Broken wall direct drink granules

A technology of granules and wall-breaking powder, which is applied in the functions of food ingredients, food ingredients containing oligosaccharides, food science, etc., can solve the problems of inconvenient use of solid beverages, easy moisture absorption stability, poor acceptance of raw materials, etc. Achieve the effects of rapid dissolution, good stability, and full utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

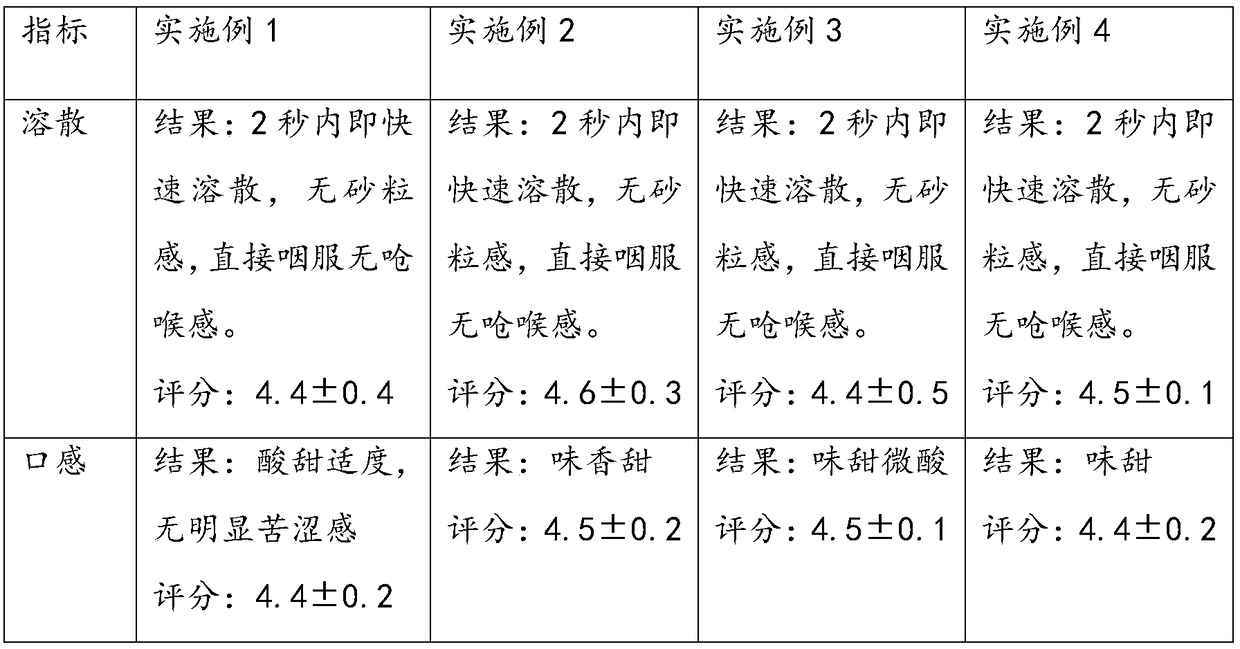

Embodiment 1

[0029] Example 1 Seabuckthorn Maca Broken Wall Direct Drinking Granules

[0030] 1.1 Take seabuckthorn, sort and remove the impurities, dry it to a moisture content below 8.0%, and sterilize it with hot steam for 3 to 10 seconds;

[0031] 1.2 Take maca, sort it, wash it quickly, dry it to a moisture content below 8.0%, and sterilize it with hot steam for 3 to 10 seconds;

[0032] 1.3 Weigh seabuckthorn and maca according to the ratio of 1:1 by weight, mix them evenly, and crush them into 75 μm wall-breaking powder by a wall-breaking grinder.

[0033] 1.4 Take the broken wall powder and glucose powder in 1.3, put them into a high-efficiency wet mixer at a weight ratio of 1:1, add an appropriate amount of 95% ethanol to moisten the soft material, granulate with a 40-mesh sieve, and dry.

[0034] 1.5 Collect 60-80 mesh particles after sieving.

Embodiment 2

[0035] Embodiment 2 Chinese yam broken wall direct drinking granule

[0036] 2.1 Take the yam, select and wash it, and then sterilize it with hot and humid steam at 121°C for 10 minutes, and dry it until the water content is below 8.0%;

[0037] 2.2 Take the Chinese yam in 2.1 and crush it into 60 μm wall-breaking powder through a wall-breaking grinder.

[0038] 2.3 Take the broken wall powder and sucrose powder in 2.2, put them into a high-efficiency wet mixer in a weight ratio of 1:6, add an appropriate amount of 95% ethanol to moisten the soft material, granulate with a 40-mesh sieve, and dry.

[0039] 2.4 After sorting and sieving, collect 60-100 mesh particles, add 1‰ of strawberry essence and mix evenly to get ready.

Embodiment 3

[0040] Example 3 Codonopsis Codonopsis Broken Wall Direct Drinking Granules

[0041] 3.1 Take Codonopsis pilosula, select, quickly wash, dry to below 8.0% moisture, and sterilize by irradiation;

[0042] 3.2 Take the Codonopsis pilosula in 3.1 and crush it to 45 μm wall-breaking powder through a wall-breaking grinder.

[0043]3.3 Take the broken wall powder and mannose oligosaccharides in 3.2, put them into a high-efficiency wet mixer in a weight ratio of 1:3, add an appropriate amount of 95% ethanol (4‰ of citric acid and 1‰ of malic acid are pre-dissolved in 95% ethanol ) after wetting the soft material, granulate with a 40-mesh sieve and dry.

[0044] 3.4 Collect 60-80 mesh particles after sorting and sieving.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com