Pulse electric field detector with sensitivity coefficient self-calibration and power management functions and using method thereof

A technology of sensitivity coefficient and power management, applied in electrostatic field measurement, etc., can solve problems such as inability to guarantee luminous efficiency, inability to solve optical power changes, high power power of laser cooling circuits, etc., and achieve the effect of improving accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0060] The present invention will be described in further detail below in conjunction with the accompanying drawings.

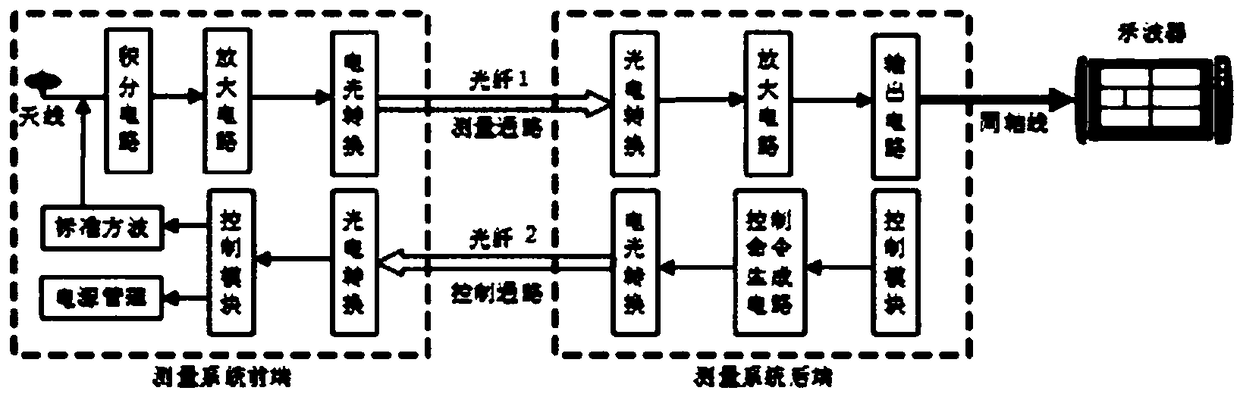

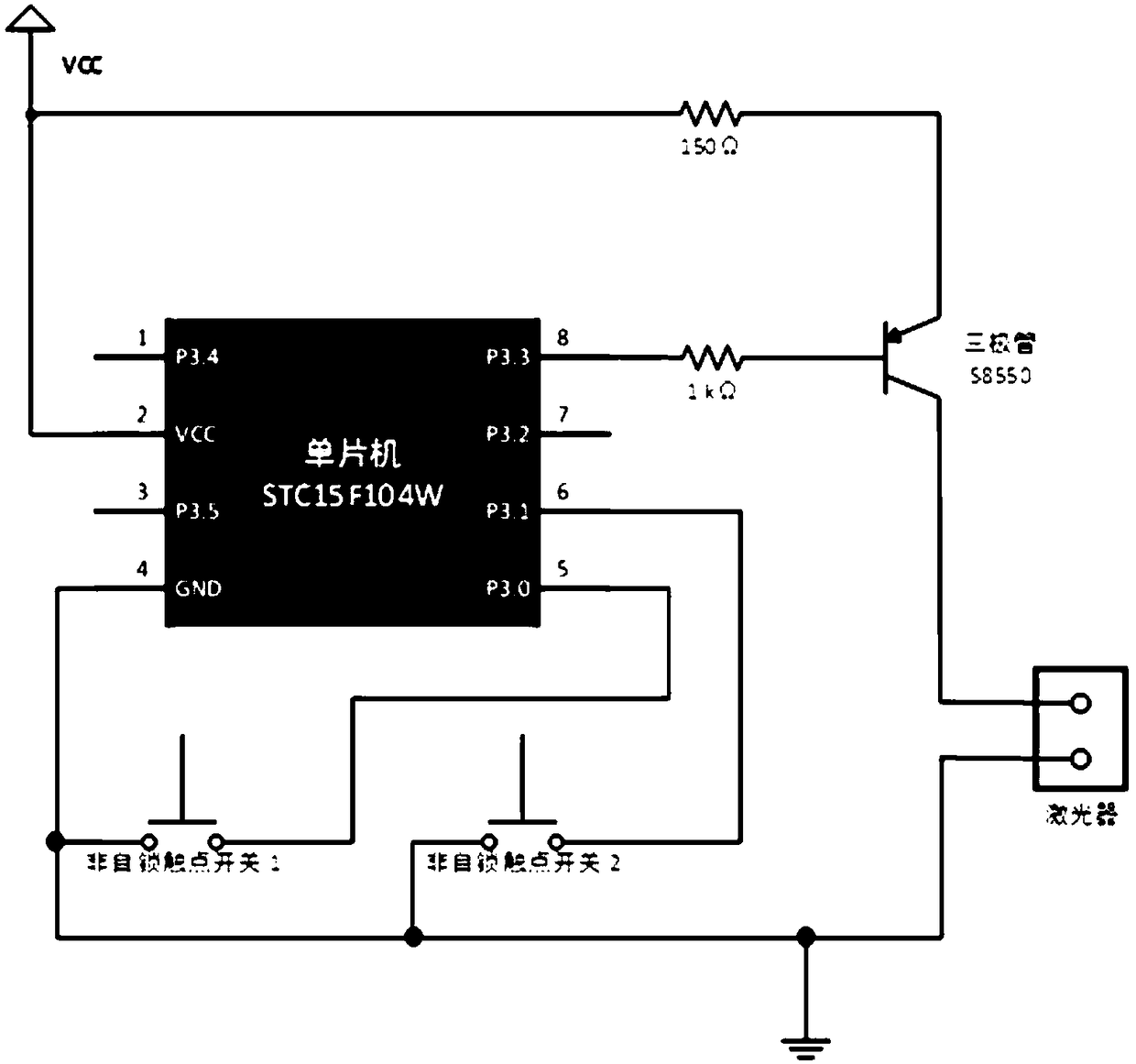

[0061] In terms of function, it includes two parts: the measurement channel and the control channel; the measurement channel adopts