A lithium battery recovery process

A lithium battery and process technology, applied in the field of lithium battery recycling technology, can solve the problems of low processing efficiency, impact on the recovery efficiency of lithium battery positive electrode materials, insufficient magnetic cleaning, etc., and achieve the effect of accelerating the crushing speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] In order to make it easy to understand the technical means, creative features, goals and effects achieved by the present invention, the present invention will be further explained below in conjunction with specific embodiments.

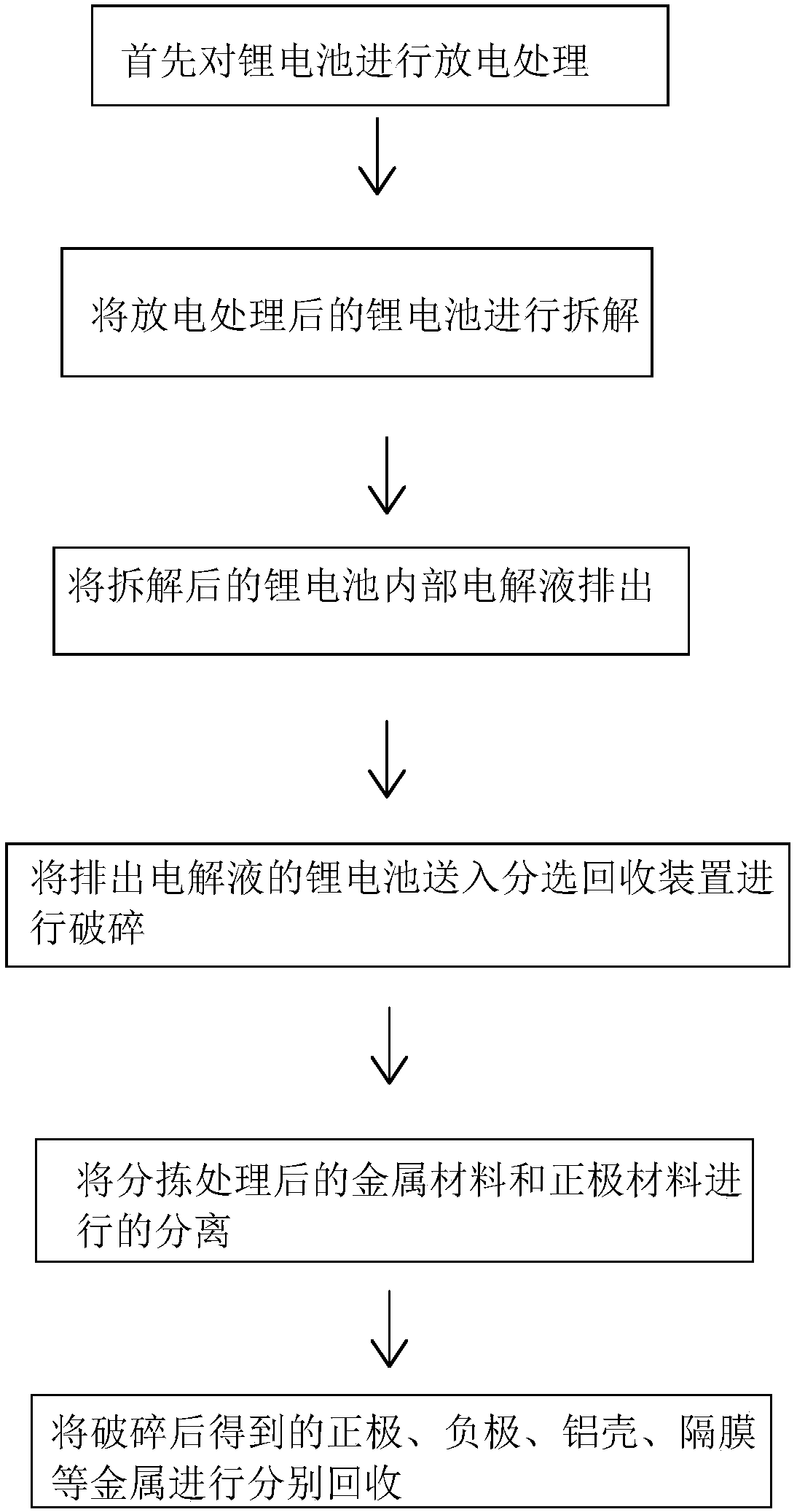

[0030] Such as Figure 1 to Figure 5 As shown, a lithium battery recycling process according to the present invention includes the following steps:

