Dye dispersant and preparation method thereof

A technology of dye dispersant and sulfonation reaction, applied in the direction of organic dyes, chemical instruments and methods, dissolution, etc., can solve problems such as environmental impact, increase production costs of enterprises, achieve high safety, reduce usage, and impurity content low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

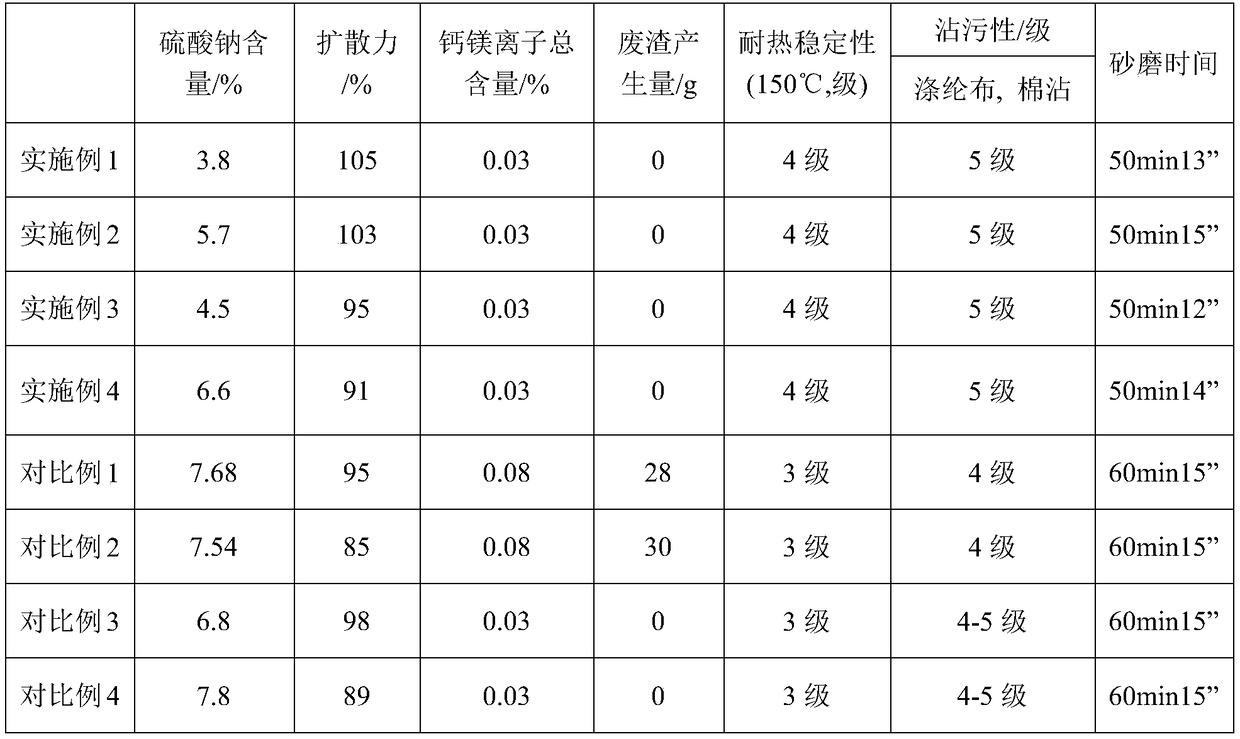

Examples

preparation example Construction

[0027] The present invention at first provides a kind of preparation method of dye dispersant, can comprise the following steps:

[0028] Get naphthalene compound and sulfuric acid to carry out sulfonation reaction;

[0029] Collect the low-boiling organic matter produced in the sulfonation reaction;

[0030] After adding the low-boiling point organic matter into the reaction system of the sulfonation reaction, the reaction is continued to obtain a sulfonation product.

[0031] The preparation method of the dye dispersant of the invention can reduce the amount of sulfuric acid used, and further greatly reduce the generation of waste residue calcium sulfate, thereby achieving the purpose of environmental protection. In addition, the preparation method of the present invention uses low-boiling organic substances in the reaction process without introducing other substances, so that the problem of low purity of the product caused by the introduction of other unknown substances ca...

Embodiment 1

[0049] Weigh 100g of industrial methylnaphthalene and put it into a 500mL reaction vessel with a stirrer and a thermometer, start stirring, heat up to 100°C, add 75g of concentrated sulfuric acid with a mass fraction of 98%, and heat up to 150°C. The reaction was maintained for 1 hour, and then the vacuum pump was turned on, and the pressure of the vacuum environment was controlled to be -0.06~-0.05MPa. Insulate and react for 3 hours, and collect the obtained gasification products; at the same time, the gasification products are condensed, and the low-boiling point organic matter is obtained after layering to remove moisture. Then, 10 g of low-boiling-point organic matter was added dropwise into the reaction vessel, and the reaction was continued for 3 hours to obtain a sulfonated product, and the acid value was tested by sampling. Then cool the sulfonated product to 120°C, add water to make the acid value 20%, and then cool to 80°C. Add 45g of formaldehyde with a mass fracti...

Embodiment 2

[0051] Weigh 100g of industrial methylnaphthalene and put it into a 500mL reaction vessel with a stirrer and a thermometer, start stirring, heat up to 100°C, add 83g of sulfuric acid with a mass fraction of 98%, and heat up to 150°C. The reaction was maintained for 1 hour, and then the vacuum pump was turned on, and the pressure of the vacuum environment was controlled to be -0.06~-0.05MPa. Insulate and react for 3 hours, and collect the obtained gasification products; at the same time, the gasification products are condensed, and the low-boiling point organic matter is obtained after layering to remove moisture. Then, 10 g of low-boiling-point organic matter was added dropwise into the reaction vessel, and the reaction was continued for 3 hours to obtain a sulfonated product, and the acid value was tested by sampling. Then cool the sulfonated product to 120°C, add water to make the acid value 20%, and then cool to 80°C. 45g of formaldehyde with a mass fraction of 37% was add...

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com