open technology, such as Figure 6 As shown, the basic measurement function of the pulse electric field is realized; the invention realizes the self-calibration function of the sensitivity of the pulse electric field detector through the control channel.

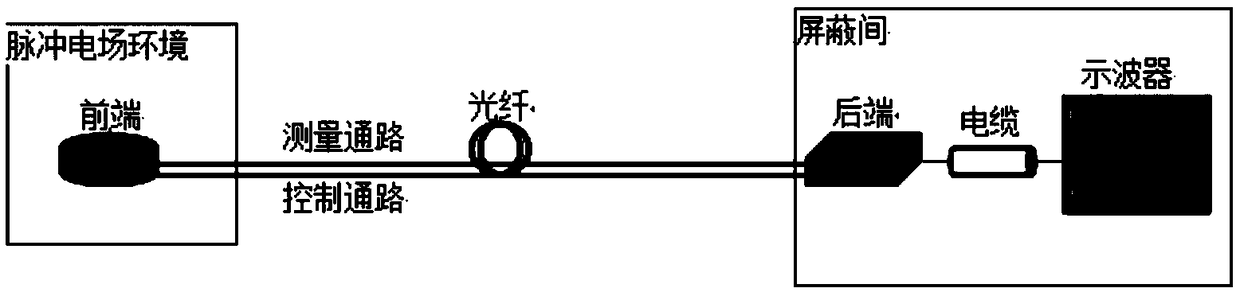

[0062] In terms of composition, the pulsed electric field detector is still divided into two parts, the front end and the back end, such as figure 1 shown. The front end and the back end of the detector need to be connected by two optical fibers, the optical fiber 1 is used for the measurement channel, and the optical fiber 2 is used for the control channel.

[0063] After adding the self-calibration function to the pulse electric field detector, the connection relationship o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com