[0031] S1, first discharge the lithium battery;

[0032] S2, disassemble the lithium battery discharged in S1, and recover the disassembled shell;

[0033] S3, drain the internal electrolyte of the disassembled lithium battery in S2;

[0034] S4: Send the lithium battery discharged from the electrolyte in S3 to the sorting and recovery device for crushing;

[0035] S5: Separately recover the positive electrode, negative electrode, aluminum shell, separator and other metals obtained after crushing in S4;

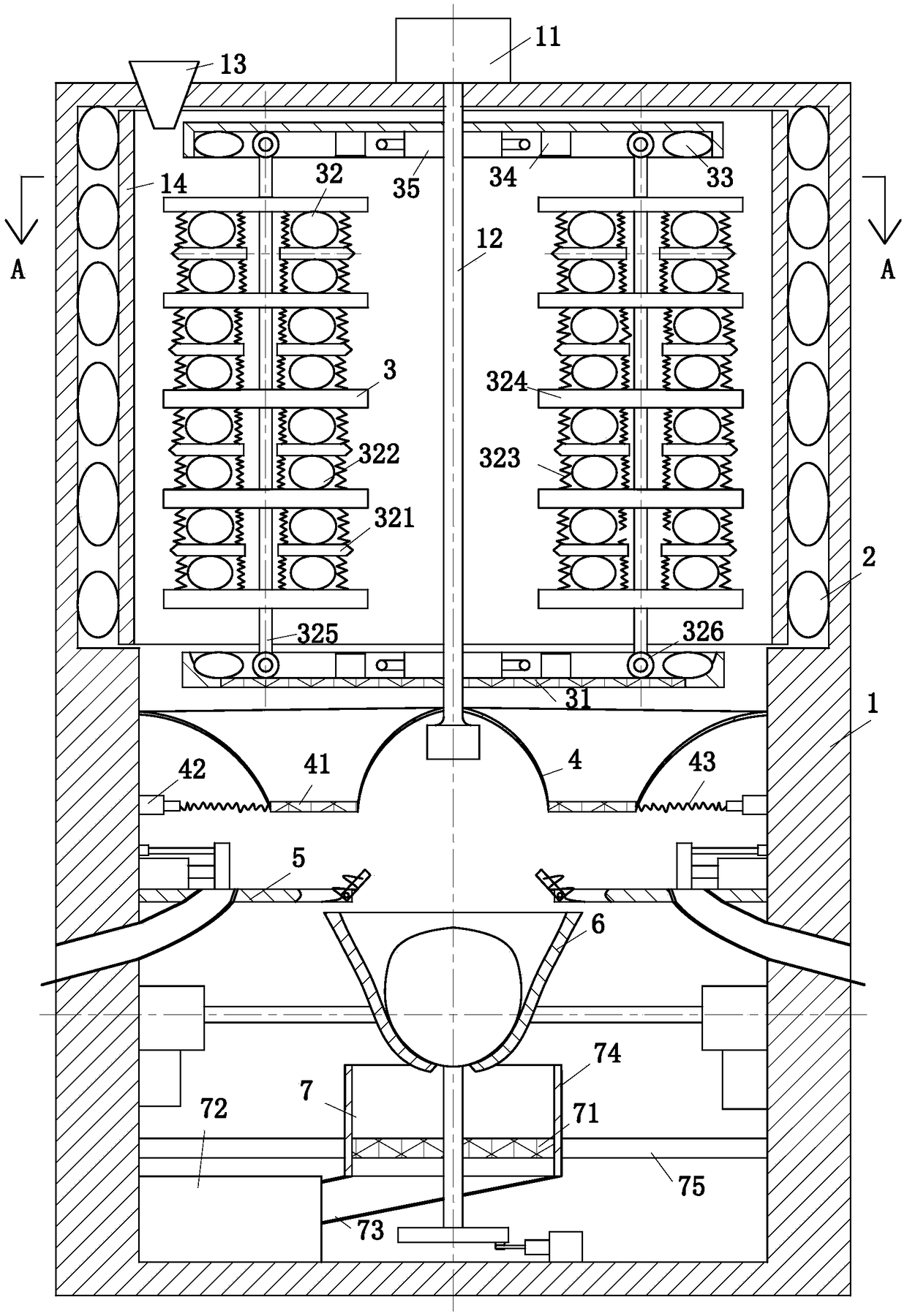

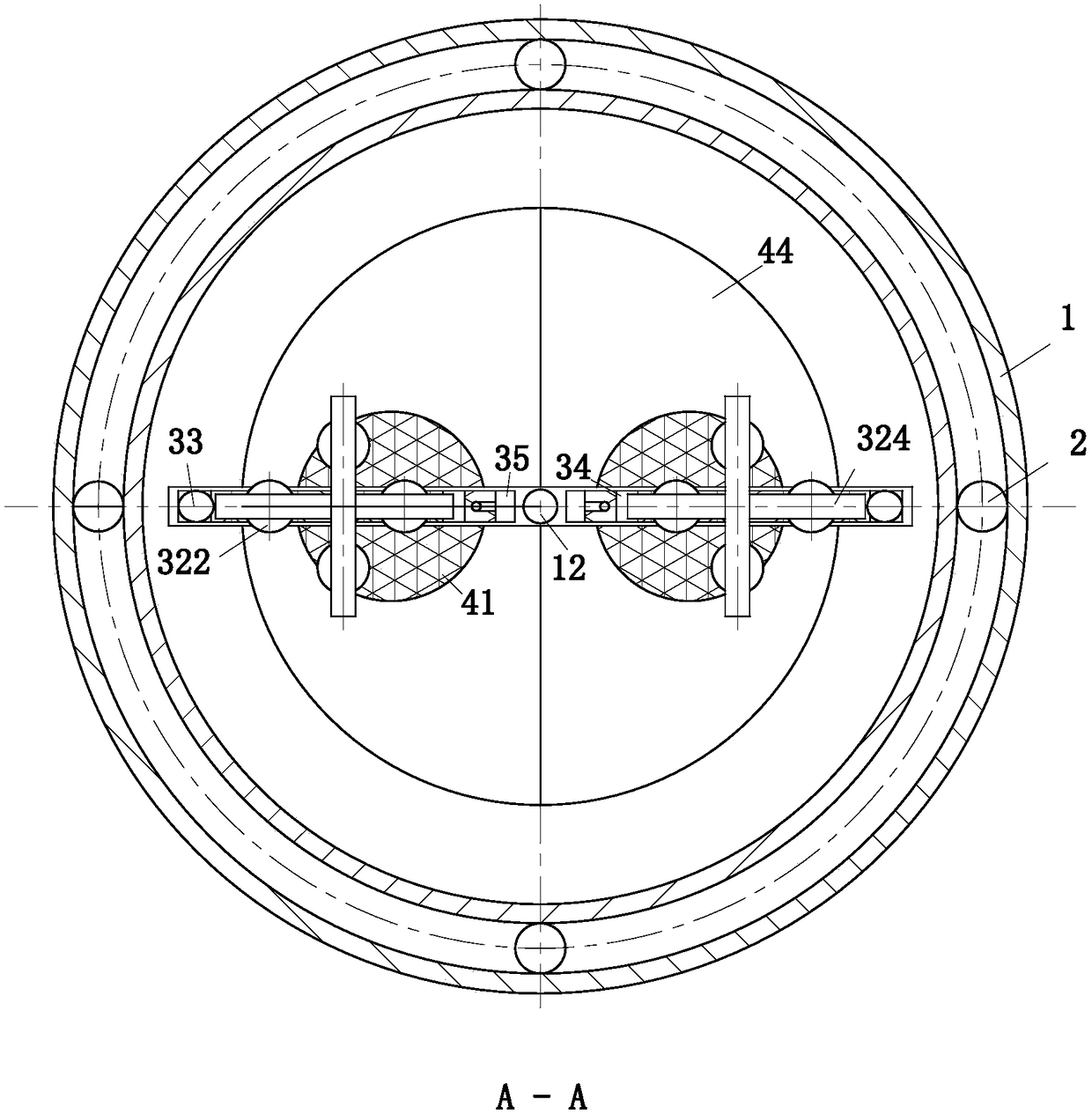

[0036] Among them, the sorting and recycling device originally includes the main body 1, the No. 1 elast...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com