Staged start control system and method of three-stage brushless synchronous motor

A synchronous motor and starting control technology, which is applied to the control and starting devices of wound-type excitation motors, can solve the problems of difficult, complex and low-efficiency excitation, and achieve simplified starting excitation strategy, simplified starting controller7, reduced The effect of small volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The technical solutions of the present invention will be described in detail below in conjunction with the accompanying drawings.

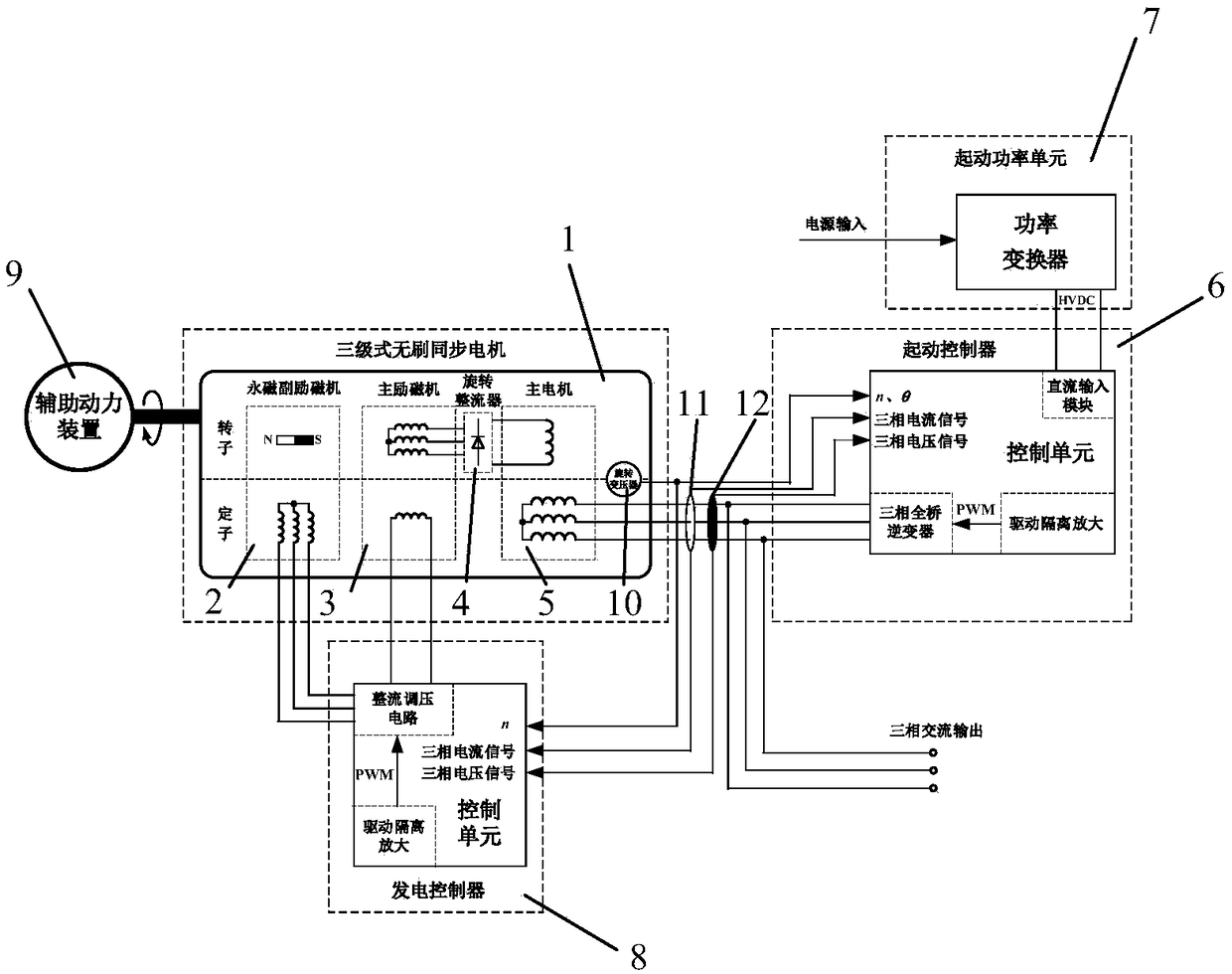

[0017] figure 1 It is a block diagram of a three-stage brushless synchronous motor staged start control system for the auxiliary power unit 9 . The starting system is composed of a three-stage brushless synchronous motor 1 , a starting controller 6 , a starting power unit 7 and a generator controller 8 . During the starting process, the starting power unit 7 converts the input power into high-voltage direct current, and inputs it into the starting controller 6 . The starting controller 6 supplies three-phase alternating current to the armature winding of the main motor 5 of the three-stage brushless synchronous motor according to the rotational speed and position information provided by the resolver 10, and the current transformer 11 and the voltage sensor 12 are responsible for returning current and voltage signals . The stator current ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com