Spot welding equipment for production of lithium batteries

A technology for spot welding equipment and lithium batteries, applied in welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve the problems of equipment heat dissipation that cannot be intelligently controlled, many odors or harmful substances, unfavorable working environment, etc. Simple, high heat dissipation efficiency, power saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

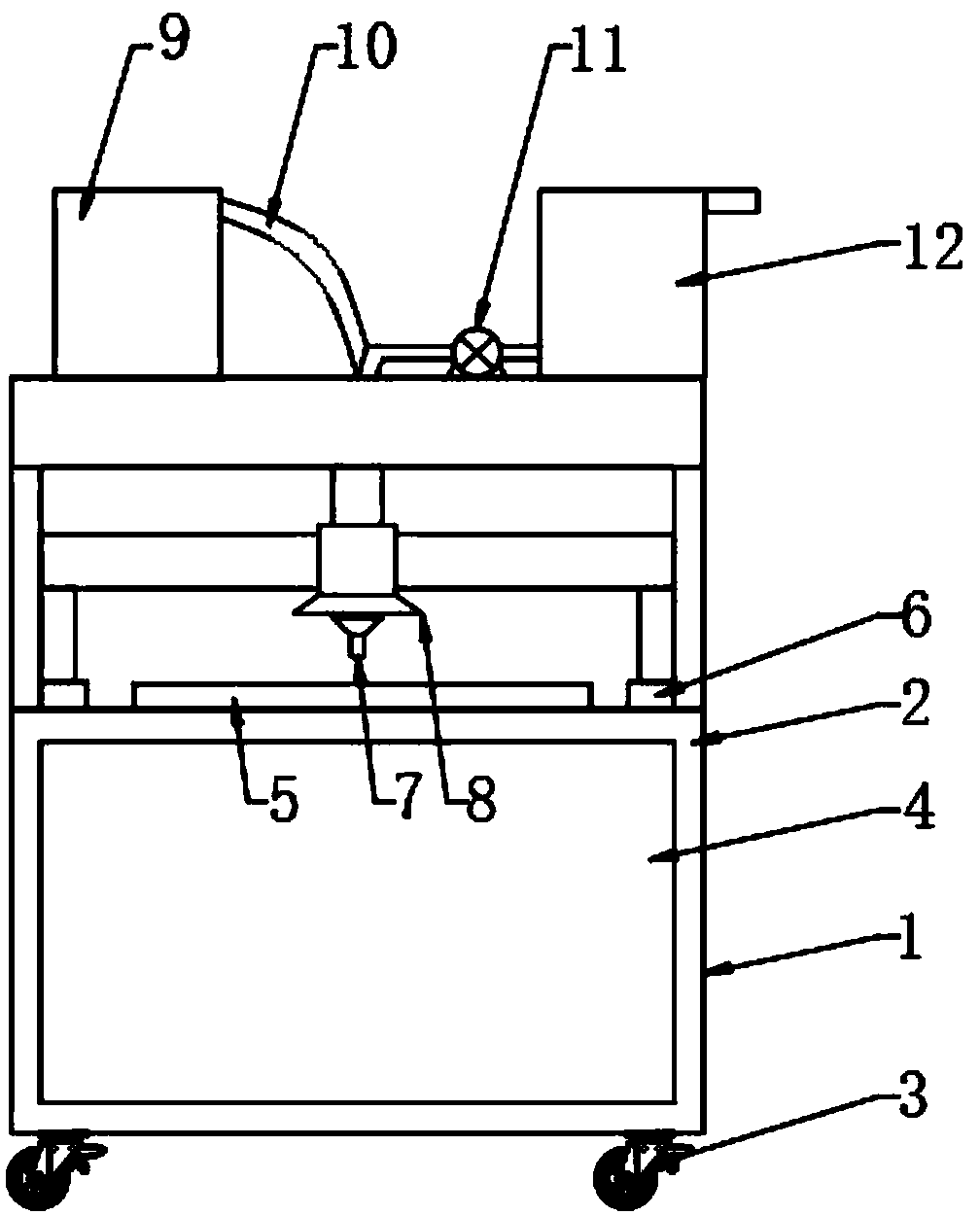

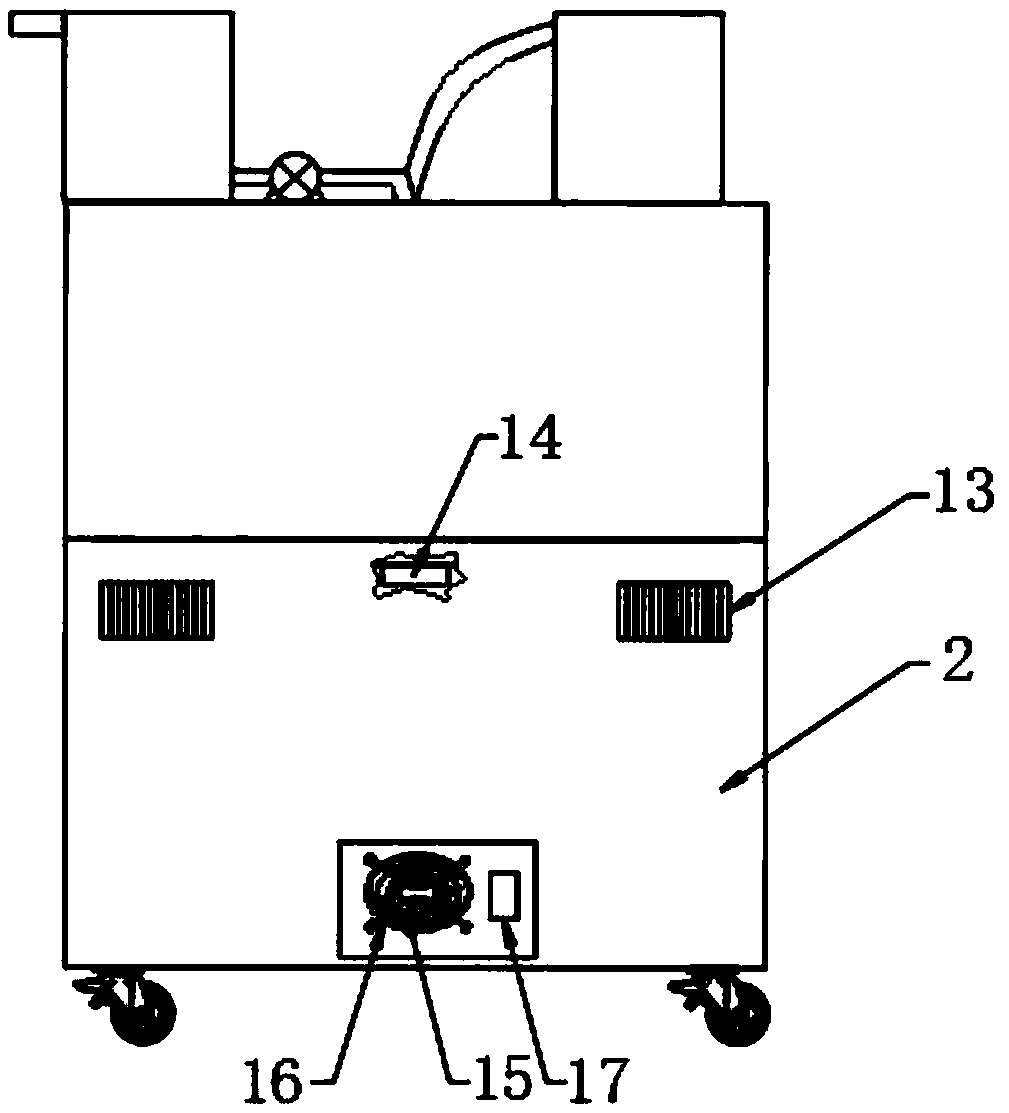

