Fault simulation system and method for serial bus

A technology of serial bus and fault simulation, applied in faulty hardware testing methods, detecting faulty computer hardware, instruments, etc., can solve the problem of low real-time performance and achieve high real-time performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

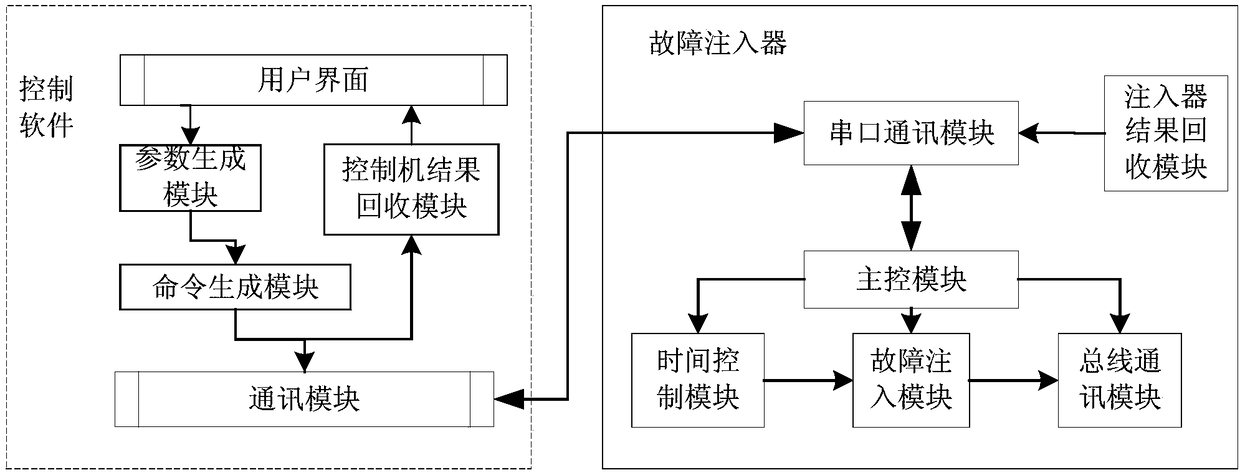

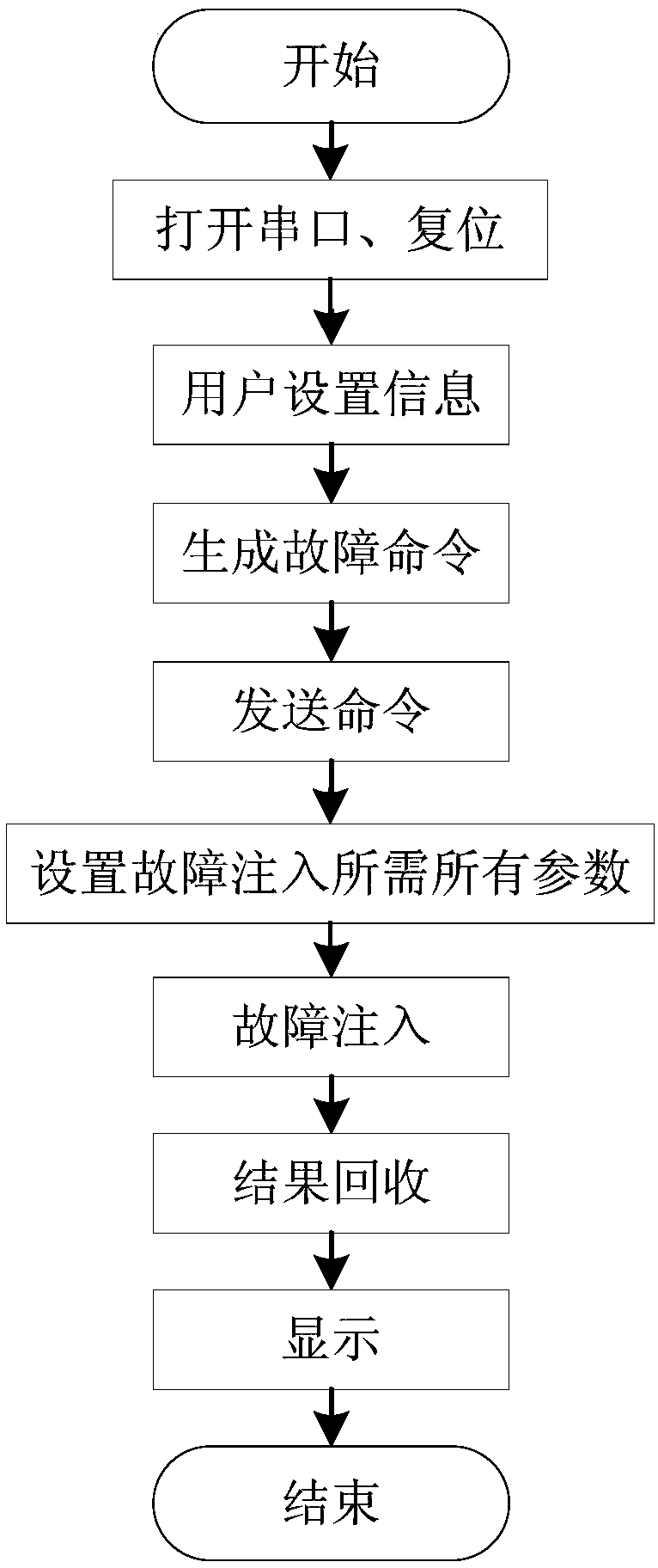

[0036] Specific implementation mode one: combine figure 1 This embodiment is described, the serial bus fault simulation system provided in this embodiment includes a control machine and a fault injector;

