Power system of lifting device and control method thereof

A lifting device, power system technology, applied in the direction of lifting device, fluid pressure actuation system components, pump device, etc., can solve the problem of low motor energy recovery efficiency, and achieve high driving efficiency, high driving efficiency and high power generation efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

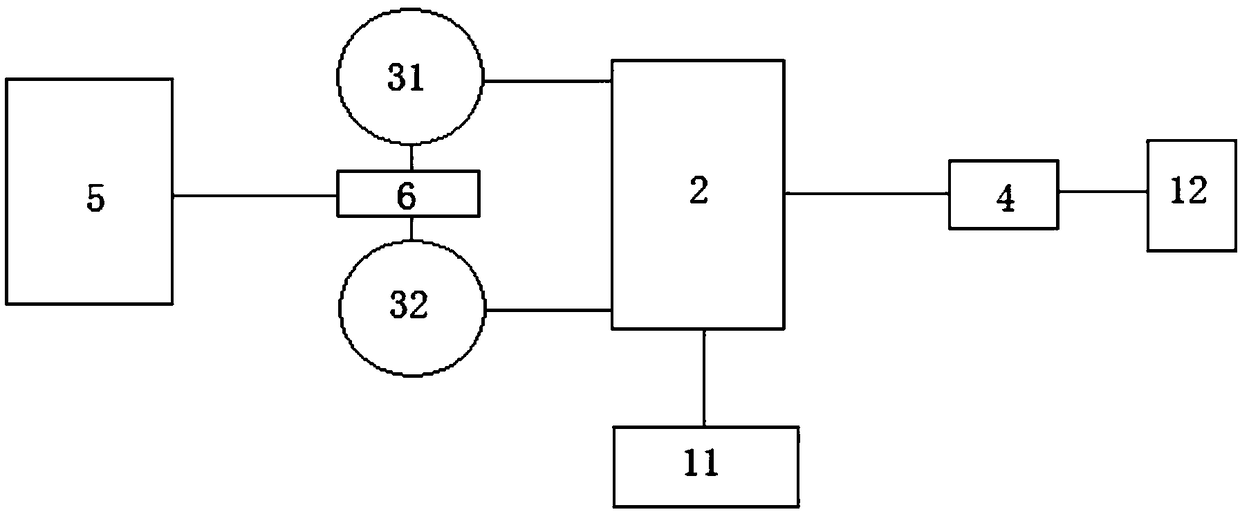

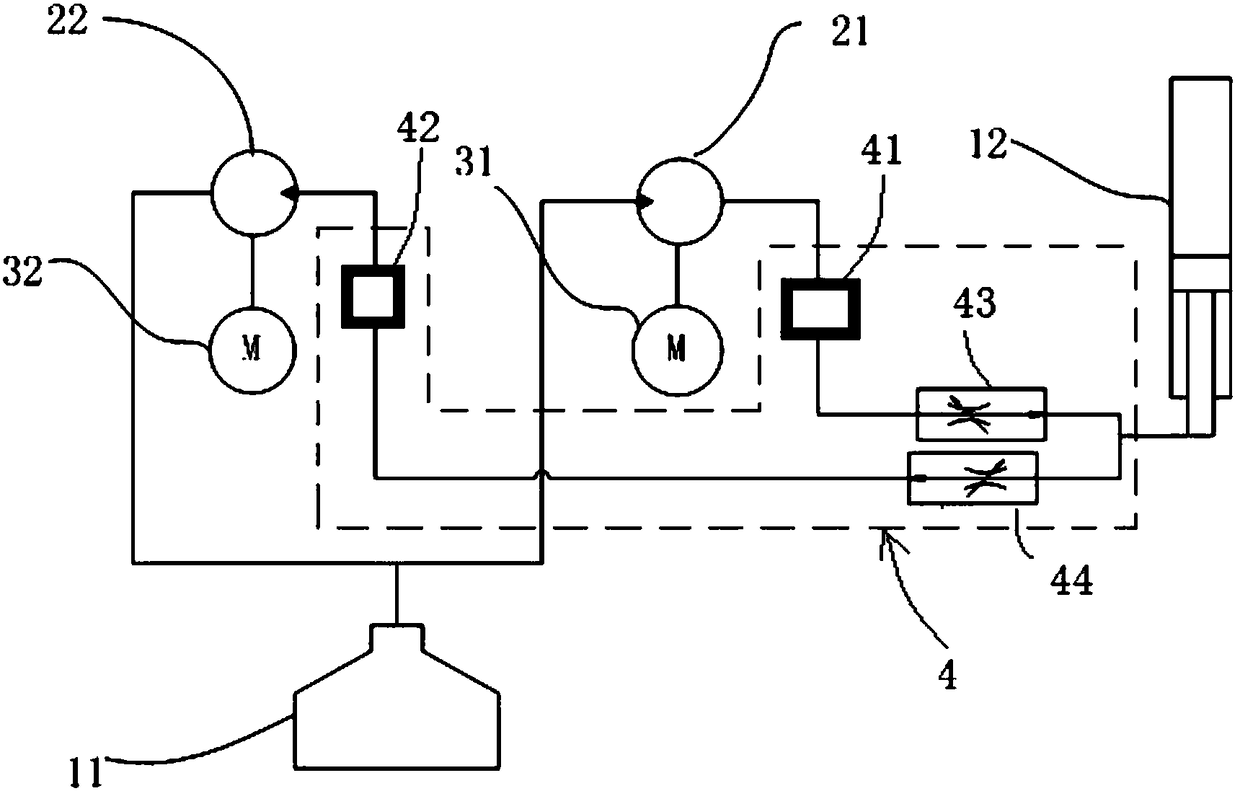

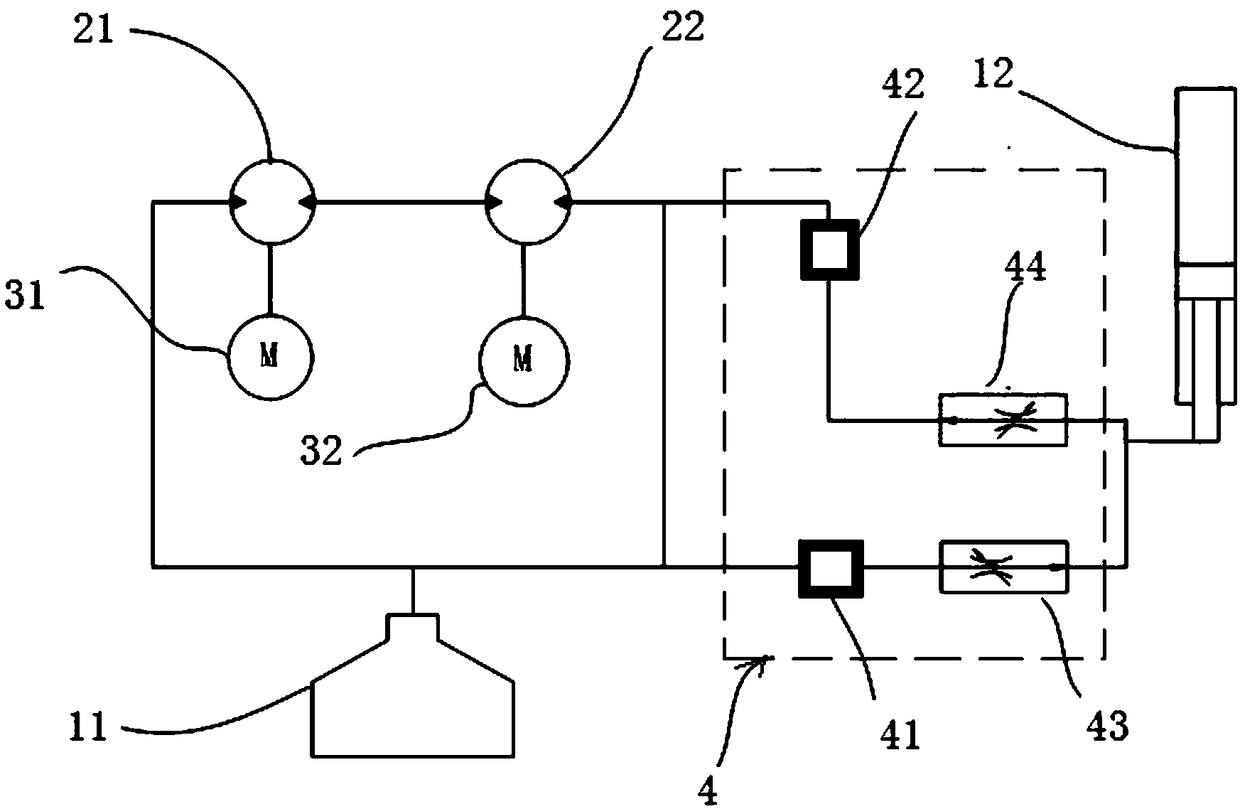

[0045] This embodiment provides a lifting device power system, such as figure 1 As shown, the lifting device power system drives a lifting device to rise and fall, and the lifting device power system includes a hydraulic cylinder 12, a liquid delivery system 4, a battery system 5, a motor control unit 6, a first motor 31, a second motor 32. The hydraulic pump system 2 and the liquid storage tank 11, wherein: when the lifting device rises, the battery system 5 supplies power to the first motor 31 through the motor control unit 6, and the first motor 31 drives the The hydraulic pump system 2 rotates, the hydraulic pump system 2 draws fluid from the reservoir 11 and supplies it to the fluid delivery system 4 which supplies the fluid to the hydraulic cylinder 12 to increase the pressure of the liquid in the hydraulic cylinder 12, and the hydraulic cylinder 12 converts hydraulic energy into mechanical energy to drive the lifting device to rise; when the lifting device descends, th...

Embodiment 2

[0064] This embodiment provides a control method for the power system of the lifting device, including: figure 1 As shown, a lifting device is driven up and down by the power system of the lifting device, wherein: when the lifting device rises, the battery system 5 supplies power to the first motor 31 through the motor control unit 6, and the first motor 31 drives the hydraulic pump The system 2 rotates, the hydraulic pump system 2 draws fluid from the reservoir 11, and supplies it to the fluid delivery system 4, which supplies the fluid to the hydraulic cylinder 12, so that the hydraulic cylinder 12 The pressure of the liquid in the lifting device rises, and the hydraulic cylinder 12 converts the hydraulic energy into mechanical energy, driving the lifting device to rise; when the lifting device descends, the mechanical energy of the power system of the lifting device is converted into hydraulic energy, and the hydraulic pressure The liquid in the cylinder 12 automatically f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com