Sulfasalazine Tablet Mold

A sulfasalazine and mold technology, which is applied in the field of sulfasalazine tableting, sulfasalazine tableting device, and sulfasalazine tableting molds, can solve the problems of higher price, lower cost, disadvantage and the like, Achieve the effect of stable weight, cost reduction and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0074] Embodiment 1, this embodiment is a mold for making sulfasalazine tablets.

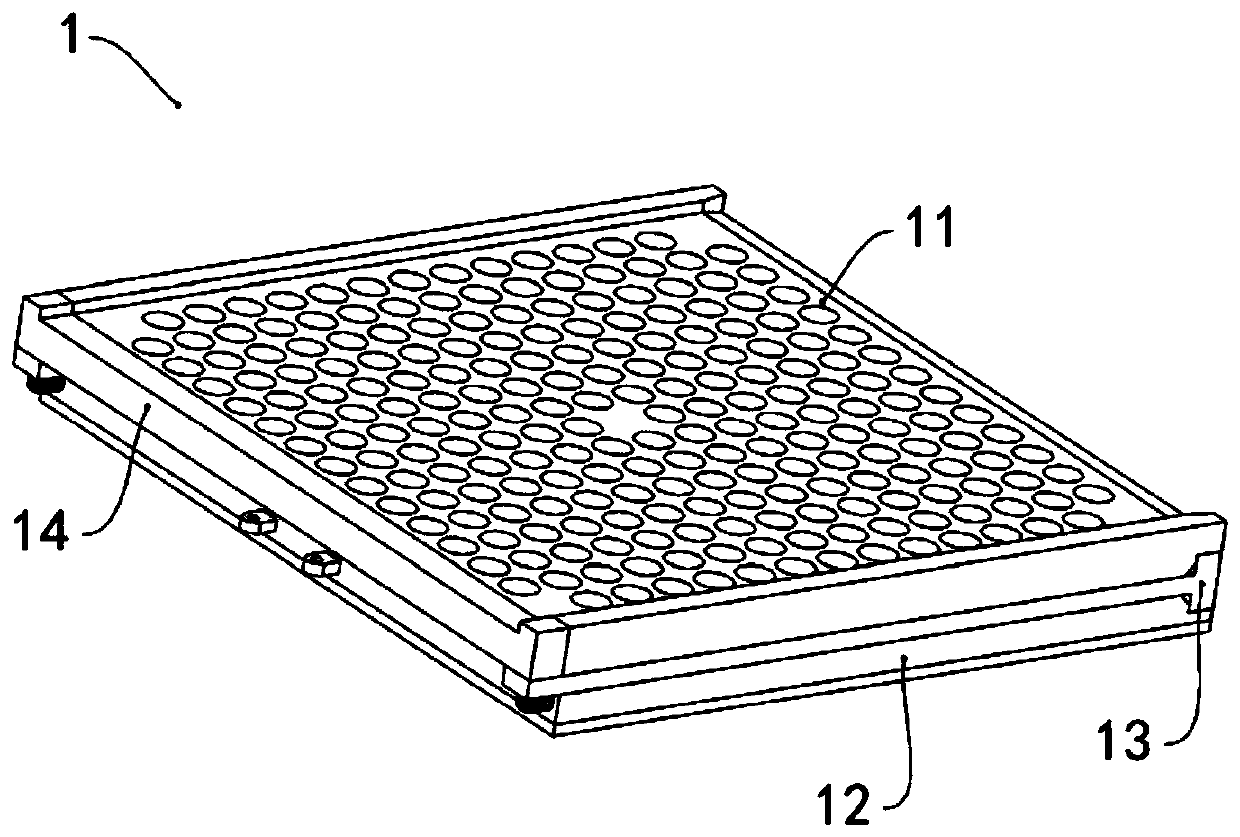

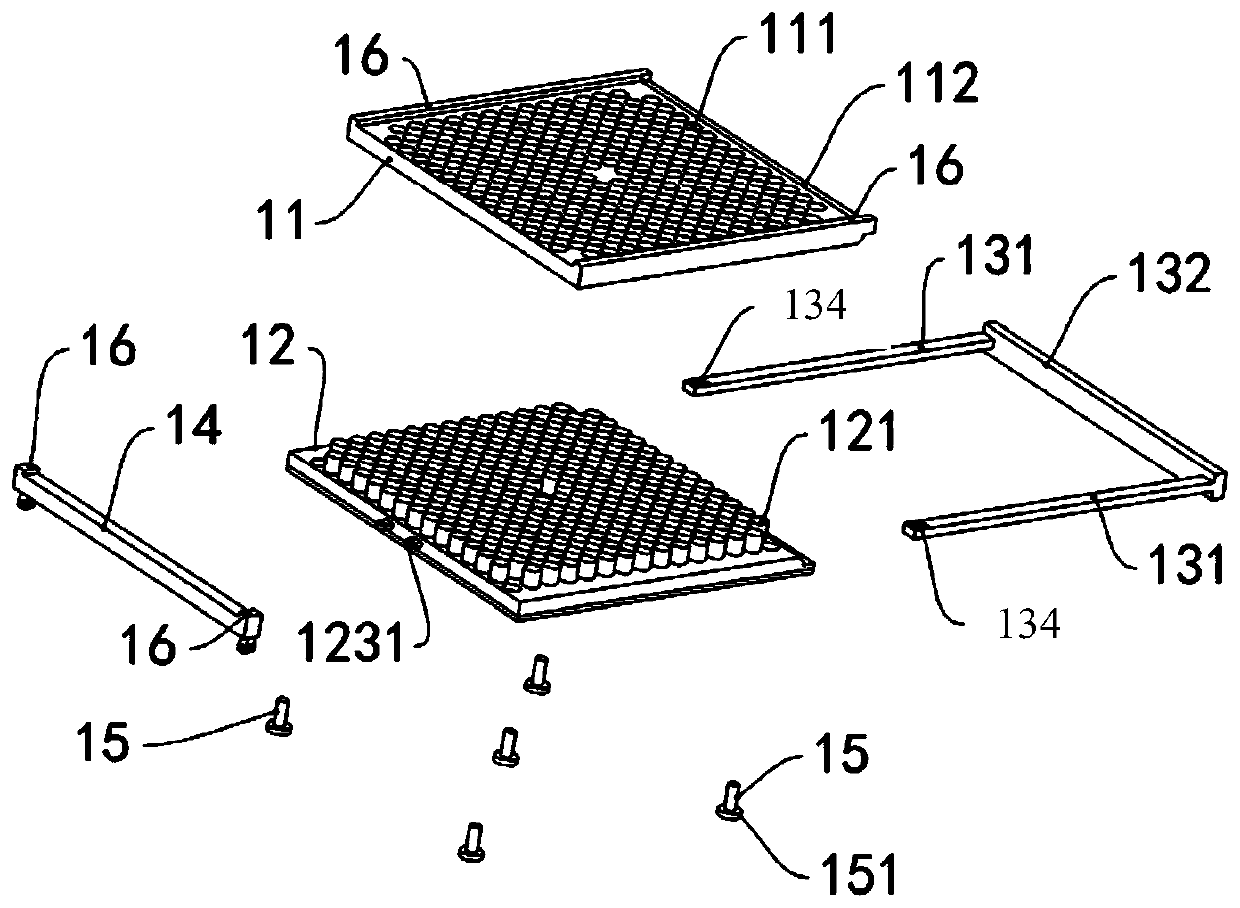

[0075] see Figure 1-Figure 9 The tablet-making mold of sulfasalazine in this embodiment includes a tablet-making mold 1 , and the tablet-making mold 1 includes an upper mold 11 , a lower mold 12 and a stopper 13 .

[0076] The upper mold 11 is provided with a penetrating tablet-making chamber 111 , and the lower mold 12 is provided with a tablet-making jack post 121 , and the tablet-making jack post 121 is inserted into the tablet-making chamber 111 snugly. Usually, the cross-section of the film-making chamber 111 and the cross-sectional shape of the film-making push column 121 are the same and are circular. The section of the film chamber 111 and the section of the film-making top column 121 are square, triangular or the like. Usually, the upper mold 11 and the lower mold 12 are made of medical stainless steel or medical ABS.

[0077] The limiting member 13 includes a limiting bar 131 , the...

Embodiment 2

[0086] Embodiment 2, this embodiment is a tablet-making device for sulfasalazine.

