Intelligent modular efficient heat treatment method

A heat treatment method and modular technology, applied in heat treatment equipment, heat treatment process control, manufacturing tools, etc., can solve the problems of unstable heat treatment quality, large energy consumption, and high labor intensity of batch parts, and achieve lean production management and reduce Labor intensity, the effect of reducing labor costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

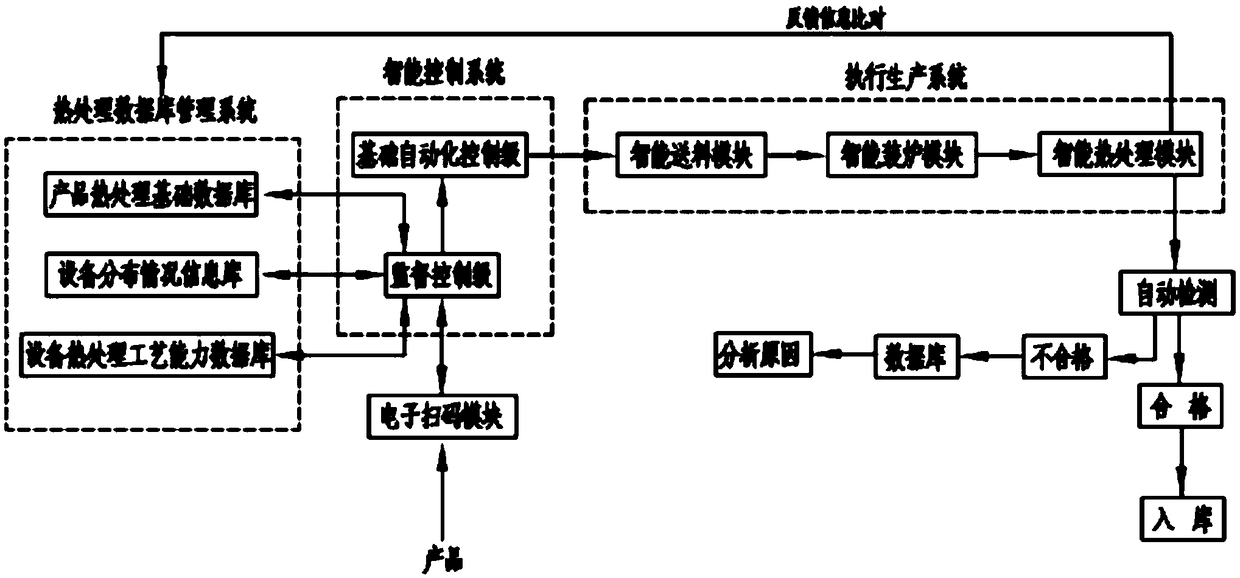

[0035] Such as figure 1 , figure 2 , image 3 As shown, what is provided in this embodiment is an intelligent modular high-efficiency heat treatment method, including a heat treatment database management system, an intelligent control system, an electronic code scanning module, and an execution production system;

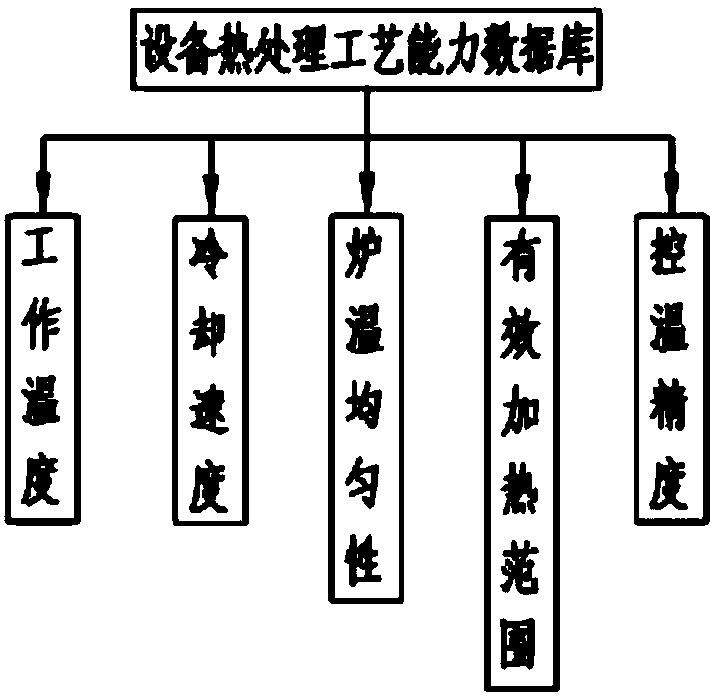

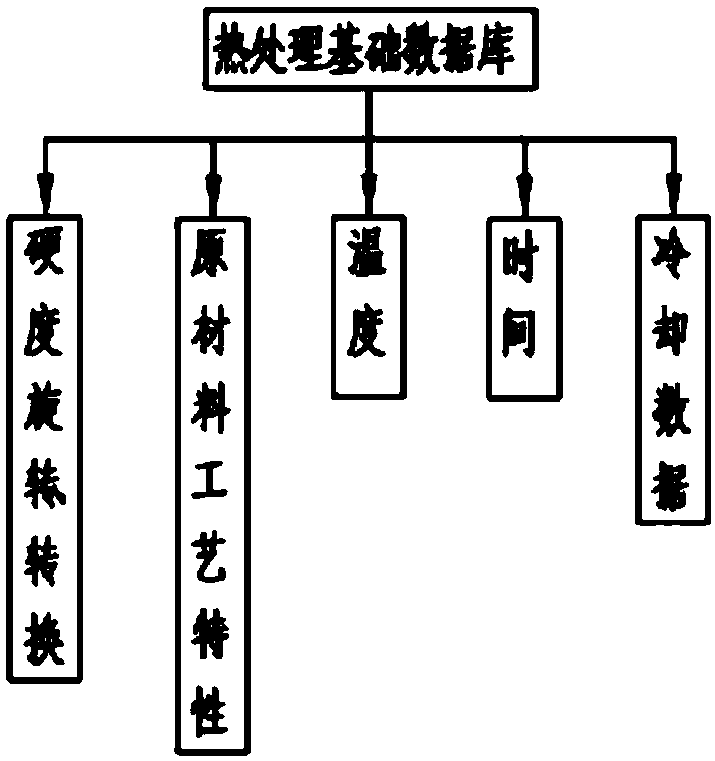

[0036] The heat treatment database management system includes a product heat treatment basic database, a heat treatment equipment distribution information database, and an equipment heat treatment process capability database;

[0037] The intelligent control system includes a supervisory control level and a basic automation control level. The supervisory control level accepts the heat treatment process automatically generated by the heat treatment data management system, and transmits relevant parameter values to the basic automation control level. The basic automation control level controls The external equipment completes the heat treatment process of the par...

Embodiment 2

[0056] like Figure 4 As shown, the parts that are the same as or corresponding to those in the first embodiment are marked with the corresponding reference numerals in the first embodiment. For the sake of simplicity, only the differences from the first embodiment are described below. The difference between the second embodiment and the first embodiment is that the electronic code scanning module is set as an RFID reading module, and the corresponding electronic scanning device is set as an RFID reading device, and the product to be processed is hung There is an RFID smart label with pre-input information. After the product enters the heat treatment workshop, use the RFID reading device to read the information on the RFID smart label, feed it back to the heat treatment database management system to generate the corresponding heat treatment production process data, and then transmit the information to the intelligent control system. Control the subsequent heat treatment proces...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com