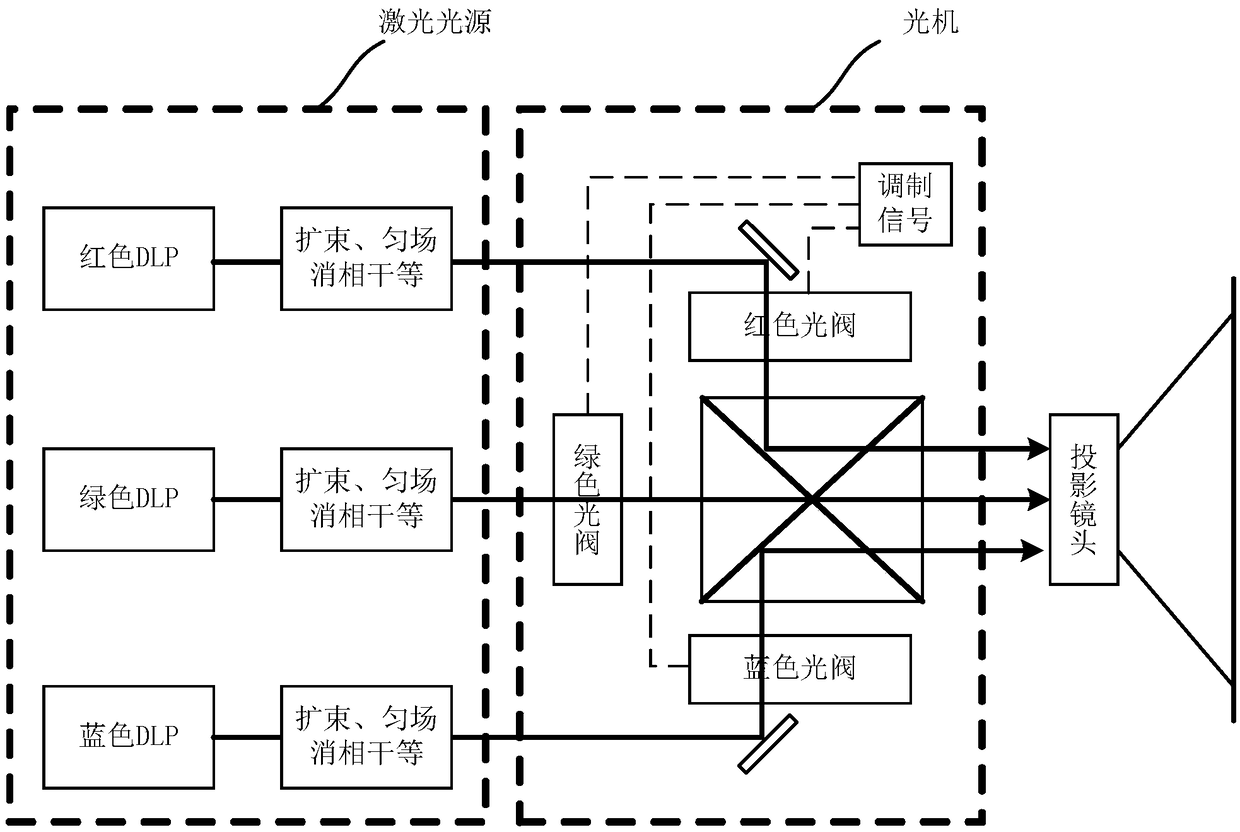

Laser source and laser projector

A laser light source and laser beam technology, applied in the optical field, can solve the problems of limited light-receiving area, damage to the fiber coating, low light resistance power density, etc. cooling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

