Efficient biogas digester for removing slag

A biogas digester and high-efficiency technology, applied in biochemical cleaning devices, gas production bioreactors, bioreactors/fermenters for specific purposes, etc., can solve problems such as low efficiency of biogas generation and troublesome cleaning of biogas residues, and achieve reduction Effects of resistance, reduction of energy loss, and improvement of activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

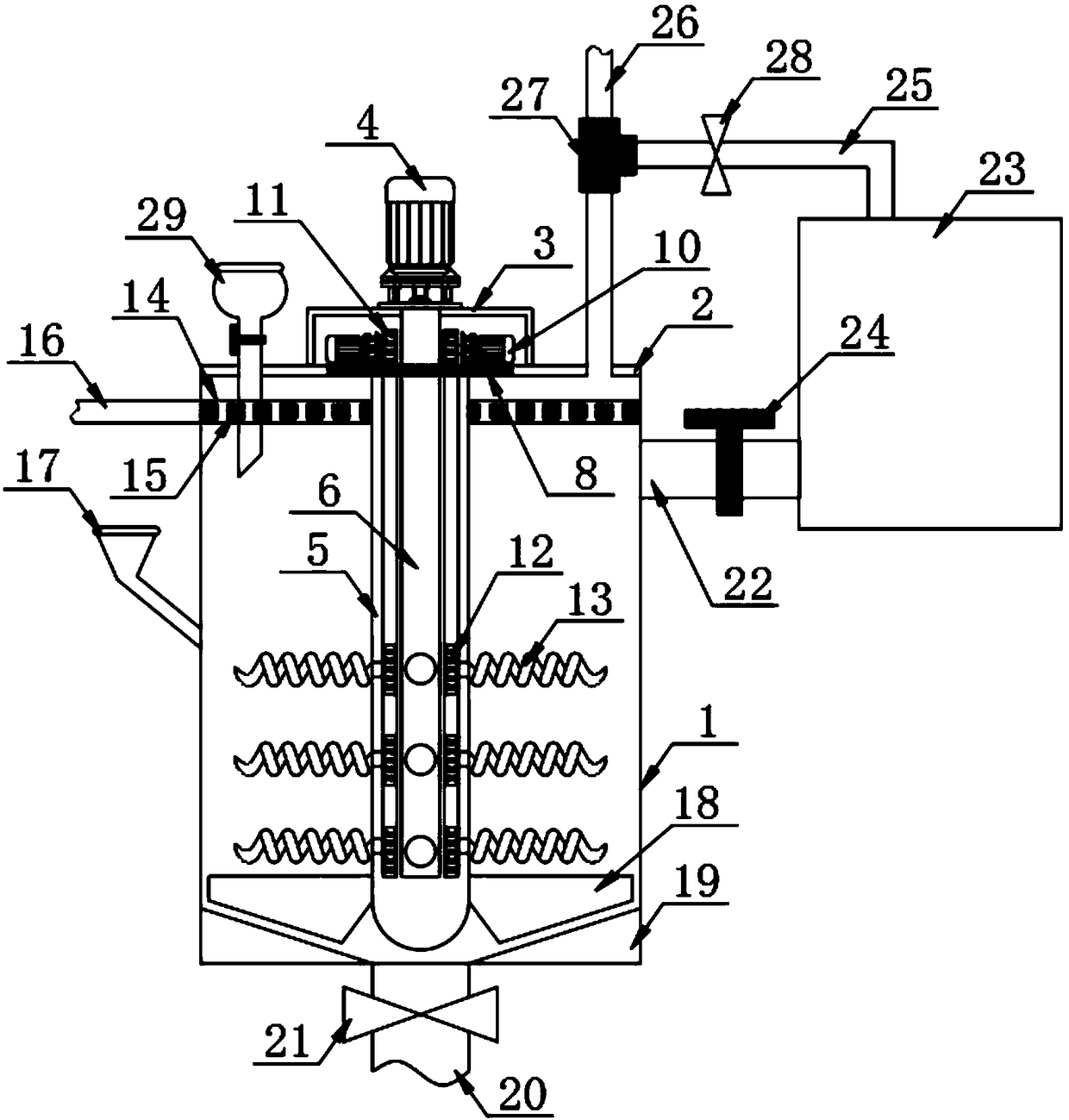

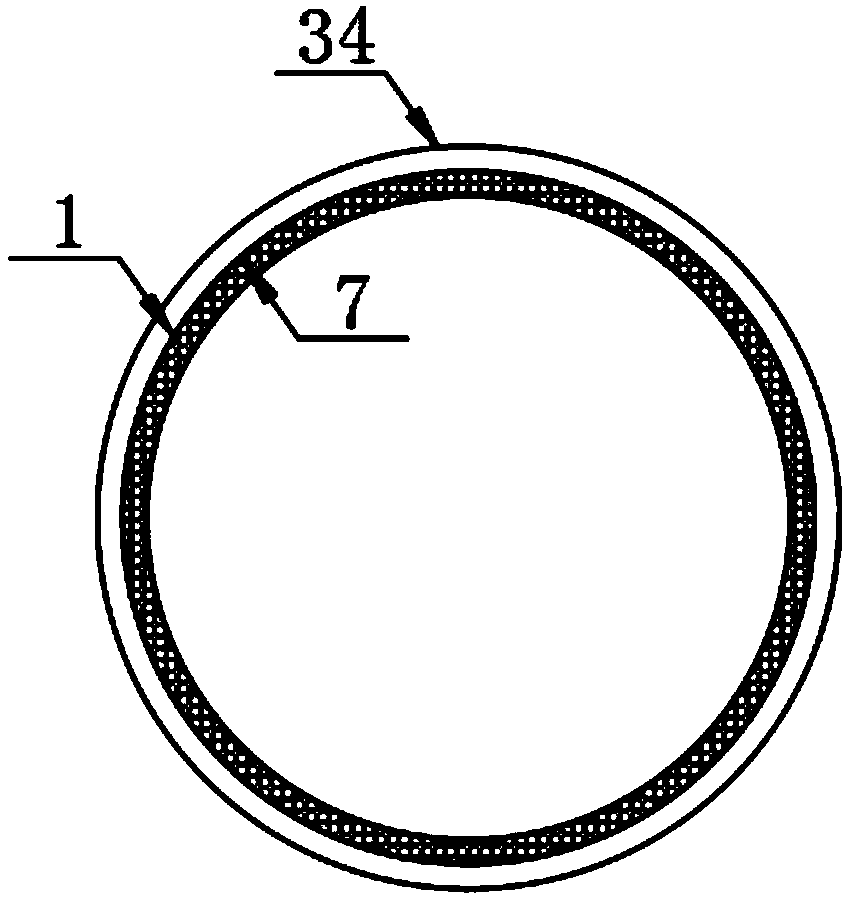

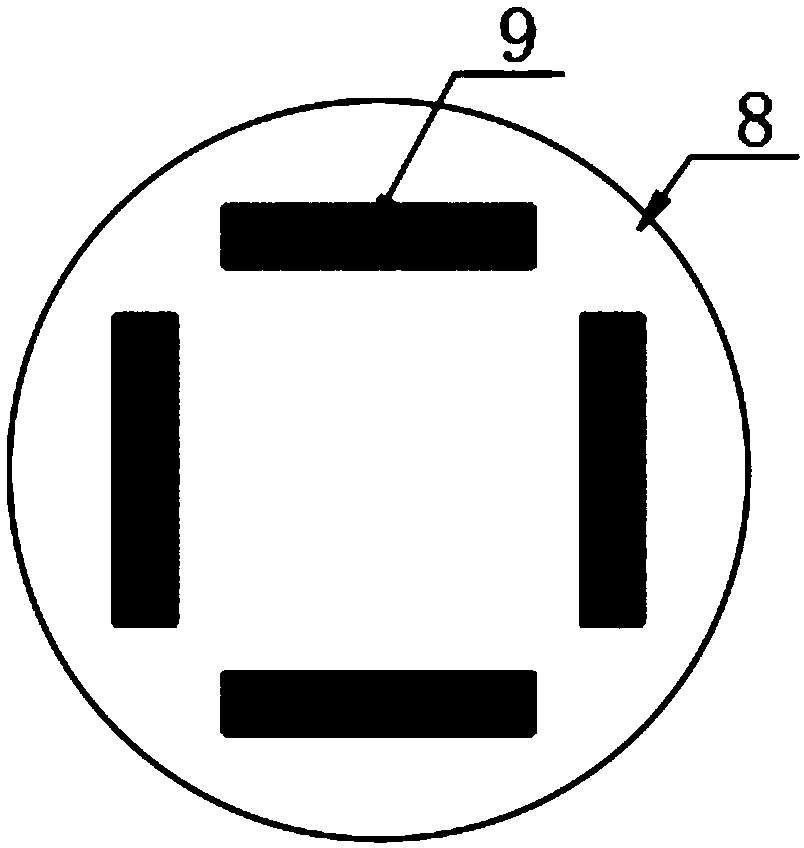

[0028] The present invention provides such Figure 1-6 A high-efficiency biogas digester that is convenient for slag removal is shown, comprising an anaerobic fermentation tank 1, a tank cover 2 is provided on the top of the anaerobic fermentation tank 1, and a mounting frame 3 is arranged on the top of the tank cover 2. The installation One side of the rack 3 is provided with a bacteria hopper 29 and the other side is provided with a second exhaust pipe 26, and the drop pipe of the bacteria hopper 29 and the second exhaust pipe 26 are all connected to the anaerobic fermentation tank 1. The installation The top of the frame 3 is provided with a positive and negative motor 4, and the tank cover 2 is embedded with a disk 8, the output shaft of the positive and negative motor 4 is connected to the disk 8, and the bottom of the disk 8 is provided with an outer shaft 5, Stirring blades 18 are provided on the circumferential side surface of the bottom end of the outer shaft 5, and a...

Embodiment 2

[0035] Further, in the above technical solution, one side of the stirring blade 18 is set as a plane and the other side is set as a raised arc surface, and the arc surface is tapered outwardly, which can greatly reduce the rotation speed of the stirring blade 18. The resistance of the mixture received during the process, thereby reducing the energy loss of the forward and reverse motor 4 when it works.

[0036] Further, in the above technical solution, the bottom of the anaerobic fermentation tank 1 is provided with a wedge-shaped platform 19, and the top of the wedge-shaped platform 19 is set as a downward inclined surface, and the bottom end of the inclined surface is matched with the slag discharge pipe 20 , can be used to guide the discharge of biogas residues, avoid residues of biogas residues at the corners inside the anaerobic fermentation tank 1 and increase the difficulty of cleaning biogas residues.

[0037] Further, in the above technical solution, the connecting pi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com