[0087] see Figure 10-Figure 15 , The sulfasalazine tablet-making device of this embodiment includes a tablet-making device 2 , and the tablet-making device 2 includes a transport unit 21 ; the transport unit 21 includes a transport device 211 . The conveying device 211 is usually a power belt, and may also be a linear conveying device such as a power chain or a power chain plate. Usually, the conveying part 21 further includes a frame 212 fixedly connected with the conveying device 211 for supporting the conveying device 211 .

[0088] The tablet making device 2 also includes a coating machine 22 fixedly arranged above the conveying device 211 . Usually, the coater 22 is a conventional roller coater [in the accompanying drawings, the details of the coater 22 are drawn], such as the DCM-36 coater of Nanjing Xiante Automation Equipment Co., Ltd., of course It can be a coating machine of other...

Embodiment 3

[0102] Embodiment 3, this embodiment is a method for preparing tablets of sulfasalazine.

[0103] Sulfasalazine tablet preparation method, comprises the following steps:

[0104] S1, mixing and stirring sulfasalazine powder and water to make sulfasalazine ointment 3. In the sulfasalazine powder, one or more of conventional disintegrants (such as starch, etc.), lubricants, and glidants (such as talc powder, micronized silica gel, hydrogenated vegetable oil, etc.) are usually added. Mixing, stirring is usually done in a conventional blender. Sulfasalazine ointment 3 usually determines the appropriate penetration through experiments to facilitate application.

[0105] S2, coating the sulfasalazine ointment 3 on the tablet-making mold 1 to obtain the tablet-making mold 1 coated with the sulfasalazine ointment 3 . The coating of the sulfasalazine ointment 3 is usually completed on the above-mentioned tablet making device 2 .

[0106] In S2, a step S21 of extruding the tablet-ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com