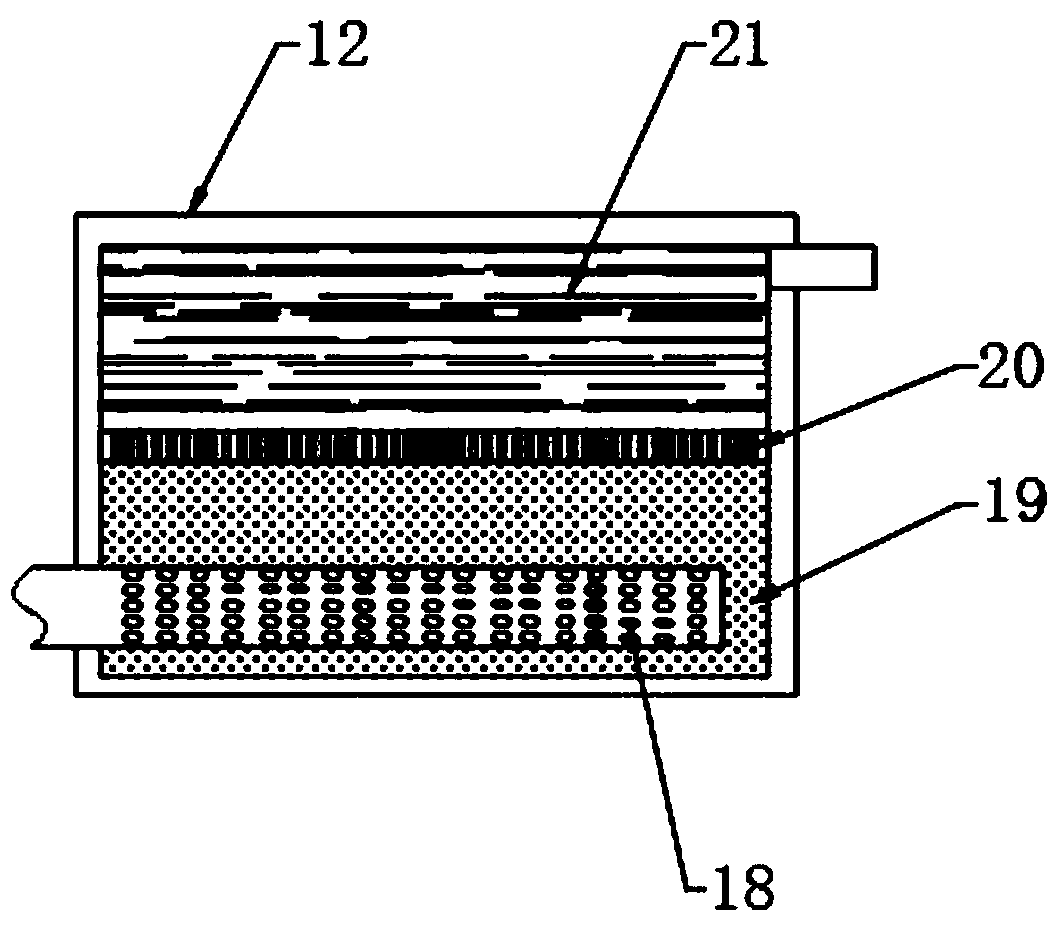

[0014] Attached below Figure 1-4 The specific implementation manner of the present invention will be described in further detail.

[0015] Depend on Figure 1-4 Given, the present invention comprises equipment body 1, and the middle part of equipment body 1 is provided with housing 2, and the four corners of housing 2 bottoms are all equipped with pulley 3, and the bottom of housing 2 side is provided with box door 4, and housing 2 one The middle part of the side is provided with a processing table, the middle part of the processing table is provided with a lithium battery fixture 5, the two sides of the lithium battery fixture 5 are provided with guide rails 6, the middle part of the guide rail 6 is equipped with a spot welding head 7, and the outer side of the spot welding head 7 is sleeved with Suction cup 8, spot welding machine host 9 is installed on the left end of shell 2 top, and the top of spot welding machine host 9 left side is connected with spot welding head 7 b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com