Surface defect detection method based on positive case training

A defect detection and positive example technology, applied in image analysis, image enhancement, instruments, etc., can solve the problems of complex production environment changes, difficult to obtain defect samples and manual annotation, etc., to achieve low labor cost, easy implementation, and good interference. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

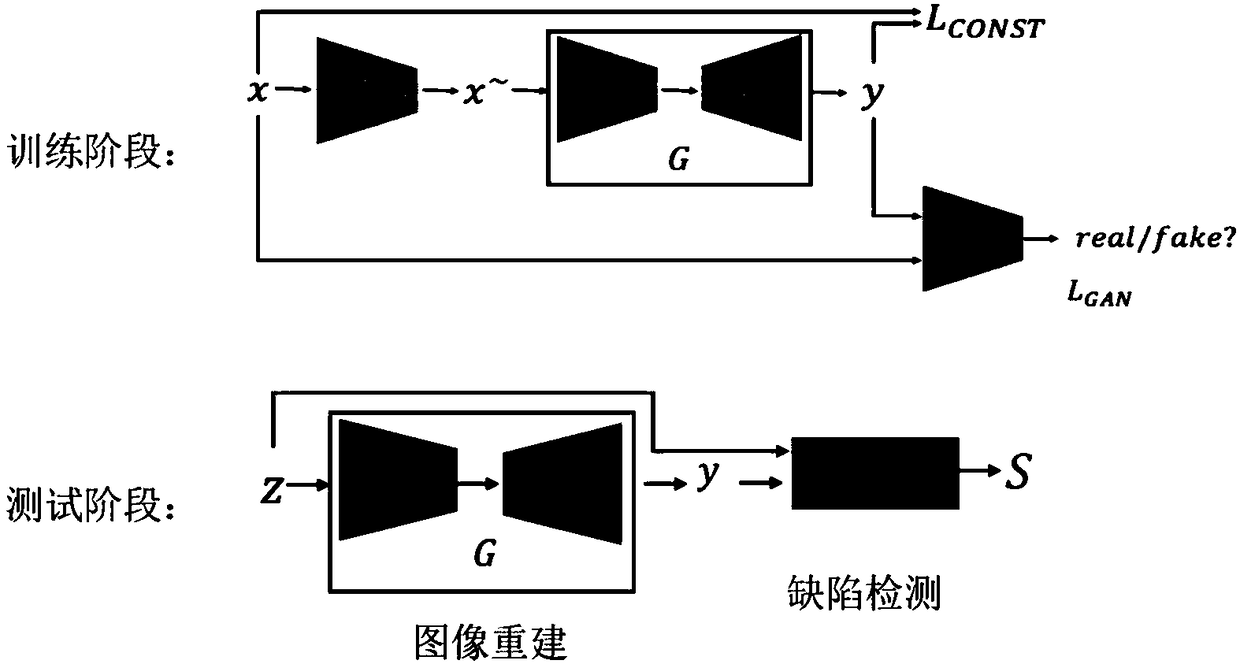

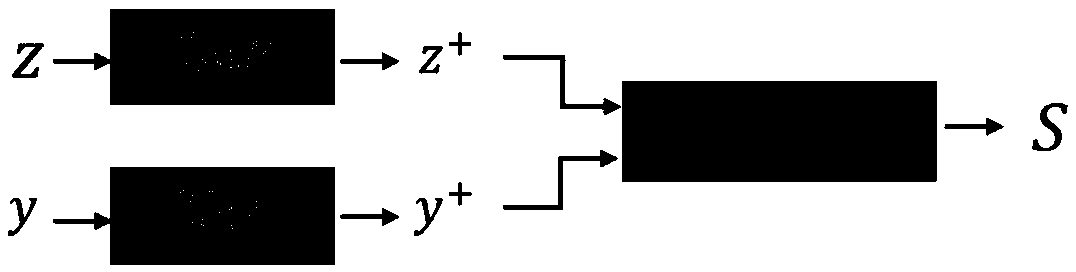

[0047] In order to solve the problems of poor robustness of traditional vision algorithms, difficult acquisition of defect samples of supervised learning algorithms and high labor cost, the present invention proposes a surface defect detection method based on positive example training, the main steps of which can be found in figure 1 , G in the figure is the self-encoder, EN and DE refer to the encoding and reconstruction of the self-encoder, and D is the discriminator of the generated confrontation network GAN. The specific implementation is described in the following description:

[0048] Image reconstruction:

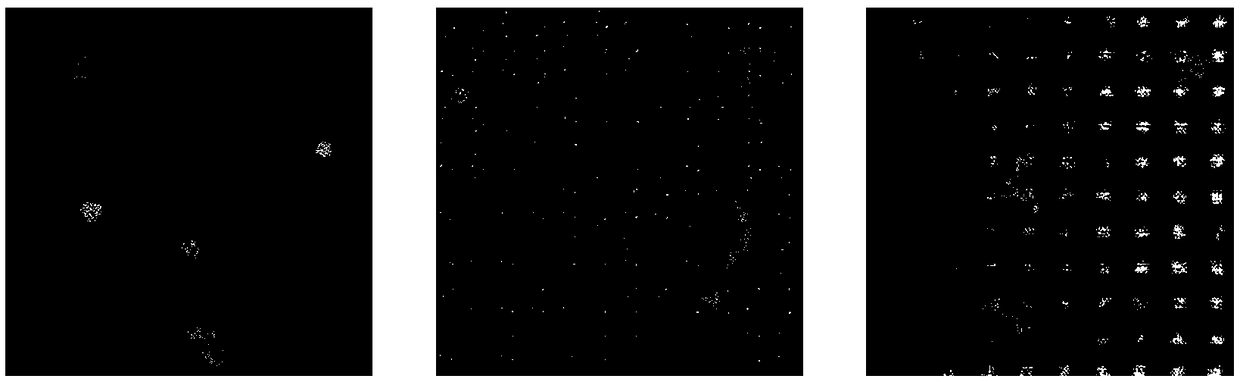

[0049] 1) Adding random artificial defects and noises to the positive image does not need to know the specific shape of the real defect. The self-encoder in the present invention only needs to restore the original image to the closest positive sample. Therefore, artificial enough random defects are pasted on the positive samples during training, and the network can ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com