A multi-parameter integrated sensor for monitoring generator armature windings

A technology that integrates sensors and armature windings, applied in the field of monitoring, can solve the problems of troublesome sensor installation and disassembly, heavy workload, and difficulty in current measurement, achieving the effects of convenient loading and unloading, saving time, and reducing repetitive labor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be described in detail below in conjunction with the accompanying drawings.

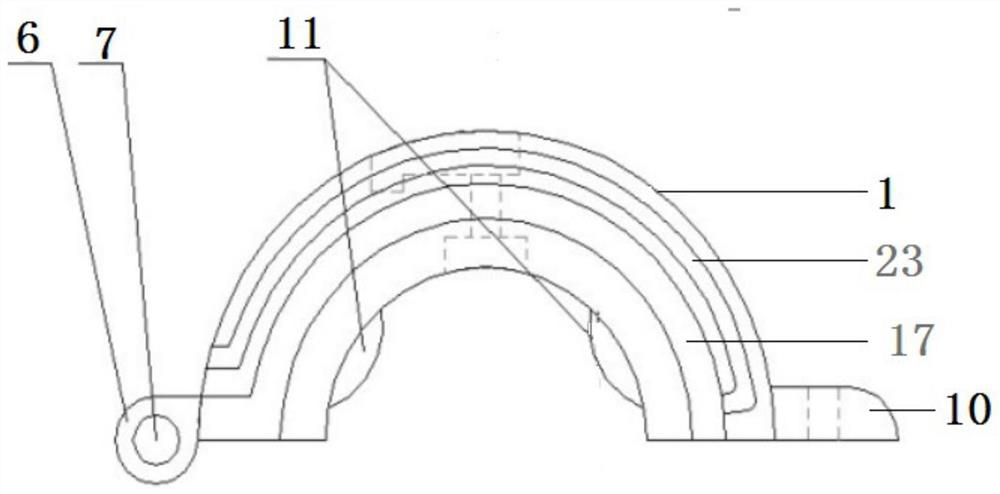

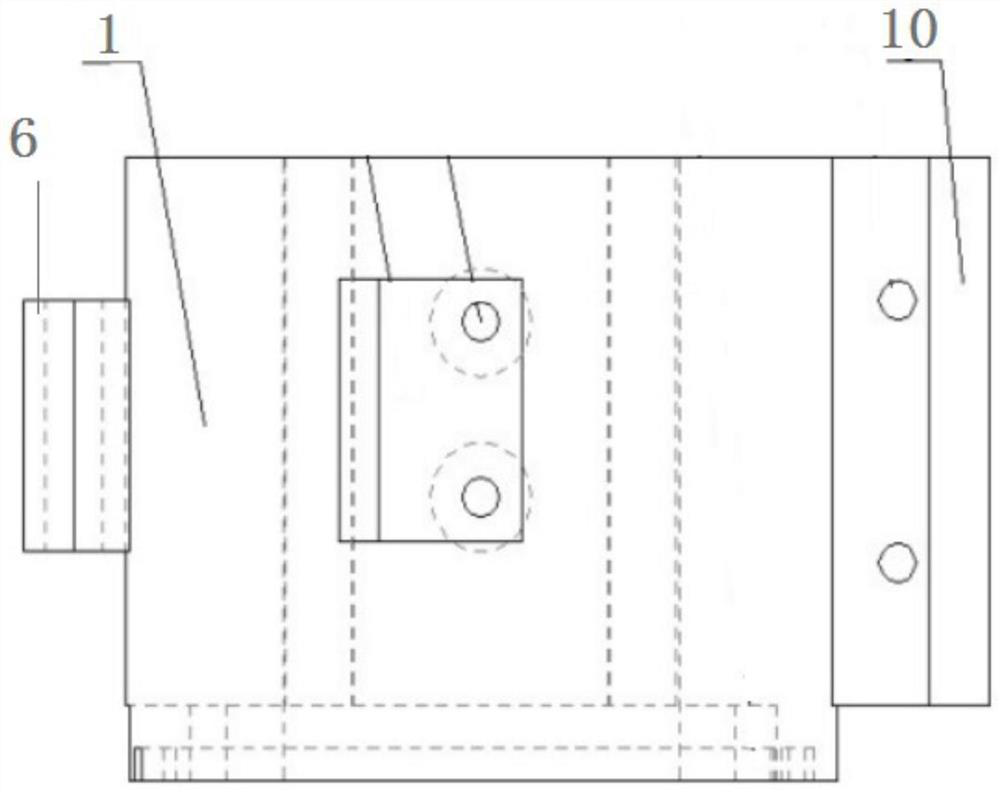

[0024] In the figure, the multi-parameter integrated sensor used to monitor the generator armature winding includes a clamping device A on which a measuring element, such as a sensor, is installed; the clamping device A includes an upper clamping part 1, a lower clamping part 2. The upper clamping part 1 and the lower clamping part 2 can be combined. After the coupling, the center of the clamping device A forms a storage space. The preferred storage space is a circular space, and the storage space is used for wrapping, Enclose the winding, which is specifically the stator winding 3 of the generator, and monitor the working conditions of the stator winding 3 by sensing the dynamic parameters generated during the working process of the stator winding 3 by the measuring element; the upper clamping part 1 and the lower clamping part 2. The combination produces a certain ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com