A kind of float glass tin stripping liquid and surface tin stripping method

A float glass and tin stripping technology, which is applied in the field of tin layer tin stripping on the surface of float glass, can solve the problems of cumbersome operation process, complex process flow, high cost, etc., and achieve uniform distribution of components, low erosivity, and easy operation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

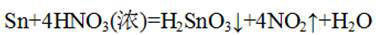

Method used

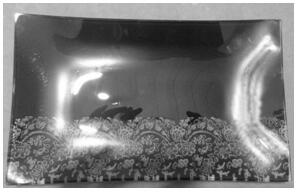

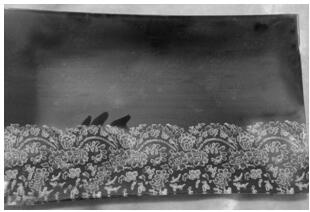

Image

Examples

Embodiment 1

[0025] Take 1000kg of 85wt% nitric acid aqueous solution, 120kg of ferric nitrate and 31kg of stabilizer to prepare tin stripping solution. Among them, the stabilizer is composed of tin chloride, diethyltriaminepentaacetic acid (DTPA), EDTMP (ethylenediaminetetramethylenephosphonic acid) and sodium nitrate, based on 100% of the stabilizer, each component in the stabilizer Content (wt%): tin chloride 12.7%, diethyltriaminepentaacetic acid (DTPA) 10.6%, EDTMP (ethylenediaminetetramethylenephosphonic acid) 23.6%, sodium nitrate 53.1%.

[0026] Add the above ferric nitrate, tin chloride and sodium nitrate into the nitric acid aqueous solution, mix evenly, then add DTPA and EDTMP, mix evenly, and obtain the tin stripping solution.

Embodiment 2

[0028] Take 1000kg of 88wt% nitric acid aqueous solution, 160kg of ferric nitrate and 42kg of stabilizer to prepare tin stripping solution. Wherein, stabilizer is with embodiment 1.

[0029] Add the above ferric nitrate, tin chloride and sodium nitrate into the nitric acid aqueous solution, mix evenly, then add DTPA and EDTMP, mix evenly, and obtain the tin stripping solution.

Embodiment 3

[0031] Take 1000kg of 86wt% nitric acid aqueous solution, 150kg of ferric nitrate and 10kg of stabilizer to prepare tin stripping solution. Wherein, stabilizer is with embodiment 1.

[0032] Add the above ferric nitrate, tin chloride and sodium nitrate into the nitric acid aqueous solution, mix evenly, then add DTPA and EDTMP, mix evenly, and obtain the tin stripping solution.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com