Visual measuring device and measuring method for curved plate-rotor gap of air pre-heater

A technology of air preheater and measuring device, which is applied in the direction of measuring device, optical device, instrument, etc., can solve the problems of unmeasurable adjustment of the gap between the arc plate and the rotor, overload of the air preheater drive motor, invisible, etc. The measurement effect is stable for a long time, the operation efficiency is improved, and the effect of convenient and precise adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The present invention will be further elaborated below in conjunction with the accompanying drawings and specific embodiments.

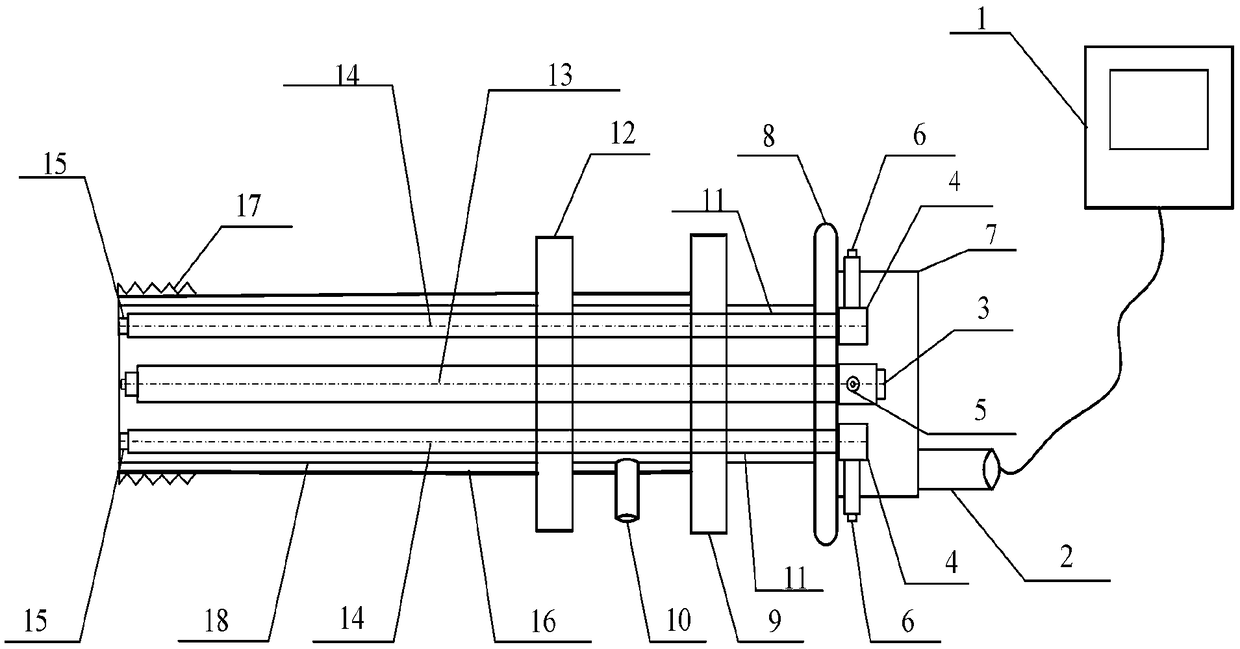

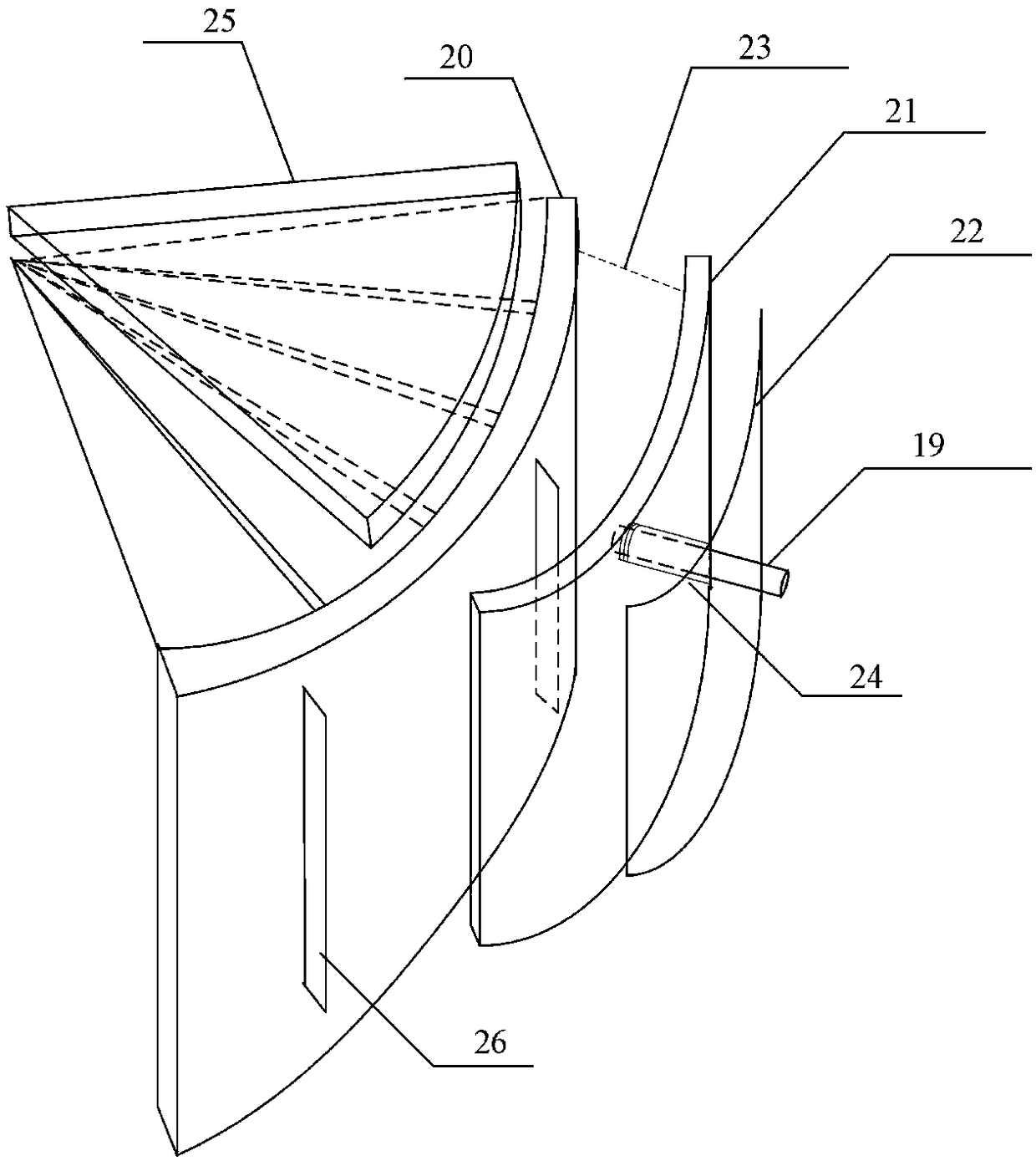

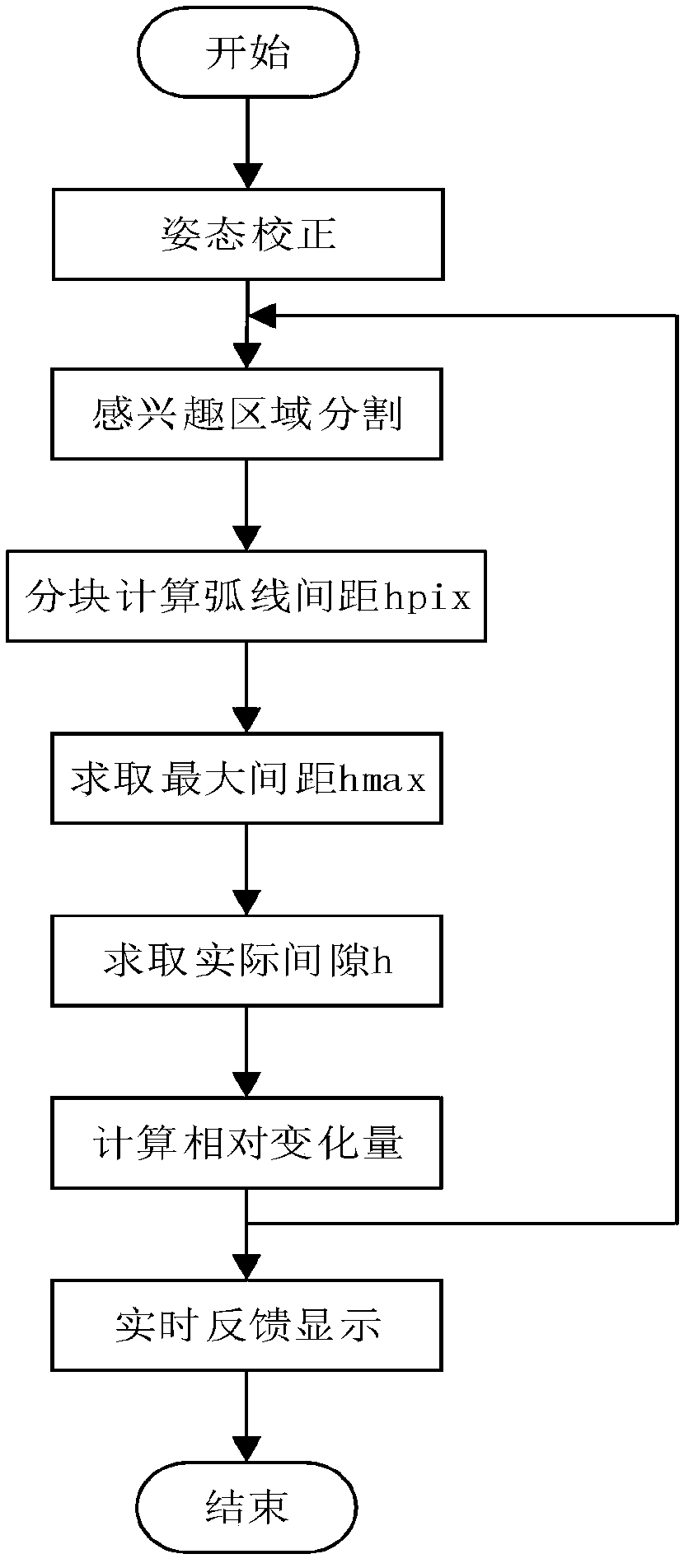

[0040] like figure 1 As shown, the visual measurement device for the air preheater arc plate and the rotor gap includes a video acquisition unit and a supplementary light mechanism arranged on the installation body; the video acquisition unit and supplementary light mechanism include a camera 3 installed on the outside of the equipment mounting seat 8 And the two-line laser light source 4, and the extension lens 13 and the two-line laser pipeline 11 and the word laser head 15 installed on the inside of the equipment mounting seat 8; The line laser pipeline 11 and the one-word laser head 15 are connected to each other; the inner cavity of the double-line laser pipeline 11 is the laser optical path 14, and the double-line laser pipeline 11 and the extended lens 13 are made as an integrated three-hole pipeline parallel to the axis line The struc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com