Fabric realizing skin intimacy and heat absorption and preparation process of fabric

A preparation process and fabric technology, applied in the field of textiles, can solve the problems of poor skin-friendly properties, and achieve stable performance, good skin-friendly effect, and good smell

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

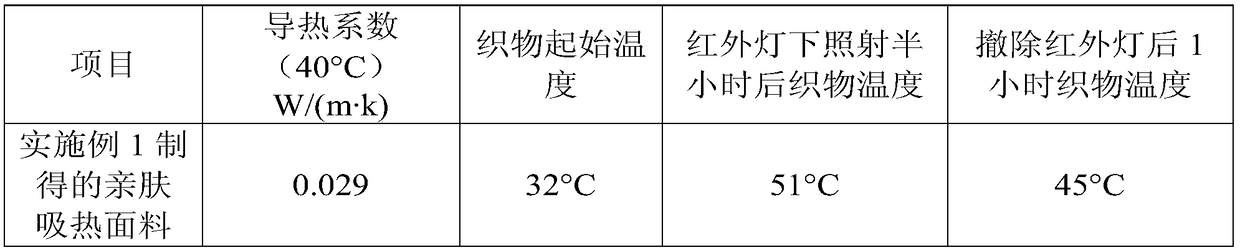

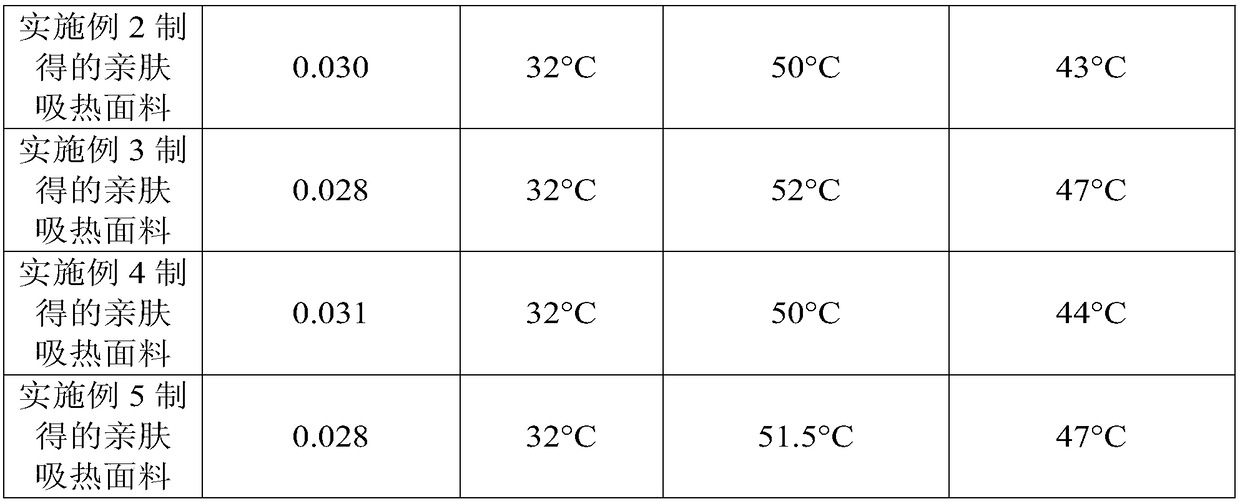

Embodiment 1

[0028] A skin-friendly heat-absorbing fabric, which is a double-layer fabric; the upper fabric is made of polypropylene fiber / bamboo fiber blended fiber; the bottom layer is made of polypropylene fiber / cotton fiber blended fiber; the polypropylene fiber / bamboo fiber blended The fineness of the mixed fiber is 12.5dtex; in the polypropylene fiber / bamboo fiber blended fiber: the weight content of the polypropylene fiber is 50%, the fineness of the polypropylene fiber is 0.62dtex, the weight content of the bamboo fiber is 50%, the fineness of the bamboo fiber The fineness is 1.21dtex; the fineness of polypropylene fiber / cotton fiber blended fiber is 10.2dtex; in the polypropylene fiber / cotton fiber blended fiber: the weight content of polypropylene fiber is 70%, the fineness of polypropylene fiber is 0.65dtex, and the cotton fiber The weight content of the cotton fiber is 20%, and the fineness of the cotton fiber is 1.25dtex; among them, the weight of the upper fabric is 75g / m 2 ;...

Embodiment 2

[0037] A skin-friendly heat-absorbing fabric, which is a double-layer fabric; the upper fabric is made of polypropylene fiber / bamboo fiber blended fiber; the bottom layer is made of polypropylene fiber / cotton fiber blended fiber; the polypropylene fiber / bamboo fiber blended The fineness of the mixed fiber is 20.2dtex; in the polypropylene fiber / bamboo fiber blended fiber: the weight content of the polypropylene fiber is 70%, the fineness of the polypropylene fiber is 0.85dtex, the weight content of the bamboo fiber is 30%, the fineness of the bamboo fiber The fineness is 1.33dtex; the fineness of polypropylene fiber / cotton fiber blended fiber is 12.2dtex; in the polypropylene fiber / cotton fiber blended fiber: the weight content of polypropylene fiber is 80%, the fineness of polypropylene fiber is 0.80dtex, and the cotton fiber The weight content of the cotton fiber is 20%, and the fineness of the cotton fiber is 1.62dtex; among them, the weight of the upper fabric is 85g / m 2 ;...

Embodiment 3

[0046] A skin-friendly heat-absorbing fabric, which is a double-layer fabric; the upper fabric is made of polypropylene fiber / bamboo fiber blended fiber; the bottom layer is made of polypropylene fiber / cotton fiber blended fiber; the polypropylene fiber / bamboo fiber blended The fineness of the mixed fiber is 16dtex; in the polypropylene fiber / bamboo fiber blended fiber: the weight content of polypropylene fiber is 60%, the fineness of polypropylene fiber is 0.73dtex, the weight content of bamboo fiber is 40%, the fineness of bamboo fiber The fineness of polypropylene fiber / cotton fiber blended fiber is 11dtex; in polypropylene fiber / cotton fiber blended fiber: the weight content of polypropylene fiber is 75%, the fineness of polypropylene fiber is 0.70dtex, and the weight of cotton fiber The content is 25%, and the fineness of cotton fiber is 1.5dtex; among them, the weight of the upper fabric is 80g / m 2 ;The weight of the bottom fabric is 90g / m 2 ;The upper fabric and the lo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fineness | aaaaa | aaaaa |

| Fineness | aaaaa | aaaaa |

| Fineness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com