Plugging and draining combined treatment method for water leakage at tunnel secondary lining construction joint

A technology of blocking and drainage combination and construction joints, which is applied in tunnel lining, tunnel, drainage and other directions, can solve the problems of no blocking and drainage combination system, no natural drainage, affecting the safety of the structure in use, etc., to avoid lining cracking, Significant economic and social benefits and less destructive effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Specific embodiments of the present invention are provided below, and it should be noted that the present invention is not limited to the following specific embodiments, and all equivalent transformations done on the basis of the technical solutions of the present application all fall within the scope of protection of the present invention.

[0020] A method for combined treatment of seepage water plugging and draining in construction joints of the second lining of the tunnel, comprising the following steps:

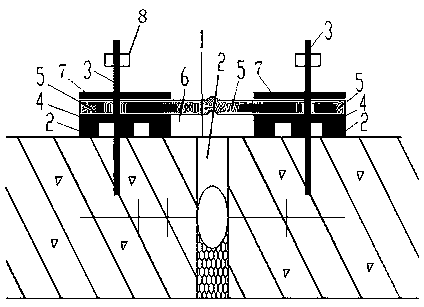

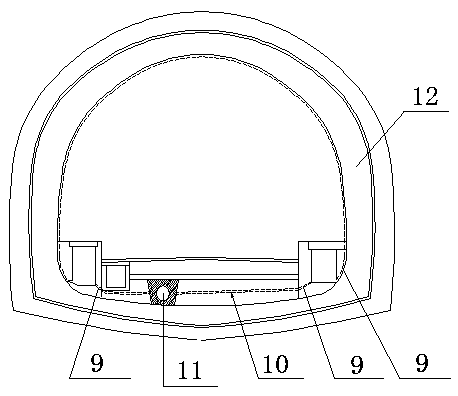

[0021] (1) Chisel off the original filling material of the secondary lining 12 construction joint 1, chisel to the surface of the buried waterstop, clean the inner surface of the construction joint 1, and remove the oil, attachments, dust, etc. on the inner surface of the construction joint 1 gap, Ensure that the inner surface of the construction joint 1 is dry, smooth and clean to prevent poor bonding. After cleaning, use waterproof sealant 2 to compact and fill t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com