Essence for increasing smoke moistness of heat-not-burn novel cigarettes, and preparation method and application of essence

A heat-not-burn, cigarette smoke technology, applied in the field of cigarette flavors and fragrances, can solve the problems of lack of natural tobacco leaf oil, throat discomfort for smokers, heat-not-burn cigarettes, etc., and achieves easy industrial production, reduced dryness, and low cost. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

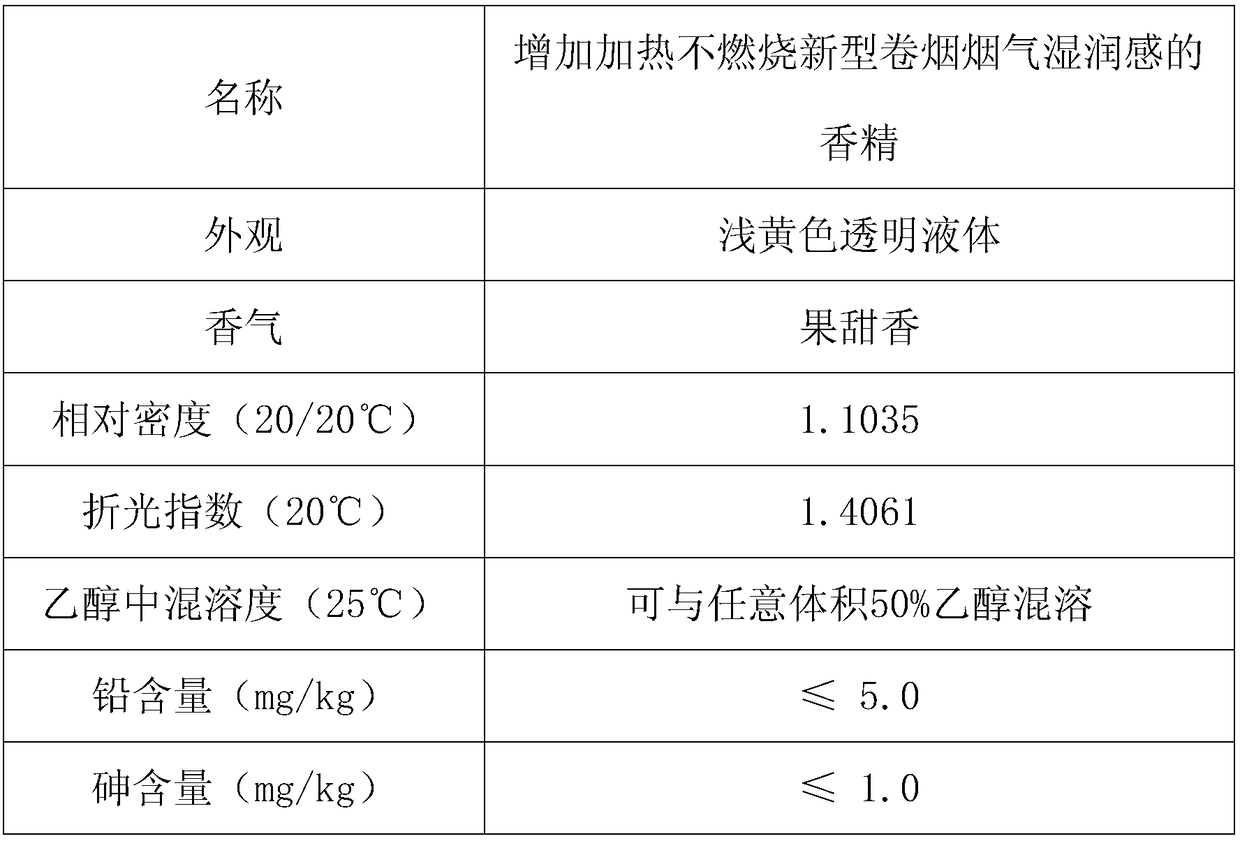

Image

Examples

Embodiment 1

[0033] Example 1: A flavor that increases the moistness of smoke in heat-not-burn cigarettes. The specific steps are as follows: 18.2 parts of ethanol, 1 part of sweet orange oil, 2 parts of pomelo oil, 1.5 parts of lemon oil, and magnolia flower Add 0.3 parts of oil, 2 parts of β-caryophyllene, 57 parts of glycerin, 10 parts of pear extract, and 8 parts of distilled water into the mixing container in sequence, mix and stir for 2 to 4 hours, stand still for 24 to 48 hours, and use a pore size of 0.8 The filtrate with a relative density of 1.10-1.30 obtained by filtering out the sediment with a micron filter membrane is the flavor that increases the moistness of the smoke of the new heat-not-burn cigarette.

[0034] The essence prepared in Example 1 to increase the moistness of the heat-not-burn cigarette smoke was diluted 6 times with 70% ethanol, sprayed directly on the shredded tobacco made of reconstituted tobacco leaves with a throat sprayer, and placed in a 40°C drying ove...

Embodiment 2

[0035] Example 2, an essence that increases the moistness of smoke in heat-not-burn cigarettes. The specific steps are as follows: 15 parts of ethanol, 1.5 parts of sweet orange oil, 2 parts of pomelo oil, 1 part of lemon oil, and magnolia flower Add 0.6 parts of oil, 1.9 parts of β-caryophyllene, 58 parts of glycerin, 14 parts of pear extract, and 6 parts of distilled water into the stirring container in sequence, stir for 2-4 hours after mixing, and stand still for 24-48 hours. The filtrate with a relative density of 1.10-1.30 obtained by filtering out the sediment with a micron filter membrane is the flavor that increases the moistness of the smoke of the new heat-not-burn cigarette.

[0036] The essence prepared in Example 2 to increase the moistness of the heat-not-burn cigarette smoke was diluted 6 times with 70% ethanol, sprayed directly on the shredded tobacco made of reconstituted tobacco leaves with a throat sprayer, and placed in a 40°C drying oven After 2 to 4 hour...

Embodiment 3

[0037] Example 3, an essence that increases the moistness of smoke in heat-not-burn cigarettes. The specific steps are as follows: 12 parts of ethanol, 2 parts of sweet orange oil, 1.5 parts of pomelo oil, 1 part of lemon oil, and magnolia flower Add 0.6 parts of oil, 3 parts of β-caryophyllene, 56 parts of glycerin, 18 parts of pear extract, and 5.9 parts of distilled water into the stirring container in sequence, stir for 2-4 hours after mixing, and stand still for 24-48 hours, using a pore size of 0.8 microns The filtrate with a relative density of 1.10 to 1.30 is obtained by filtering the sediment through a filter membrane, which is the essence for increasing the moistness of the heat-not-burn cigarette smoke.

[0038] The essence prepared in Example 3 to increase the moistness of the heat-not-burn cigarette smoke was diluted 6 times with 70% ethanol, sprayed directly on the shredded tobacco made of reconstituted tobacco leaves with a throat sprayer, and placed in a 40°C dr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com