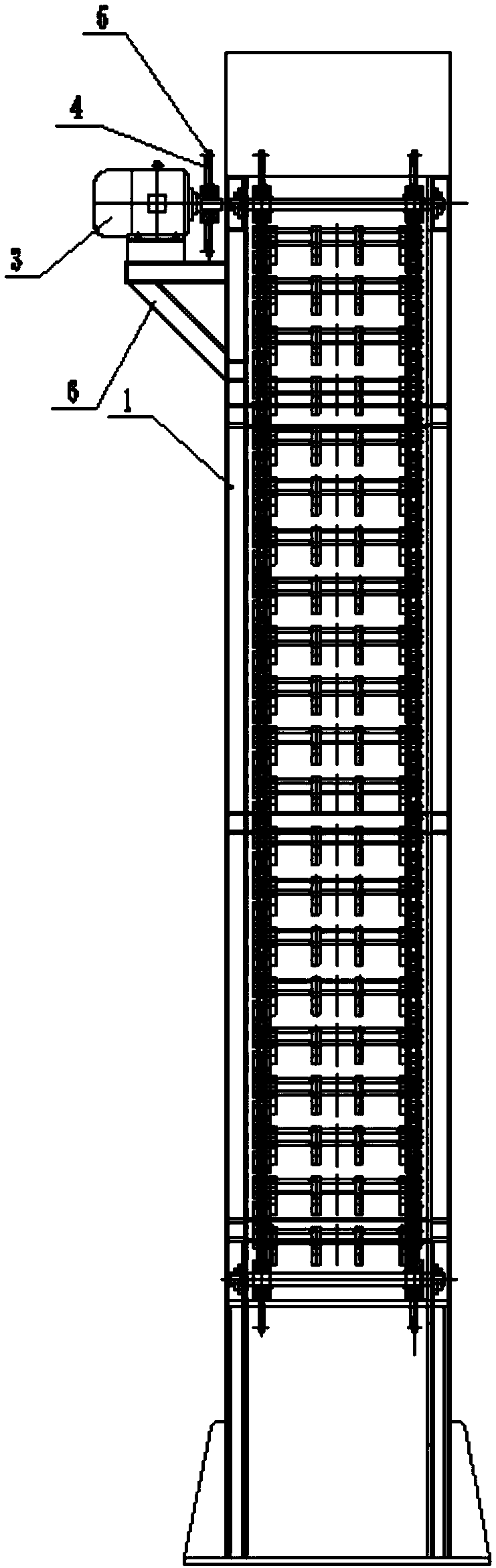

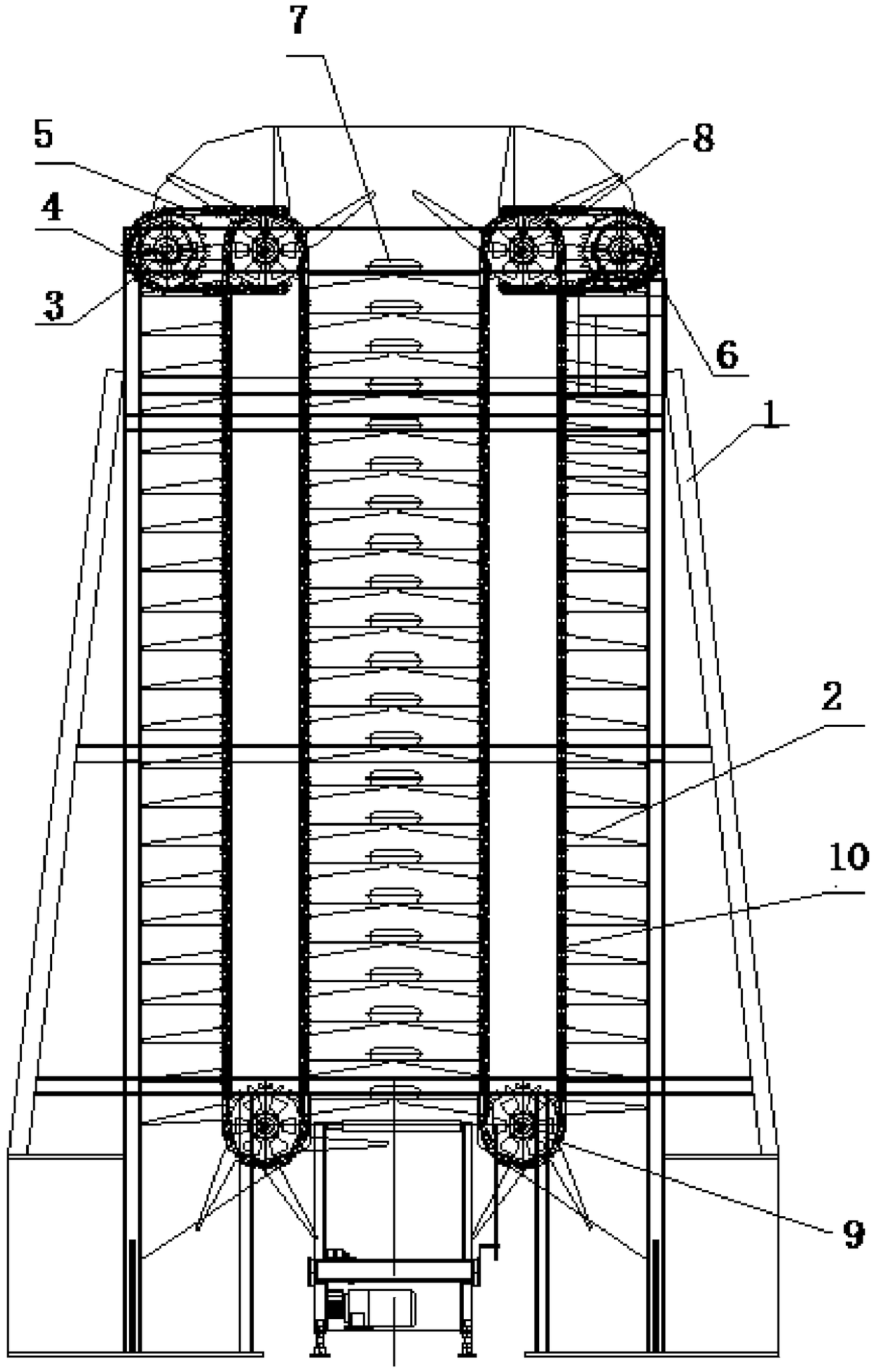

[0022] See attached picture.

[0023] A kind of stack buffer machine that can solve automatic assembly line blockage, comprises the frame 1 erected on the two sides of code waiting machine 11, described frame 1 is respectively installed with upper and lower corresponding drive sprockets through installation bracket 6, and the same Between the driving sprockets on the side, a vertical transmission cycle conveyor chain 10 is installed, and the two cycle conveyor chains 10 are correspondingly arranged side by side, and the grippers 2 corresponding to each other are respectively installed on the cycle conveyor chain 10. The hand 2 can pass between the two conveying rollers of the coding machine 11, the conveying direction of the circulating conveying chain 10 is opposite, and the operation of the circulating conveying chain 10 is driven by its corresponding motor 3 respectively.

[0024] The circular conveying chain 10 is distributed on both sides of the code waiting machine 11 sy...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap