Large-capacity liquid aseptic packaging composite film

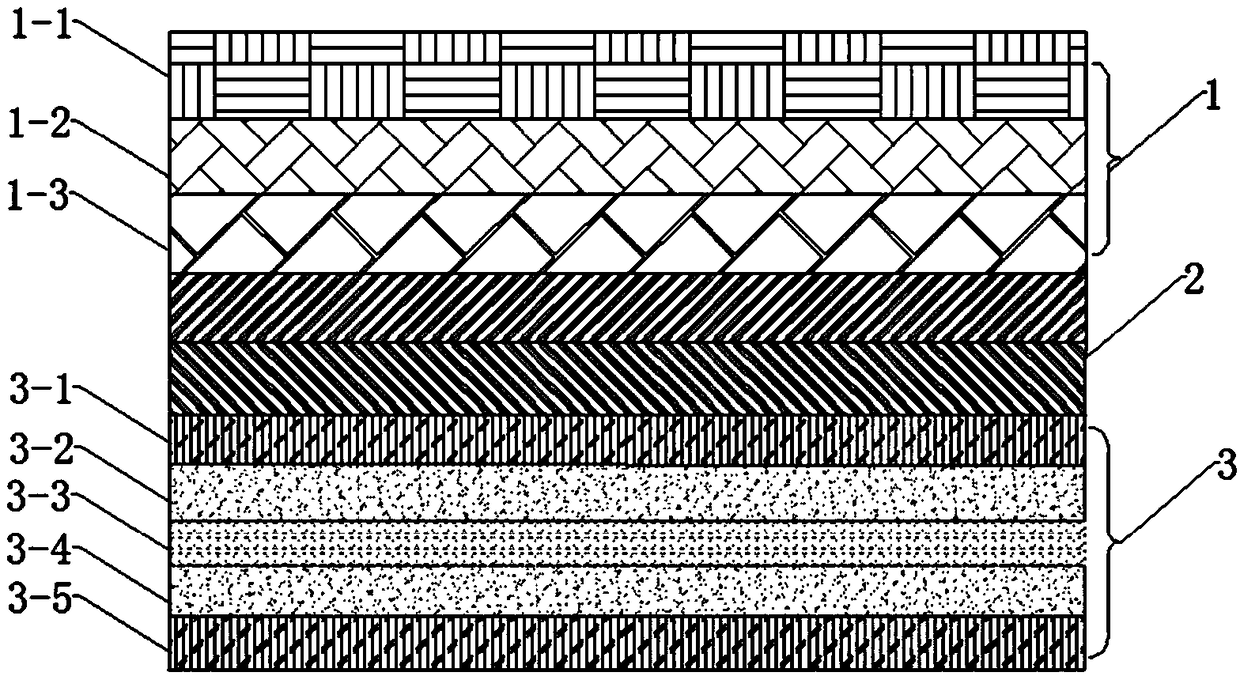

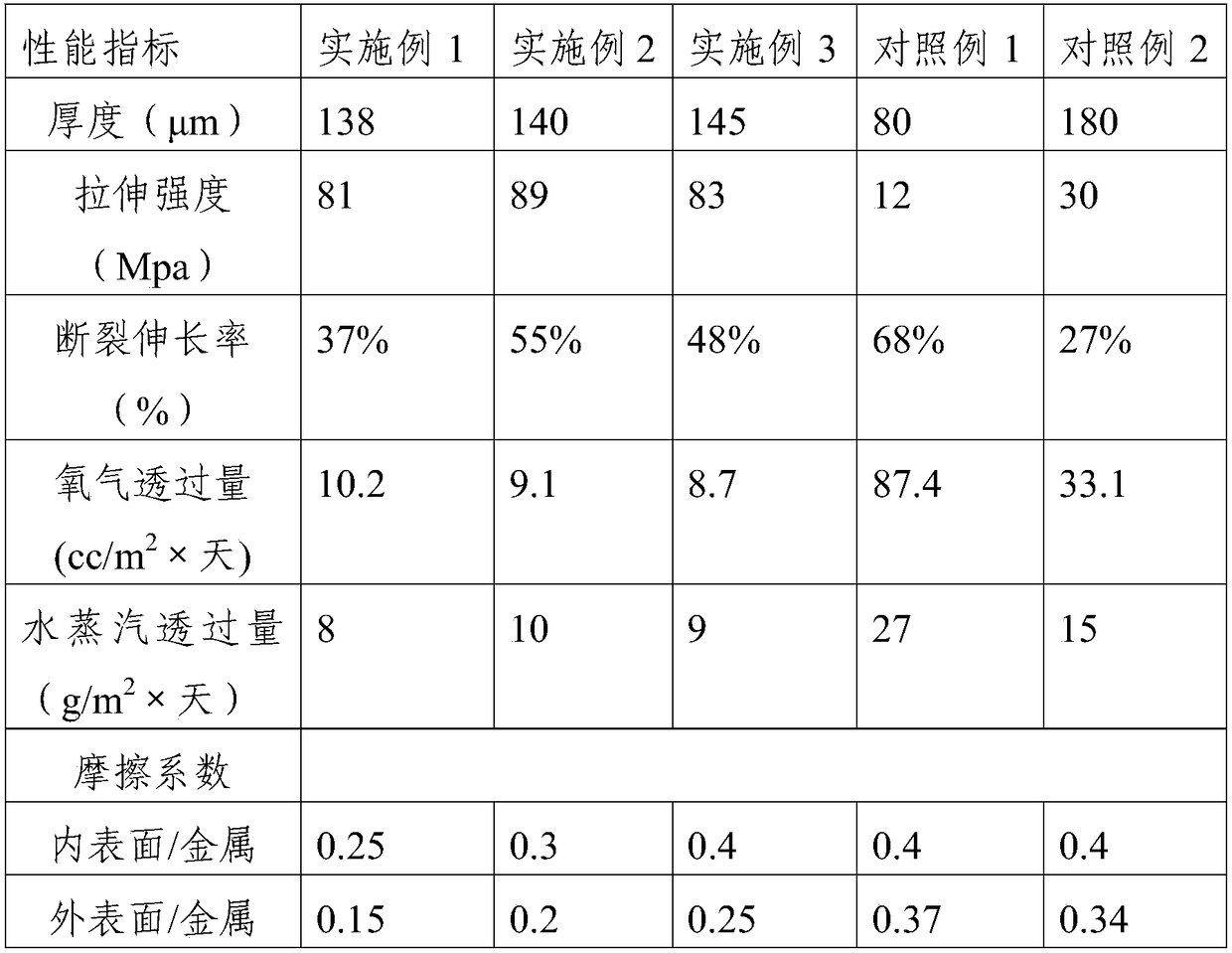

A composite film, high-capacity technology, applied in the field of packaging materials, can solve the problems of inability to meet high drop strength composite film pinholes, inability to meet large-capacity liquid packaging, and inability to meet the requirements of sterilization, etc., to achieve good anti-drop performance, Stable coefficient of friction and excellent rubbing resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] The middle film layer and the composite film layer of the asymmetric PE blown film layer are made of metallocene resin and low-density polyethylene, the addition amount of metallocene resin is 80g, the addition amount of low-density polyethylene is 15g, and the addition amount of anti-sticking agent is 2g, the amount of slip agent added is 3g, and the film-forming temperature of the asymmetric PE blown film layer is 165°C.

[0027] Asymmetric PE blown film layer and double-layer stretched nylon composite layer, between double-layer stretched nylon composite layer, and between double-layer stretched nylon composite layer and symmetrical PE co-extruded film layer through two-component polyurethane adhesive It is compounded by dry compounding method, and the amount of glue on the dry basis is 4g / m2 2 .

[0028] The symmetrical PE co-extruded film layer includes a PE film layer, an adhesive layer, a nylon film layer, an adhesive layer and a PE film layer arranged in sequen...

Embodiment 2

[0030] The middle film layer and the composite film layer of the asymmetric PE blown film layer are made of metallocene resin and low-density polyethylene, the addition amount of metallocene resin is 90g, the addition amount of low-density polyethylene is 5g, and the addition amount of anti-sticking agent is 2g, the amount of slip agent added is 3g, and the film-forming temperature of the asymmetric PE blown film layer is 180°C.