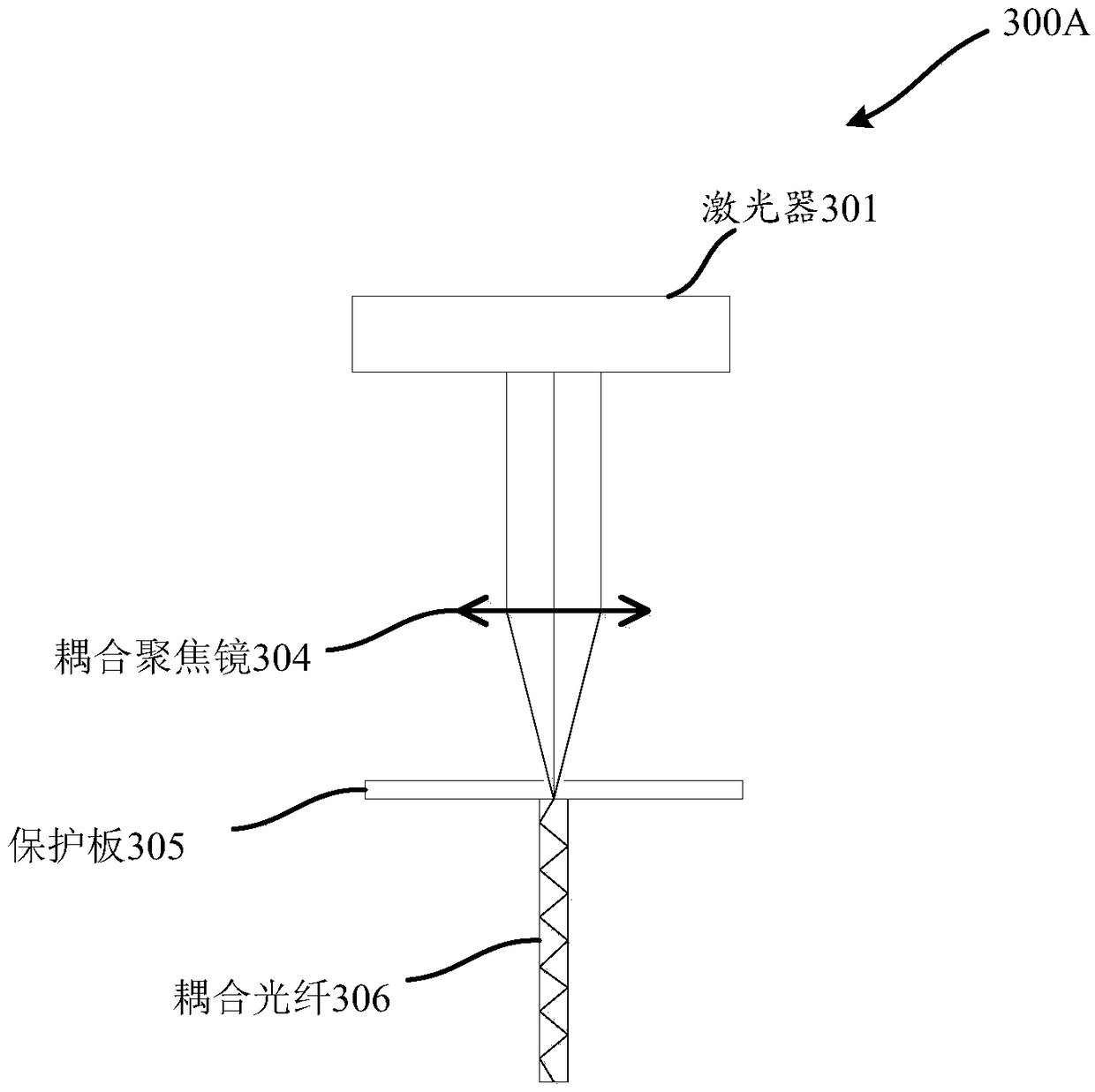

[0032] The laser light source and the laser projector provided by the embodiments of the present application are provided with a protective plate. Based on the protective plate, when the laser spot is shifted, the coupling fiber can be prevented from being irradiated by the offset laser spot caused by the cladding layer on the end face of the coupling fiber. damage.

[0033] The embodiments of the present application will be described in detail below with reference to the accompanying drawings, taking a laser light source applied to a laser projector as an example.

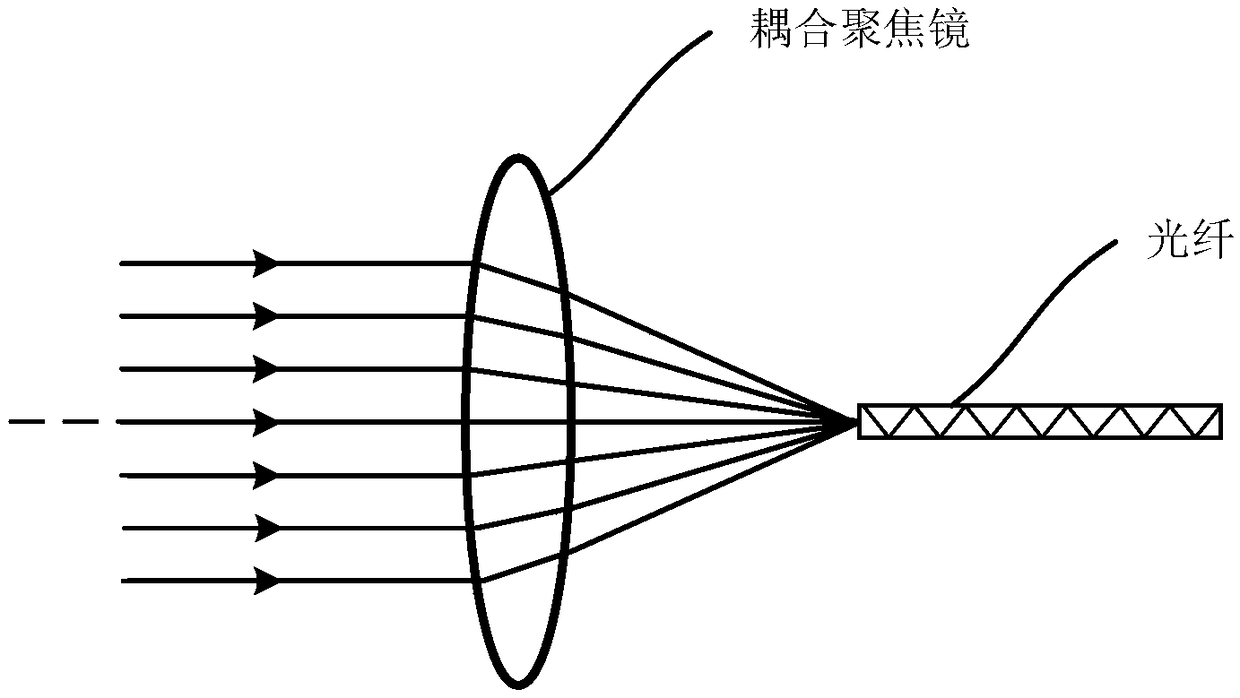

[0034] see Figure 3A and Figure 3B , respectively, are schematic structural diagrams of the laser light sources provided in the embodiments of the present application.

[0035] like Figure 3A As shown, the laser light source 300A includes a laser 301 , a coupling focusing mirror 304 and a protective plate 305 sequentially arranged on the laser light path emitted by the laser 301 . The protective plate 305 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com