Design method for three-dimensional emergency simulation disposal of gas leakage of benzene hydrogenation device

A technology of gas leakage and design method, which is applied in simulators, design optimization/simulation, simulation devices of space navigation conditions, etc. The level of training, the effect of improving practicality and operability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

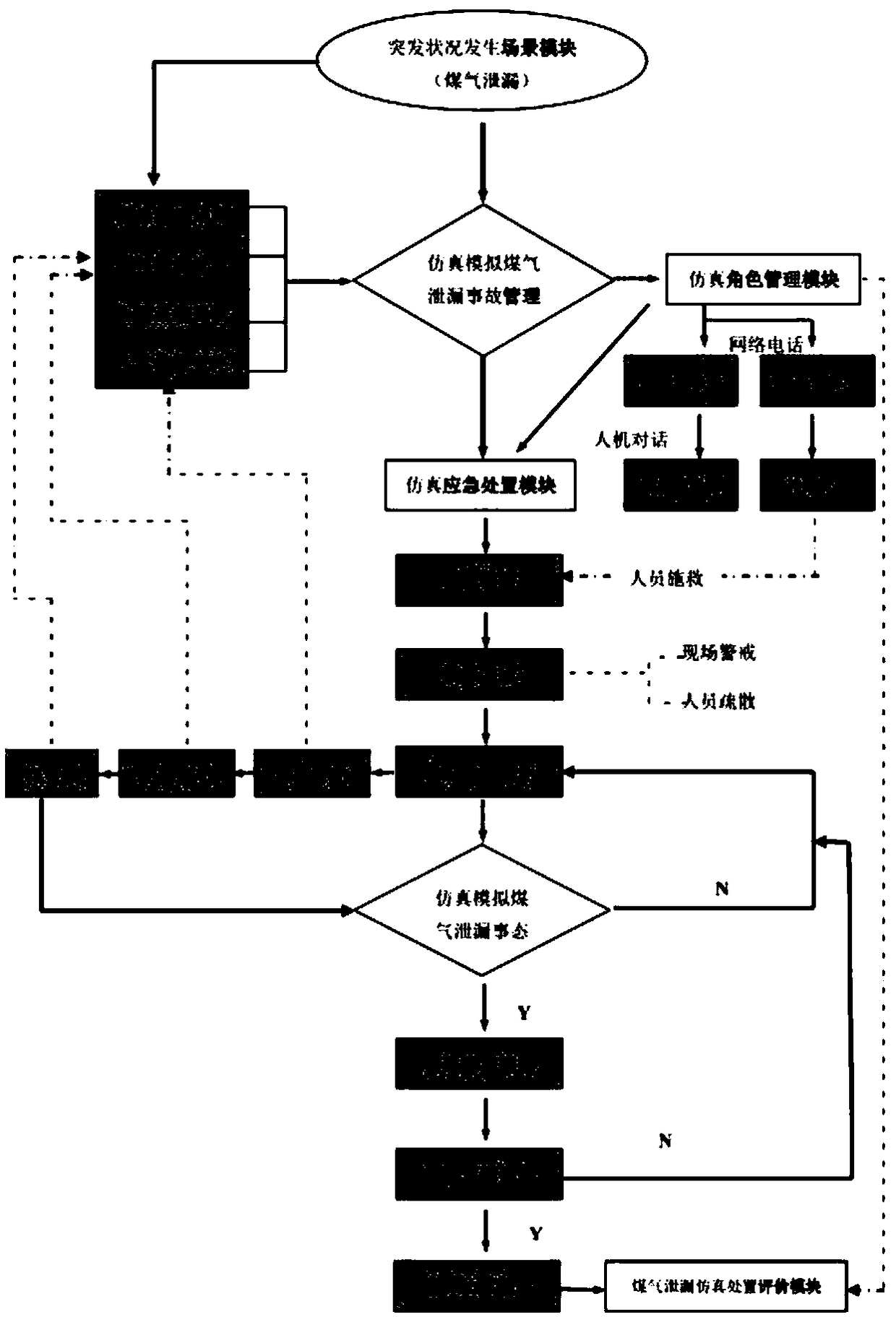

[0029] Three-dimensional emergency simulation treatment in case of gas leakage in benzene hydrogenation unit

[0030] 1) Start the 3D simulation drill client, select "gas leak emergency drill", and the simulation drill starts.

[0031] 2) Based on the accident simulation and scene module, the screen displays "toxic and flammable gas alarm system" interface, and "a certain position" appears a gas high alarm;

[0032] The screen shows that the DCS interface appears: the hydrogenation furnace gas volume 200m3 / h suddenly drops;

[0033] Changes in the opening of the gas regulating valve of the hydrogenation furnace (need to be accessed by "role");

[0034] The outlet temperature of the hydrogenation furnace drops slowly at 275°C (need to be accessed by the "role");

[0035] 3) Role selection: Set roles according to the current situation of benzene hydrogenation production, and select commanders, squad leaders, external operators, internal operators, on-site reviewers, etc. In t...

Embodiment 2

[0047] Three-dimensional emergency simulation treatment in the case of benzene hydrogenation gas leakage

[0048] 1) Start the 3D simulation drill client, select "gas leak emergency drill". The simulation exercise begins. Same as Example 1

[0049] 2) Based on the accident simulation and scene module, display in the screen: same as embodiment 1

[0050] 3) role selection: same as embodiment 1

[0051] 4) Simulate emergency shutdown operation: Based on the role module, accident simulation and scene module, field operators obtain information such as gas leakage near the heating furnace of the system's real simulation system; they also obtain instructions from the commander and squad leader (through personnel deployment in the role management module) ).

[0052] The internal operators report the danger to the branch factory and the dispatcher and request to start the corresponding emergency plan, followed by emergency shutdown and control of the process parameters of each tow...

Embodiment 3

[0058] Three-dimensional emergency simulation treatment in the case of benzene hydrogenation gas leakage and casualties

[0059] 1) Start the 3D simulation drill client, select "gas leak emergency drill". The simulation exercise begins. Same as Example 1

[0060] 2) Based on the accident simulation and scene module, display in the screen: same as embodiment 1

[0061] 3) role selection: same as embodiment 1

[0062] 4) Simulate emergency shutdown operation: Based on the role module, accident simulation and scene module, field operators obtain information such as gas leakage near the heating furnace of the system's real simulation system; they also obtain instructions from the commander and squad leader (through personnel deployment in the role management module) ).

[0063] The internal operators report the danger to the branch factory and the dispatcher and request to start the corresponding emergency plan, followed by requesting 120 rescue, broadcasting to evacuate the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com