An ultra-high precision pressure control device

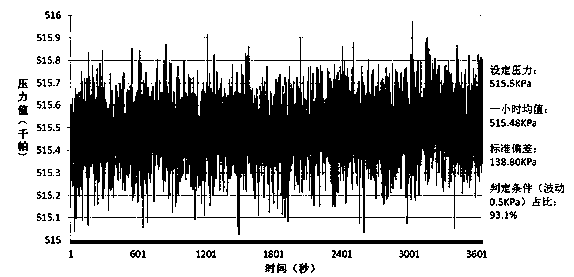

A pressure control and precision technology, which is applied in the field of ultra-high precision pressure control devices, can solve problems such as pressure loss, increased equipment costs, and high price of variable pumps, and achieves low frequency response, elimination of long-term fluctuations, and small speed fluctuations.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

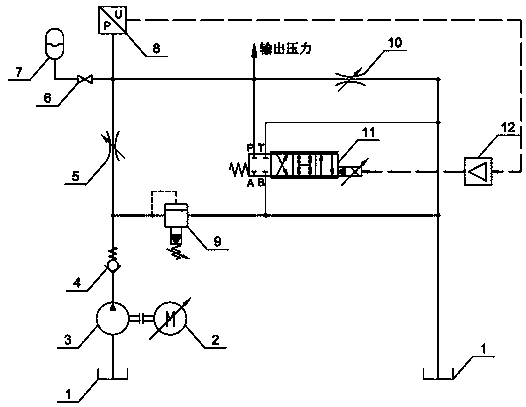

[0024] The following combination figure 2 The present invention is further introduced.

[0025] Such as figure 2 As shown, the pressure control device of the present invention includes a fuel tank, a power unit, a pressure adjustment unit, and a detection and feedback unit. The power unit includes a screw pump 3 and a servo motor 2 connected to each other; the pressure adjustment unit includes a proportional servo valve 11 and a throttle valve; The throttle valve includes a first throttle valve 10 and a second throttle valve 5 , and the detection and feedback unit includes a pressure sensor 8 and a closed-loop controller 12 . The oil outlet of the one-way valve 4, the oil inlet of the second throttle valve 5, and the oil inlet of the pilot relief valve 9 communicate with each other. Port P of the proportional servo valve 11 , the oil inlet port of the first throttle valve 10 , the oil outlet port of the second throttle valve 5 and the detection port of the pressure sensor ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com