Waterproof treatment method of cable net on rocket launcher

A waterproof treatment and launch vehicle technology, which is applied in the direction of dustproof/splashproof/leakproof/waterproof/fireproof connections, circuits, electrical components, etc., which can solve frequent quality problems, poor waterproof performance of cable nets due to connectors, etc. problem, to achieve the effect of material usage quantification, universal applicability, and controllable operation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention will be described in detail below in conjunction with the accompanying drawings and examples.

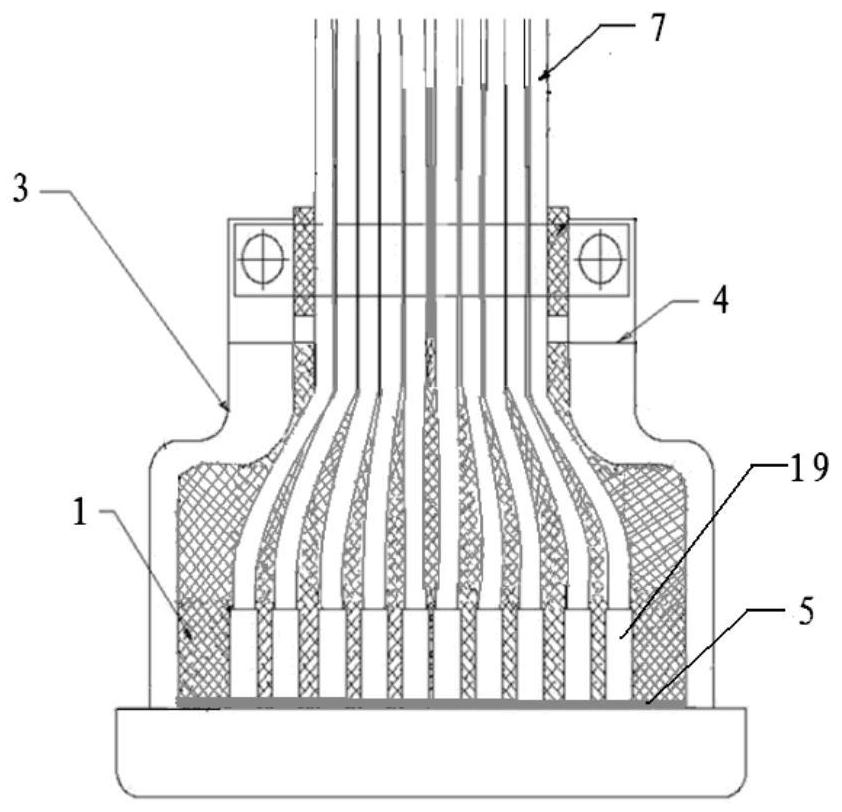

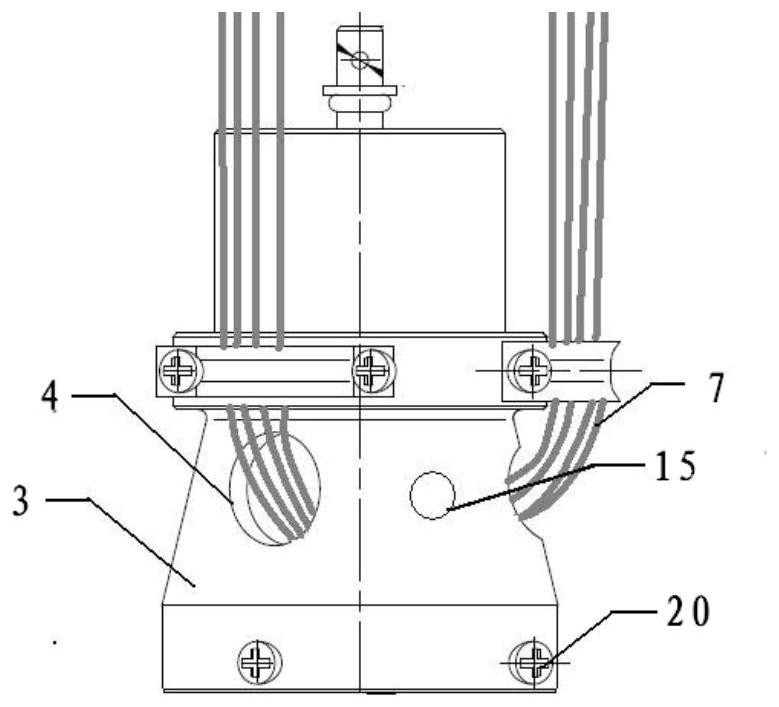

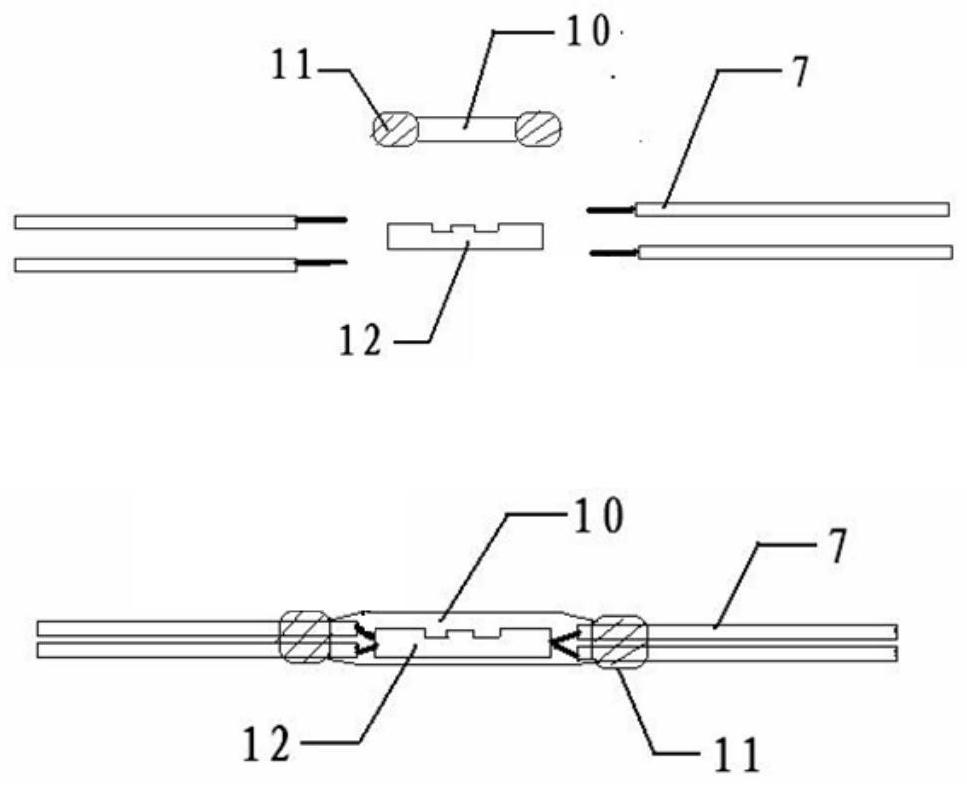

[0039] The waterproof treatment method of the cable net on the carrier rocket arrow of the present invention mainly includes the waterproof treatment of the welded electrical connector (such as figure 1 , figure 2 shown), waterproof treatment of wire contacts in the wiring harness (such as image 3 , Figure 4 shown), crimping type electrical connector waterproof treatment (such as Figure 5 shown) in three aspects. Of course, according to different engineering practices, any one or more aspects of the above-mentioned waterproof treatment can be carried out.

[0040] The above three aspects will be described in detail below in combination with examples.

[0041] 1. Waterproof treatment of welded electrical connectors

[0042] 1.1 Electrical connector pretreatment

[0043] Follow the steps below to require waterproof pretreatment for soldered elec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com