Green tea processing device

A processing device and technology of green tea, which is applied in tea treatment before extraction, solid separation, sieving, etc., can solve problems such as time-consuming and laborious, long time for aroma enhancement, and increased wear of tea leaves, and achieve cost reduction, simple operation, and avoid browning. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The following is further described in detail through specific implementation methods:

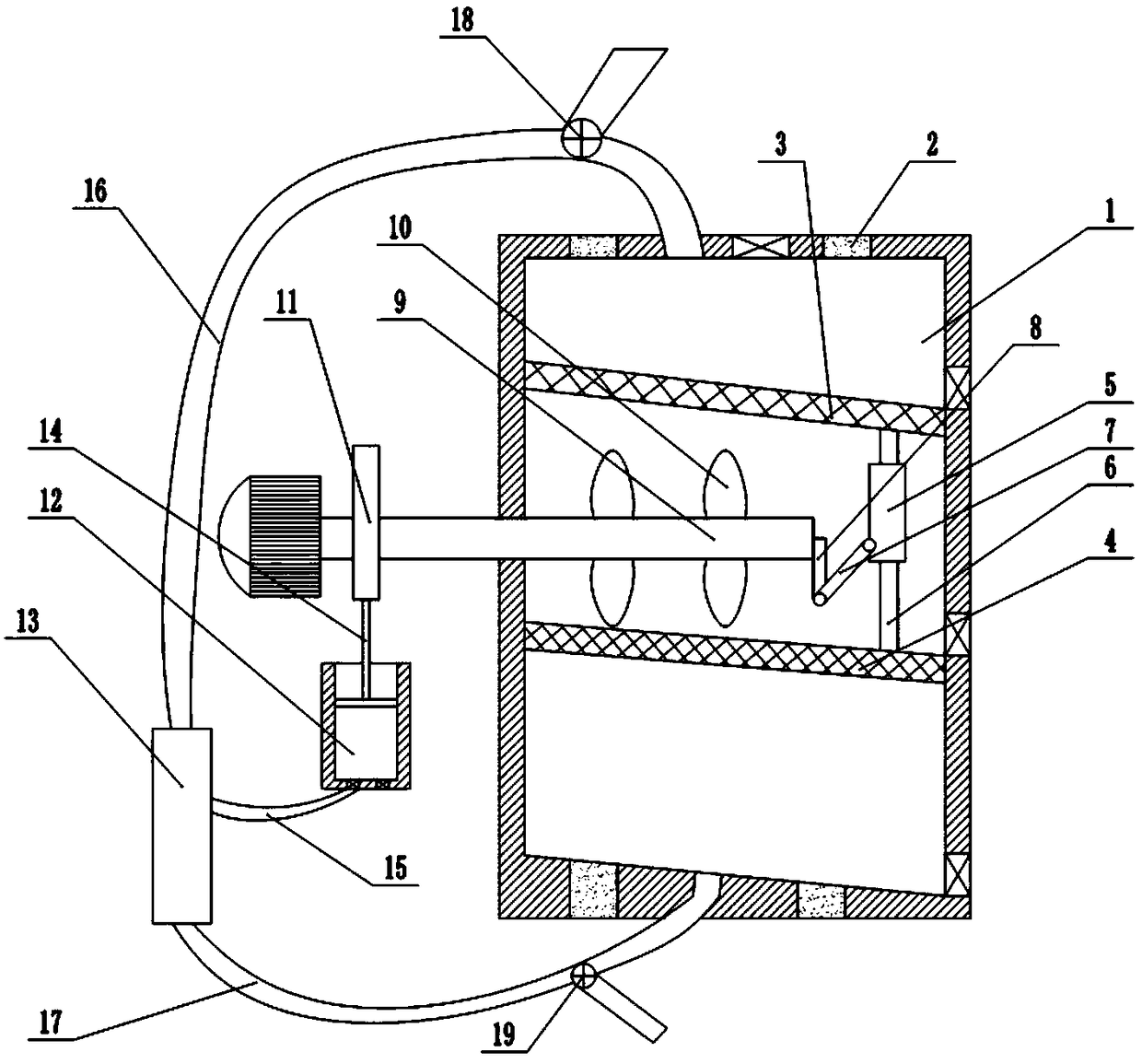

[0024] The reference signs in the drawings of the description include: processing barrel 1, through hole 2, first filter screen 3, second filter screen 4, knocking rod 5, slide rail 6, connecting rod 7, crank 8, output shaft 9, Stirring blade 10, cam 11, piston barrel 12, vortex tube 13, piston rod 14, outlet pipe 15, cold air three-way pipe 16, hot air three-way pipe 17, first solenoid valve 18, second solenoid valve 19.

[0025] Such as figure 1 As shown, the green tea processing device includes a frame on which a processing barrel 1 with both ends sealed is fixed. The top of the processing barrel 1 is provided with a feeding port, and a feeding valve is arranged in the feeding port. The upper and lower ends of the processing barrel 1 are provided with a plurality of through holes 2, and filter cloths are arranged in the through holes 2, and the gas in the processing barrel 1 can ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com