[0031]Asymmetric PE blown film layer and double-layer stretched nylon composite layer, between double-layer stretched nylon composite layer, and between double-layer stretched nylon composite layer and symmetrical PE co-extruded film layer through two-component polyurethane adhesive It is compounded by dry compounding method, and the amount of glue on the dry basis is 4.5g / m2 2 .

[0032] The symmetrical PE co-extruded film layer includes a PE film layer, an adhesive layer, a nylon film layer, an adhesive layer and a PE film layer arranged in sequen...

Embodiment 3

[0034] The middle film layer and the composite film layer of the asymmetric PE blown film layer are made of metallocene resin and low-density polyethylene, the addition amount of metallocene resin is 85g, the addition amount of low-density polyethylene is 10g, and the addition amount of anti-sticking agent is 2g, the amount of slip agent added is 3g, and the film-forming temperature of the asymmetric PE blown film layer is 180°C.

[0035] Asymmetric PE blown film layer and double-layer stretched nylon composite layer, between double-layer stretched nylon composite layer, and between double-layer stretched nylon composite layer and symmetrical PE co-extruded film layer through two-component polyurethane adhesive It is compounded by dry compounding method, and the amount of glue on the dry basis is 5g / m2 2 .

[0036] The symmetrical PE co-extruded film layer includes a PE film layer, an adhesive layer, a nylon film layer, an adhesive layer and a PE film layer arranged in sequen...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Melt index | aaaaa | aaaaa |

| Melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com