Coal cutter for lump coals in hard thin seams and coal cutting method

A coal mining machine and thin coal seam technology, applied in cutting machinery, ground mining, earth drilling and mining, etc., can solve problems such as the difficulty of lifting the roof safety maintenance, the reduction of the working efficiency of the coal mining machine, and the prohibition of blast mining hazards, etc. Achieve the effect of improving cutting force, compact structure and small operating space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

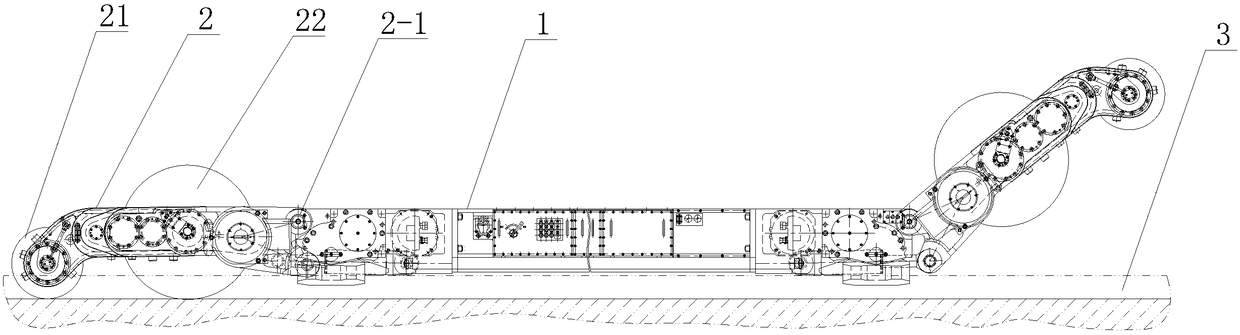

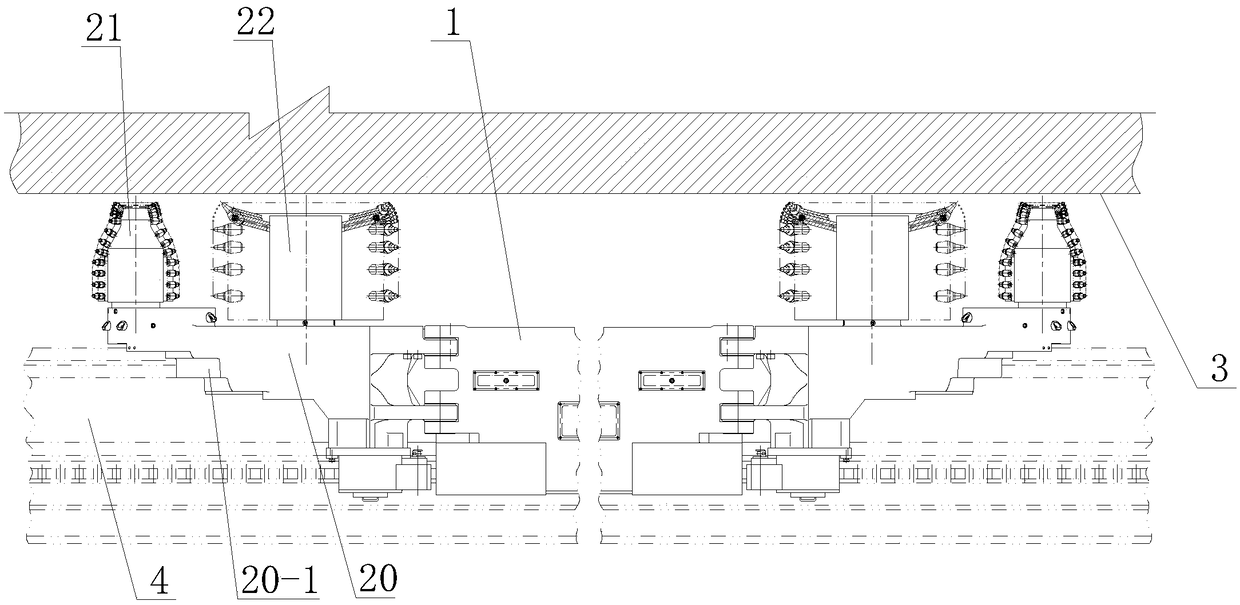

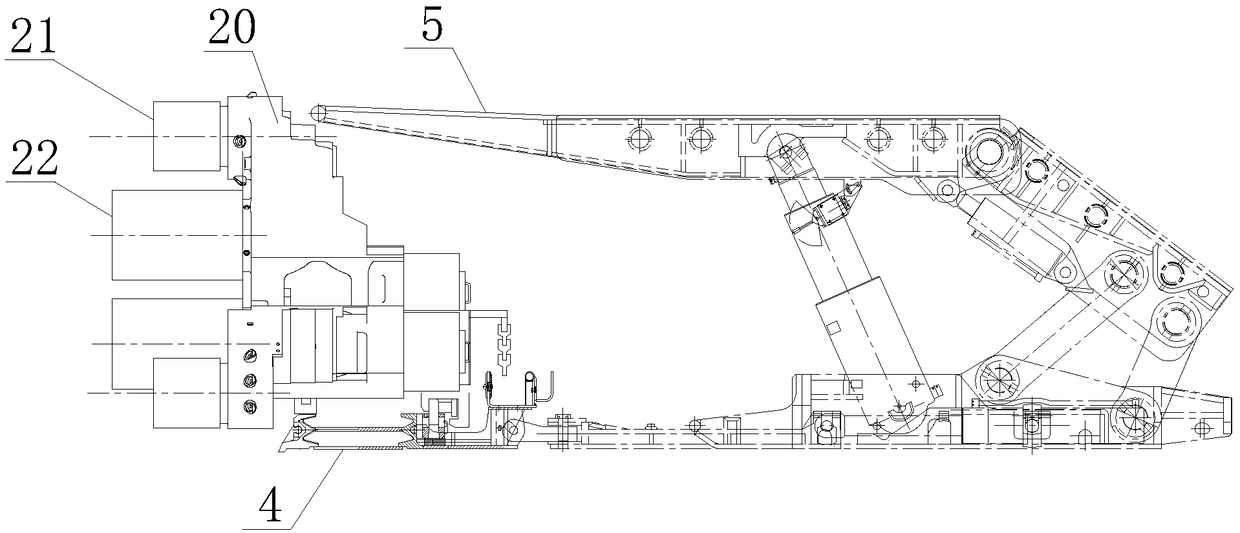

[0022] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0023]As shown in the figure, a hard thin coal seam lump coal shearer includes a shearer body 1, and the two ends of the shearer body 1 are symmetrically hinged with a cutting part 2 through hinged ears 2-1 respectively. The cutting part 2 is movably connected with the shearer body 1 through the height-adjusting oil cylinder. The cutting part 2 is driven by the motor 11 set in the cutting part housing 20 through the deceleration and splitting transmission system 12. Each cutting part A small cutting drum 21 and a large cutting drum 22 are all arranged side by side towards the coal wall 3 sides on the cutting part housing 20 of the part 2, and the diameter of the small cutting drum 21 is smaller than the diameter of the large cutting drum 22, wherein the The small cutting drum 21 is located at the end away from the shearer body 1; the small cutting drum 21 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com