[0037] The control machine provides a human-computer interaction mode, generates a fault command according to user requirements, sends the fault command to the fault injector, and receives the injection result and the target system state fed back by the fault injector (that is, the state of the bus during the fault injection process) , and feed it back to the user;

[0038] The fault injector adopts field programmable logic device FPGA, and according to the fault command from the control machine, all parameters required for fault injection are set, and after receiving the data from the serial bus, it sends data to the data according to the set parameters. Inject faults in it, send the modified data to the serial bus, and return the injection results and target system status...

specific Embodiment approach 2

[0039] Embodiment 2: The difference between this embodiment and Embodiment 1 is that the control machine includes: a parameter generation module, a command generation module, a communication module, and a control machine result recovery module;

[0040] The parameter generation module generates fault parameters that can be recognized by the fault injector according to user requirements; the parameter generation module should generate a specific value for all registers inside the fault injector; during the fault injection process, the parameter generation module only needs to generate Just inject the value of the relevant register once.

[0041] The command generation module obtains all generated fault parameter values from the parameter generation module, packs these values into a fault command, and stores all fault commands in the sending data cache, waiting for the communication module to send to fault injector;

[0042] The communication module is responsible for commu...

specific Embodiment approach 3

[0045] Specific embodiment three: the difference between this embodiment and specific embodiment one or two is that the fault injector includes: a serial port communication module, a main control module, a fault injection module, a time control module, a bus communication module, and injector result recovery module;

[0046] The serial port communication module, the serial port communication module is a connection channel between the fault injector and the control machine, and is used to communicate with the control machine; the serial port communication module receives the fault command from the control machine, passes the fault command to the main control module, and Transfer the injection result sent by the injector result recovery module and the target system state to the control machine;

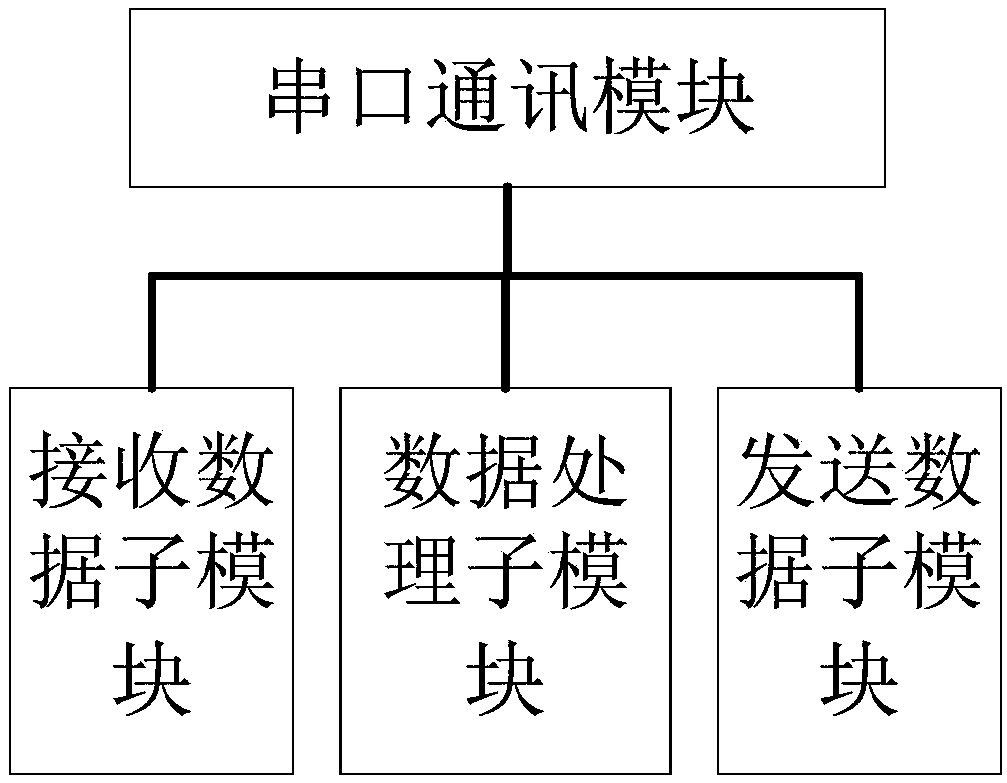

[0047] The serial communication module is divided into three parts: receiving data sub-module, data processing sub-module and sending data sub-module, such as figure 2 shown. The rec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com